Cleaning Up Rectangular Supports on PLA

Hi,

I recently printed this model at 0.15mm resolution and rectilinear supports. The print came out very well, and everything was supported properly. However, The places where the supports touched the object perpendicularly are a little messy after pulling off the supports. How can I 1) clean it up (including the tight places) and 2) possibly adjust print settings without affecting the quality/effectiveness of the supports. I'm using Slic3r Prusa Edition.

If you're interested in what this model is, it is a reconstruction of the first discovered Naledi skull. Here it is next to the cast version.

Here is the slic3r config export for this print:

# generated by Slic3r 1.33.8-prusa3d-win64 on Tue May 9 18:08:15 2017

avoid_crossing_perimeters = 0

bed_shape = 0x0,250x0,250x210,0x210

bed_temperature = 55

before_layer_gcode =

bottom_solid_layers = 7

bridge_acceleration = 1000

bridge_fan_speed = 100

bridge_flow_ratio = 0.8

bridge_speed = 20

brim_width = 0

clip_multipart_objects = 0

complete_objects = 0

cooling = 1

default_acceleration = 1000

disable_fan_first_layers = 1

dont_support_bridges = 1

duplicate_distance = 6

end_gcode = G4 ; wait\nM104 S0 ; turn off temperature\nM140 S0 ; turn off heatbed\nM107 ; turn off fan\nG1 X0 Y200; home X axis\nM84 ; disable motors

ensure_vertical_shell_thickness = 1

external_fill_pattern = rectilinear

external_perimeter_extrusion_width = 0.45

external_perimeter_speed = 25

external_perimeters_first = 0

extra_perimeters = 0

extruder_clearance_height = 20

extruder_clearance_radius = 20

extruder_offset = 0x0

extrusion_axis = E

extrusion_multiplier = 1

extrusion_width = 0.45

fan_always_on = 1

fan_below_layer_time = 100

filament_colour = #FF14E2

filament_cost = 0

filament_density = 0

filament_diameter = 1.75

filament_max_volumetric_speed = 0

filament_notes = "List of materials tested with standart PLA print settings for MK2:\n\nEsun PLA\nFiberlogy HD-PLA\nFillamentum PLA\nFloreon3D\nHatchbox PLA\nPlasty Mladeč PLA\nPrimavalue PLA\nProto pasta Matte Fiber"

filament_settings_id =

fill_angle = 45

fill_density = 20%

fill_pattern = cubic

first_layer_acceleration = 1000

first_layer_bed_temperature = 55

first_layer_extrusion_width = 0.42

first_layer_height = 0.2

first_layer_speed = 70%

first_layer_temperature = 215

gap_fill_speed = 40

gcode_arcs = 0

gcode_comments = 0

gcode_flavor = reprap

infill_acceleration = 2000

infill_every_layers = 1

infill_extruder = 1

infill_extrusion_width = 0.45

infill_first = 0

infill_only_where_needed = 0

infill_overlap = 25%

infill_speed = 75

interface_shells = 0

layer_gcode =

layer_height = 0.15

max_fan_speed = 100

max_layer_height = 0.25

max_print_speed = 100

max_volumetric_extrusion_rate_slope_negative = 0

max_volumetric_extrusion_rate_slope_positive = 0

max_volumetric_speed = 0

min_fan_speed = 85

min_layer_height = 0.07

min_print_speed = 15

min_skirt_length = 4

notes =

nozzle_diameter = 0.4

octoprint_apikey =

octoprint_host =

only_retract_when_crossing_perimeters = 0

ooze_prevention = 0

output_filename_format = [input_filename_base].gcode

overhangs = 1

perimeter_acceleration = 800

perimeter_extruder = 1

perimeter_extrusion_width = 0.45

perimeter_speed = 40

perimeters = 3

post_process =

pressure_advance = 0

print_settings_id =

printer_settings_id =

raft_layers = 3

resolution = 0

retract_before_travel = 1

retract_layer_change = 1

retract_length = 0.8

retract_length_toolchange = 3

retract_lift = 0.5

retract_lift_above = 1

retract_lift_below = 199

retract_restart_extra = 0

retract_restart_extra_toolchange = 0

retract_speed = 35

seam_position = nearest

serial_port =

serial_speed = 250000

skirt_distance = 2

skirt_height = 1

skirts = 1

slowdown_below_layer_time = 25

small_perimeter_speed = 20

solid_infill_below_area = 0

solid_infill_every_layers = 0

solid_infill_extruder = 1

solid_infill_extrusion_width = 0.45

solid_infill_speed = 40

spiral_vase = 0

standby_temperature_delta = -5

start_gcode = M115 U3.0.10 ; tell printer latest fw version\nM83 ; extruder relative mode\nM104 S[first_layer_temperature] ; set extruder temp\nM140 S[first_layer_bed_temperature] ; set bed temp\nM190 S[first_layer_bed_temperature] ; wait for bed temp\nM109 S[first_layer_temperature] ; wait for extruder temp\nG28 W ; home all without mesh bed level\nG80 ; mesh bed leveling\nG1 Y-3.0 F1000.0 ; go outside pritn area\nG1 X60.0 E9.0 F1000.0 ; intro line\nG1 X100.0 E12.5 F1000.0 ; intro line

support_material = 1

support_material_angle = 0

support_material_buildplate_only = 0

support_material_contact_distance = 0.1

support_material_enforce_layers = 0

support_material_extruder = 1

support_material_extrusion_width = 0.35

support_material_interface_contact_loops = 0

support_material_interface_extruder = 1

support_material_interface_layers = 1

support_material_interface_spacing = 0.2

support_material_interface_speed = 100%

support_material_pattern = rectilinear

support_material_spacing = 2

support_material_speed = 50

support_material_synchronize_layers = 0

support_material_threshold = 35

support_material_with_sheath = 0

support_material_xy_spacing = 60%

temperature = 205

thin_walls = 0

threads = 4

toolchange_gcode =

top_infill_extrusion_width = 0.45

top_solid_infill_speed = 30

top_solid_layers = 9

travel_speed = 120

use_firmware_retraction = 0

use_relative_e_distances = 1

use_volumetric_e = 0

variable_layer_height = 1

wipe = 1

xy_size_compensation = 0

z_offset = 0

Thanks!

Re: Cleaning Up Rectangular Supports on PLA

Post your stl file and others may try to print it, ie me. I use Simplyfy3D mostly, but keep up with many other slicers 😉 Sometimes supports are not needed.

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Cleaning Up Rectangular Supports on PLA

Post an stl file and others may try to print it, ie me. I use Simplyfy3D mostly, but keep up with many other slicers 😉

I don't know what the distribution policy is on this model, so I don't want to upload it. However, if you make an account you can download it for free: http://morphosource.org/Detail/MediaDetail/Show/media_id/7300 . Sorry about that :/

Most if not all of the models on MorphoSource are scans, so they often need to be put through NetFabb before printing. This one seems find though; I put it directly into slic3r.

Is the way that the supports left their mark on the surface not a common problem? I've printed some other miscellaneous parts before that had the same issue.

Re: Cleaning Up Rectangular Supports on PLA

Ok DaAwesome I have downloaded the files. (I joined the site) I will see what I can do. Not immediately, I have other real life commitments ie take my wifes mother shopping. I am the only driver.

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Cleaning Up Rectangular Supports on PLA

DaAwsome Looking at the model it does need supports. The beauty with Simplyfy3d you can manually edit them. A project for me tomorrow. 😀

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Cleaning Up Rectangular Supports on PLA

DaAwsome Looking at the model it does need supports. The beauty with Simplyfy3d you can manually edit them. A project for me tomorrow. 😀

I've been considering Simplify3D for a while; I might end up getting it. Be sure to print higher res than .2 — the detail is well worth it.

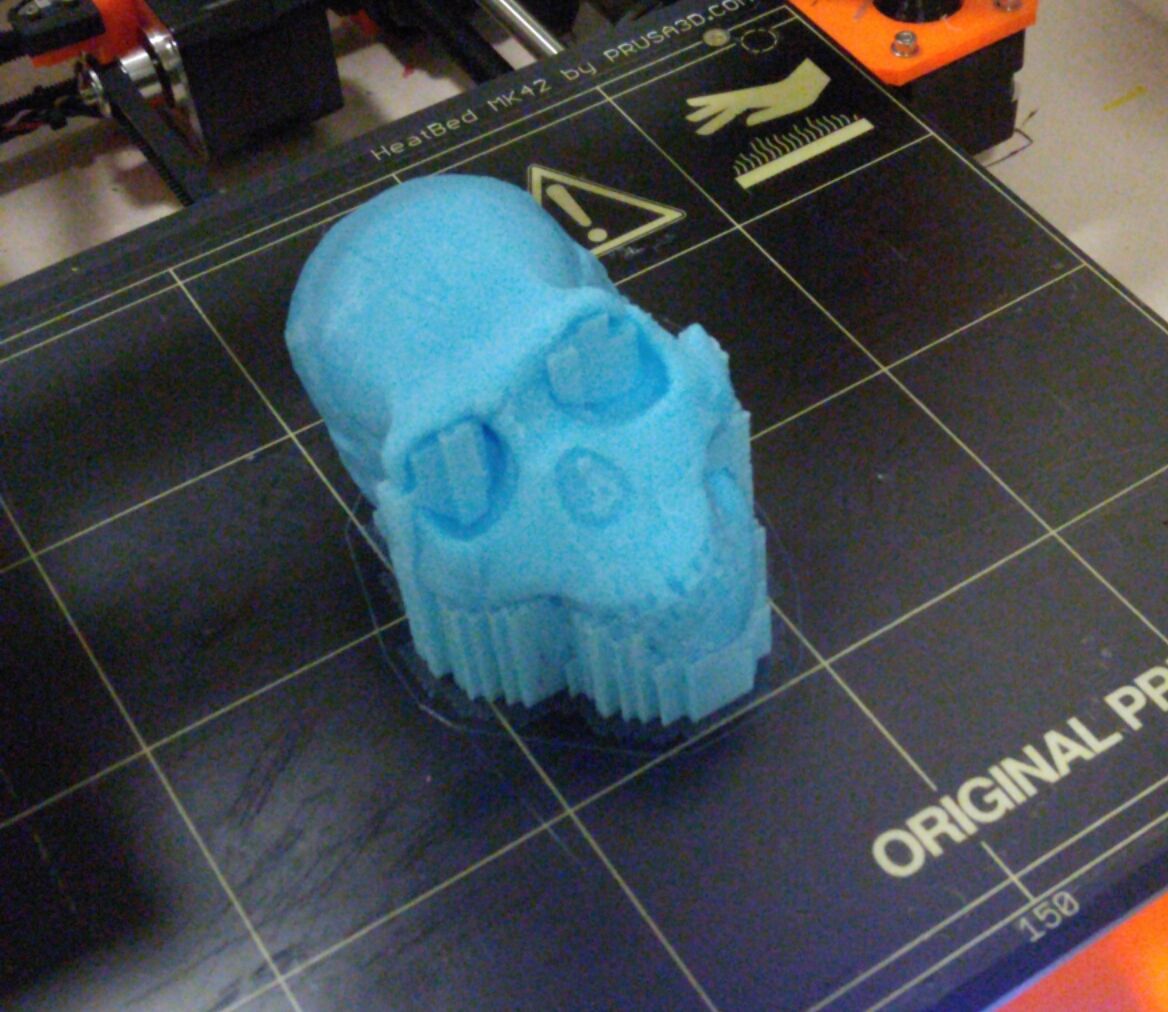

Here's how it came out for me on the bed (PLA):

Re: Cleaning Up Rectangular Supports on PLA

Your above print looks good, Were the supports difficult to remove? With Simplyfy3d you can control the density of supports and manually edit them. see Makers Muse and his 3. Surface Area, Stability and supports.

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Cleaning Up Rectangular Supports on PLA

They weren't especially hard to remove (I used needlenose pliers), but they did leave some texture left as seen in the images in the first post.

Re: Cleaning Up Rectangular Supports on PLA

I think the problem you are experiencing is the following:

https://github.com/prusa3d/Slic3r/issues/232

You may try the latest Slic3r 1.34.1, where the above mentioned issue has been resolved.

Re: Cleaning Up Rectangular Supports on PLA

I think the problem you are experiencing is the following:

https://github.com/prusa3d/Slic3r/issues/232

You may try the latest Slic3r 1.34.1, where the above mentioned issue has been resolved.

Thank you! I think that the issue may be coming from the raft. Attached is another print BEFORE I upgraded Slic3rPE with the same settings as the skull (supports and raft). One is printing right now also with the old Slic3r version but no raft (but same supports). I'll post an image of it when it finishes. For, the next print I'll print without a raft (but with supports) and with the newer Slic3r version.

Re: Cleaning Up Rectangular Supports on PLA

OK, so this is another skull with the older Slic3r and no rafts at .1mm resolution. The top and perimeters were flawless, but the supports are atrocious. I'll try out the new Slic3r version for the next print.

Re: Cleaning Up Rectangular Supports on PLA

Model is complex, it crashed Simplyfy3d a few times. Finally managed to slice it. Its printing right now. I'm printing actual size and have flipped the model 180 degrees. Quite a few hours to go yet 🙂

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Cleaning Up Rectangular Supports on PLA

PLA filament snapped.. Esun. Print abandoned. I tried. I cannot afford more hours, sorry I'll get on with my own prints.

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Cleaning Up Rectangular Supports on PLA

I can post picture of how far print got. I used 0.2 layer height, was looking ok until filament snapped.

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Cleaning Up Rectangular Supports on PLA

OK, so for my next print I used the new Prusa Slic3r version, no rafts, and 35 degree supports. Still a rough bottom, but it is much better.