Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Do you mean dimensions? I can measure it tonight.

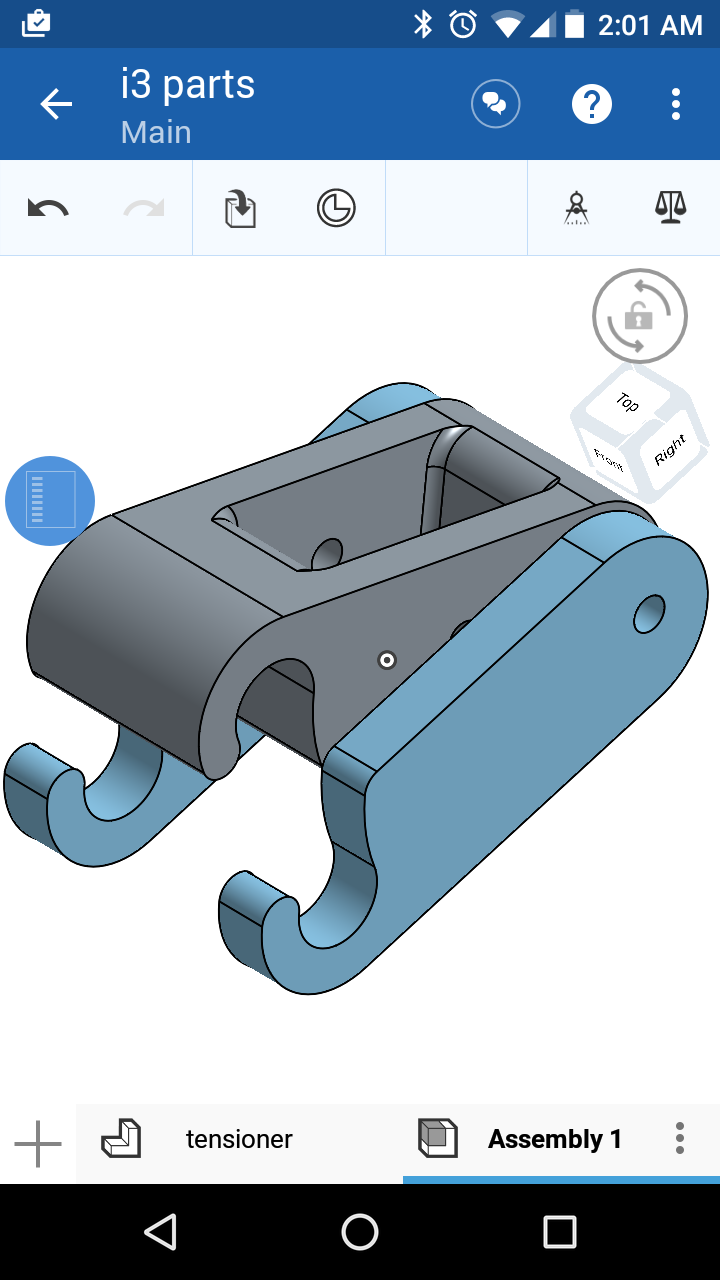

BTW I can't see any tensioning mechanism there, for me it looks like only holder. Am I missing something?

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Do you mean dimensions? I can measure it tonight.

BTW I can't see any tensioning mechanism there, for me it looks like only holder. Am I missing something?

Yeah, the dimensions please. I was approximating 20mm-ish diameter including the belt, and 10mm thickness? And 3mm shaft with some ball bearings or something.

The tensioning is in the geometry of the latch. When the latch is up (with the idler in the middle of it), the belt can be slack, and then when you close the latch, it pulls the idler back with it, thus tightening it.

I also despise the fact that I would have to disassemble the entire front end just to remove the old idler, so the new one can be installed without disassembly. And while I was at it, I figured if I have to put up with that M8 rod, I'll use it as the locking mechanism for the latch.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Now I understand it. Cool.

I'll think about something similar in my design. Current one with two M2,5 screws is pretty inconvenient, despite the fact it works.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Depends which way you are talking about it... a) When looking down from above or, b) when looking from the front.

a) This is often caused by the y-frame not fitted into the z-frame correctly. See Chapter 2, Step 3 of the Assembly Manual and make sure that distance is exactly 100mm. I used Callipers to check mine both at that stage and in the final fitting stage (Chapter 4, Step 15). If you have buit the y-frame correctly this will ensure perfect alignment.

b) This is very easy to fix, take the z-axis up until the top smooth rod of the x-axis is just level with the bottom edge of the z-frame on one side, then holding tight the threaded Lead Screw on the side that is OK slowly turn the other one until that side is level as well. A bit of 'this side, that side, this side, that side' might be needed to get it spot on.

a) Yes I tried my best but I probably messed this up, I kept measuring... Will try again. Thank you for explaining this.

b) I am afraid I don't fully understand what you are saying. Could you maybe post a picture? If it's not too much trouble...

Sorry for the very late reply!!!

For step b)

Align one end of the X-Rod A with the bottom edge of the frame B. Now holding the lead screw on the side you aligned (to stop it moving) turn the other lead screw until the whole of Rod A is aligned with Edge B. Worked perfect for me!

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Alternatively (and more easily) just use menu item "Move axis Z" to move carriage all way up until both motors skip step and you're done. 😉

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Alternatively (and more easily) just use menu item "Move axis Z" to move carriage all way up until both motors skip step and you're done. 😉

Tried that and one side was higher than the other! Hence this method...

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Then something is wrong with the printer. When carriage hits upper corners, rods shoud be parallel to top of frame. Are the top corners mounted precisely? Aren't they deformed? Any debris on printed parts? It should work like this:

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Yeah, the dimensions please. I was approximating 20mm-ish diameter including the belt, and 10mm thickness? And 3mm shaft with some ball bearings or something.

Width of idler is 9mm, outer diameter 18mm, inner diameter 15mm including belt, central hole 3mm (fits M3 screw).

Add some distance for gaps.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Then something is wrong with the printer. When carriage hits upper corners, rods shoud be parallel to top of frame. Are the top corners mounted precisely? Aren't they deformed? Any debris on printed parts? It should work like this:

No, nothing I can see... mind you I haven't tried it since I got it level my way anyway! Maybe if it goes out of whack I'll give it another go, maybe I tried it with it too far out originally.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

I should say I use the same method as you 😎 but for another reason. I just hate the sound of tormented steppers. 😉

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Yeah, the dimensions please. I was approximating 20mm-ish diameter including the belt, and 10mm thickness? And 3mm shaft with some ball bearings or something.

Width of idler is 9mm, outer diameter 18mm, inner diameter 15mm including belt, central hole 3mm (fits M3 screw).

Add some distance for gaps.

Thanks!

As far as the gantry leveling thing, you guys need to step back and understand what you are trying to achieve.

The goal is for the hotend to have a consistent height across the bed for the same Z value.

If you want to measure something, the obvious first step is to directly measure the thing you want to measure, not through a proxy (or multiple proxies).

I.e. measure the hotend's height directly above the bed.

But a direct measurement leads us back to the "thin sheet of paper" method, which everybody hates.

When you "prepare for ramming speed!", i.e. slam the gantry into the upper mounts as recommended by PR, you're indirectly measuring the hotend/bed distance by using the M3 screws at the top as a proxy for the bed position, and the printed gantry mounts/housing as a proxy for the hotend.

This is like trying to measure how tall someone is by measuring the top of his hat.

But what if he's wearing a cheese hat?

Or a cowboy hat?

What if the frame holes weren't accurate? Or the screws are messed up? Or the gantry mount/housing was sloppily printed with too much first layer squish which distorts it right at that junction?

Measuring the top of the frame to the X rods is a little bit closer, but you're still assuming the top cut of the frame is a proxy for the bed position. What if the frame wasn't cut accurately because it was assumed it wouldn't make a difference? *cough* What if the power supply you were using as an accurate frame reinforcement turned out to not be square because the manufacturer never intended for it to be a structural component of a frame? *cough*

What you want to do is get as close to the direct measurements as comfortably possible.

The X rods are a close enough proxy for the hotend provided your gantry isn't skewed/twisted.

So you want a proxy for the bed.

Technically, when you use the "paper" measure, your paper is actually a proxy for the bed. Or the hotend, depending on how you look at it.

So instead of a thin sheet of paper, why not use two precisely cut objects located on opposite ends of the bed? Two objects you know are the exact same length. Like I have a couple of extrusions at home that I know are cut to the same short length.

Put them on both sides of the bed and lower the gantry until the rod on one side just touches the reference object, which is a proxy for the bed on that side.

Then power off the z-motors (uh oh!) and turn the higher one until it just touches its reference object.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Then power off the z-motors (uh oh!) and turn the higher one until it just touches its reference object.

Motors let you turn the lead screw by hand even when they're powered, no need to switch it off.

Good post anyway.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

The problem with powering off the Z motors is that they will move to the nearest full step which could introduce a height difference between left and right of up to 40 microns (20 microns each side; if one goes up and the other down).

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

By the way I'm fighting one interesting issue (well maybe not issue, only odd fact).

I'm trying to fine tune XY home position so the print goes precisely on grid printed on the bed. But I found out I can't do that, because when I adjust endstops regarding the grid, the probe does Z autoprobing out of probing points. There is offset in Y axis about 3mm.

FW 3.0.3

Any idea?

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

The problem with powering off the Z motors is that they will move to the nearest full step which could introduce a height difference between left and right of up to 40 microns (20 microns each side; if one goes up and the other down).

I'm curious if that's any different than the "prepare for ramming speed" method where the steppers will randomly bounce off the top mounts, probably by a step as well.

By the way I'm fighting one interesting issue (well maybe not issue, only odd fact).

I'm trying to fine tune XY home position so the print goes precisely on grid printed on the bed. But I found out I can't do that, because when I adjust endstops regarding the grid, the probe does Z autoprobing out of probing points. There is offset in Y axis about 3mm.

FW 3.0.3

I think the new firmware was suppose to try to adjust and find the probe points; not sure if that changes your XY home as it does it though.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

I think the new firmware was suppose to try to adjust and find the probe points; not sure if that changes your XY home as it does it though.

I don't want to try new firmware as current one works well for me. I was just curious if it is intended feature that printed grid on bed is not related to internal grid in firmware. Funny.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

"They're more what you call guidelines than actual rules..."

In other news, the lever belt tensioner works as advertised. It's loose when up, then tightens down when locked. Overall design is sound, but I need to adjust a few things. I lost about 7mm off the Y axis as this is a little longer than the original and runs into the belt holder on the bed. Just need to trim a bit off the front and scoot the idler back a bit and hope the installer left me with enough spare belt to reach.

Fortunately the printer still probes and prints so I can print a new one up in place. Plus I don't have to disassemble the front to install the new one.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

> By the way I'm fighting one interesting issue (well maybe not issue, only odd fact).

> I'm trying to fine tune XY home position so the print goes precisely on grid printed on the bed. But I found out I can't do that, because when I adjust

> endstops regarding the grid, the probe does Z autoprobing out of probing points. There is offset in Y axis about 3mm.

> FW 3.0.3

The Y end stop triggers at Y=-4. If you extrude a line along Y=0, you will extrude roughly over the 2nd horizontal line, not along the boundary line.

> I think the new firmware was suppose to try to adjust and find the probe points; not sure if that changes your XY home as it does it though.

The 3.0.6 firmware transforms the XY coordinate system after the XY calibration has been finished and the Z calibration has been performed. Therefore it also adjusts the position of the [0,0] point.

Vojtech

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Since my MK2-X works well, it's time to publish something: http://www.thingiverse.com/thing:1692666 🙂

Still work in progress, but usable.

Done for now. Printer is assembled and works like ... well probably my best printer so far.

Added a few photos and conversion guide (well, not so sophisticated as Prusa's one, but usable I hope 😉 ), handy builder should make it with no trouble.

Still thinking about redesign of Y belt tightener as I'm about to become a bit lazy and current one works quite well. Maybe later. 😎