Diagnosing New Printer Problem

Last weekend I finished assembling my i3 MK2 printer kit. Unfortunately the quality of the prints has been pretty terrible and I'm having a lot of difficulty trying to diagnose what's wrong with the printer (doubtless something I've not quite calibrated/assembled correctly).

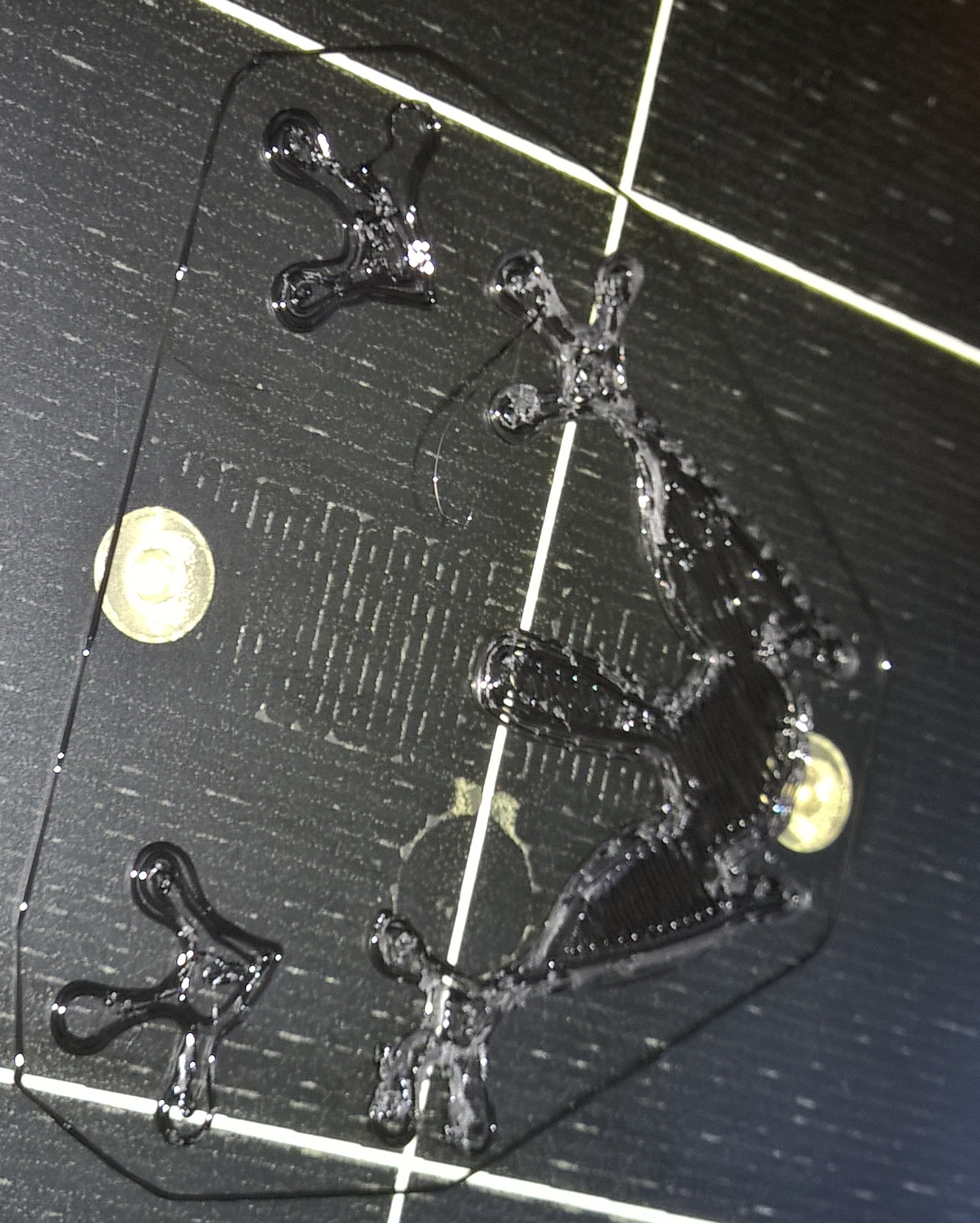

Here's a picture of the treefrog model which I just printed the first layer of and then aborted (unfortunately I have black filament, which takes terrible pictures):

Problems I can see here:

- The plastic on the left (on the outline of the print) is a bit blobby

- The outer walls (particularly around the feet) have huge gaps in them

My best guess is that this is some kind of extrusion problem. But I'm not sure what the best thing is to try next, whether I should tighten or loosen the extruder screws for example.

Re: Diagnosing New Printer Problem

💡

i don't know all your assembly imperfections, but from your picture i can at least see that the first layer is not adjusted correctly.

as stated here the v2calibration gcode is not that useful as one might expect. that's why i looked for a more reliable way to adjust it.

dem inscheniör is' nix zu schwör...

Re: Diagnosing New Printer Problem

The Z adjustment is definitely something I've spent a lot of time on (and am still not happy with). I'll try your gcode in the other thread to calibrate the Z some more. Thanks 🙂

Re: Diagnosing New Printer Problem

🙂

take the third attached gcode (that's the most convenient one) and read the thread until its end.

it's important to understand that there is a minimum in layer thickness at the best live z adjustment value.

dem inscheniör is' nix zu schwör...

Re: Diagnosing New Printer Problem

Thankyou so much! This was a far easier calibration system than the V2Calibration supplied by Prusa - I now have a functional printer after just 3 hours of trying Z-Offsets 😀