Any tips and tricks on how to align the smooth rod with the bed lines?

Hi,

I was nearing the end of my build when I hit a couple of issues. One is with the y-belt holder which I posted in a different thread and one is that, of course, the X-axis smooth rod is not parallel to the bed lines.

Does anyone have any tips on how to do this, other than using one's eyes :)?

Maybe by measuring some distances or something?

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Cristian

Eye is the best measuring tool we have; just make sure to adjust the correct side, otherwise the probe will not line up properly.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Depends which way you are talking about it... a) When looking down from above or, b) when looking from the front.

a) This is often caused by the y-frame not fitted into the z-frame correctly. See Chapter 2, Step 3 of the Assembly Manual and make sure that distance is exactly 100mm. I used Callipers to check mine both at that stage and in the final fitting stage (Chapter 4, Step 15). If you have buit the y-frame correctly this will ensure perfect alignment.

b) This is very easy to fix, take the z-axis up until the top smooth rod of the x-axis is just level with the bottom edge of the z-frame on one side, then holding tight the threaded Lead Screw on the side that is OK slowly turn the other one until that side is level as well. A bit of 'this side, that side, this side, that side' might be needed to get it spot on.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Depends which way you are talking about it... a) When looking down from above or, b) when looking from the front.

a) This is often caused by the y-frame not fitted into the z-frame correctly. See Chapter 2, Step 3 of the Assembly Manual and make sure that distance is exactly 100mm. I used Callipers to check mine both at that stage and in the final fitting stage (Chapter 4, Step 15). If you have buit the y-frame correctly this will ensure perfect alignment.

b) This is very easy to fix, take the z-axis up until the top smooth rod of the x-axis is just level with the bottom edge of the z-frame on one side, then holding tight the threaded Lead Screw on the side that is OK slowly turn the other one until that side is level as well. A bit of 'this side, that side, this side, that side' might be needed to get it spot on.

a) Yes I tried my best but I probably messed this up, I kept measuring... Will try again. Thank you for explaining this.

b) I am afraid I don't fully understand what you are saying. Could you maybe post a picture? If it's not too much trouble...

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Christophe posted a great couple of images and instructions and images that might help.

http://shop.prusa3d.com/forum/original-prusa-i3-mk2-f23/p-i-n-d-a-probe-misaligned-t1191.html

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

I have a list of issues I've found with the MK2 which just reached 30 items. Here are a few of them which are related to this post.

I purchased my printer pre-assembled, and it came with the cutesy Prusa Logo test print stuck on the bed. Stuck really hard. And also caused a raised bump in the PEI sheet.

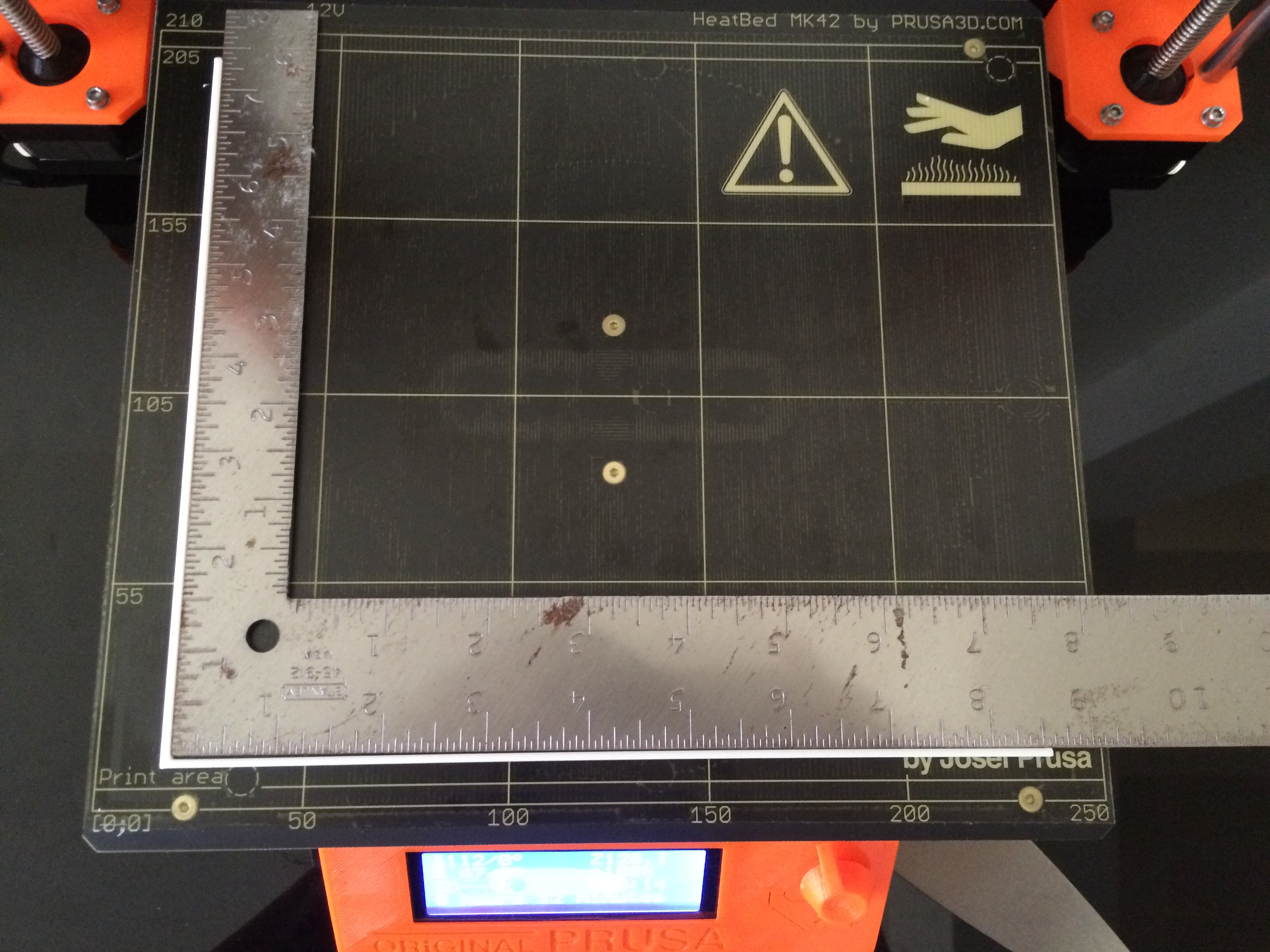

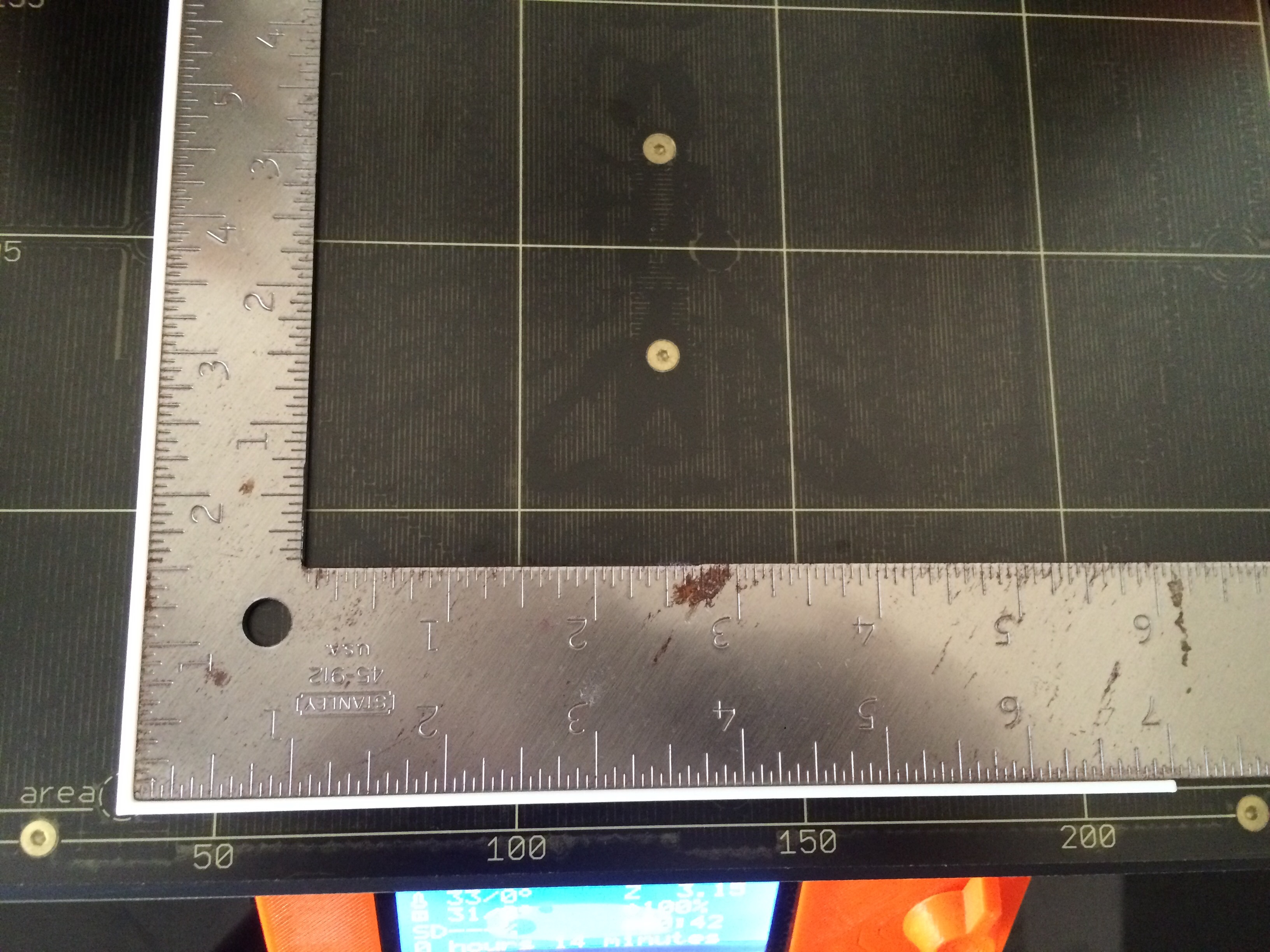

That's cute and all, but the test print I really wanted to see was this:

As you can see, my printer, from factory, has an X deviation more than 1mm across the bed, which I found unacceptable.

The prescribed way to fix it is also very unsavory because it involves distorting your y axis in order to fix what may very well be wrong in your X gantry.

But that's what you're left with.

With the current procedure, what I found helped was putting a sharpie mark on the nut so I could easily watch the number of rotations that I added/subtracted to re-shift the bed positioning.

And worked it until I got it right.

The problem is somewhat deeper though, because even if you construct the perfect Y bed, your X gantry might not line up with the bed because it itself can be distorted.

Really, the proper way to fix this is to build the perfect Y axis, LEAVE IT ALONE, and fix the X skew in the X gantry itself.

Instead, the suggested solution is to leave the X gantry alone and distort the Y axis to line up with it, which then will induce all the twist problems that people are reporting in the 10 or so other threads regarding bed leveling. Yeah, no wonder the probe can't do its job -- your process has Y travel distortion built into it.

So why would the X gantry not be lined up correctly?

Well, one reason is the printed Z mounts themselves are distorted. These untrimmed printer parts are printed with so much squish that the first layer is distorted. You can't have a squashed first layer and expect that to mate up (perpendicular) against the frame in a straight way, much less a consistent way.

If you insist on squashing and distorting the Hell out of the first layer of these prints, you should go ahead and add an inward chamfer to the first layer to compensate for the distortion. A 1-2 layer chamfer will still leave you with plenty of surface area to stick to the bed, yet prevent the distortion.

But building in x gantry adjustment (or at least validation in the build process) would also help.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

gz1, great analysis. And agreed that it shouldn't be this hard.

What is the difference in measurement between the front face of the z frame to the Z axis rod for both of the X gantry attachments?

Have you tried placing a 1mm shim underneath the x gantry attachment on the right side?

If that worked, then it would obviate the need to distort the bed.

In the ideal world there would be ways to finely adjust the X and in my case, the Z to make Z perpendicular to the bed.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

gz1, great analysis. And agreed that it shouldn't be this hard.

What is the difference in measurement between the front face of the z frame to the Z axis rod for both of the X gantry attachments?

Have you tried placing a 1mm shim underneath the x gantry attachment on the right side?

If that worked, then it would obviate the need to distort the bed.

In the ideal world there would be ways to finely adjust the X and in my case, the Z to make Z perpendicular to the bed.

The difference between the front face and the Z axis rods was slight, but also somewhat difficult to measure. On top of that, however, is the fact that the Z axis rods are really only a proxy for the X axis rods, which are the true concern and can themselves deviate from the Z axis rods (through distorted printed parts). But are also kind of tricky to measure. I tend to believe if you want to measure something, you measure it directly, not through a proxy of another-thing-that-can-also-have-error-in-it.

I did consider shimming the mounts on the right side so i can return the Y axis to its correct state, but that would actually require a lot more disassembly than I wanted to undertake at the time. There's little point of buying a pre-assembled printer if I have to literally disassemble the whole thing to fix it.

If I go through that level of disassembly, I'm going to fix multiple things at the same time. Like the issue with the distorted parts and also the lack of a proper belt tensioner. And the fact that the lead screw nuts should be on the bottom, not the top of the carriage.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

I think there is only one ultimate solution of all MK2 geometry problems - completely different frame. Mine is currently work-in-progress. I will make all STL files public when the work is finished. Currently working on Y motor holder and idler.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Surely something like that is just as prone to problems as the method Prusa have used? The cuts at the end of the frame pieces have got to be 100% accurate or the frame will distort again, in the X, Y and Z directions. It will be more fiddly to get the smooth rods to be 100% aligned on the Y-axis. It seems to me that rather than correcting all the faults of the existing design it just swaps them for different ones.

To be honest the only way to get a 100% accurate frame in all directions, every time will be if Prusa design a one piece, precision milled part! The price though would be prohibitive. The method they use at the moment is pretty much as good as it gets for a kit form 3D printer at a reasonable price!

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

It seems to me that rather than correcting all the faults of the existing design it just swaps them for different ones.

First try then judge. 😉 It is rigid enough to stand supported on only 3 corners with 2 spools of filament on top and still the XY plane is perfect flat. Plastic corners are joints only, the structure itself is based on metal parts touching metal parts. Precision of this assembly is beyond the precision of my measuring tools.

Of course frame milled from one piece is winner of precision contest, but of highest price contest as well, unfortunately. I'm trying to stay in hobby-level design.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Actually that is a very good use of aluminium extrusions and one which has been proven to work very well for the size as pictured.

And it is quite amazing how accurate these things can be even with relatively large tolerances in the materials.

The cross section of the extrusion is where the accuracy and strength comes from and I think that David will soon be back here reporting his build success!

The only thing to be wary of is rotational movement between top and bottom which may require additional bracing at 2 key points.

One other thing I would now consider is the use of lead screws for the X and Y axis to remove the belt compression tension from the machine; OK, they won't be quite as fast as the belts, but they should work fine, especially if fitted with backlash suppressors.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Surely something like that is just as prone to problems as the method Prusa have used? The cuts at the end of the frame pieces have got to be 100% accurate or the frame will distort again, in the X, Y and Z directions. It will be more fiddly to get the smooth rods to be 100% aligned on the Y-axis. It seems to me that rather than correcting all the faults of the existing design it just swaps them for different ones.

To be honest the only way to get a 100% accurate frame in all directions, every time will be if Prusa design a one piece, precision milled part! The price though would be prohibitive. The method they use at the moment is pretty much as good as it gets for a kit form 3D printer at a reasonable price!

Actually, it is better for one obvious reason:

It is really, really easy to get precision cut extrusions nowadays which will easily surpass hand-assembled threaded M8 and M10 nuts and bolts.

The rest of the interface parts can be accurately 3d printed as long as you aren't obnoxiously sloppy when printing them.

And getting things *adjusted* to be correct will be way easier with an extrusion setup. Like getting those y-axis smooth rods perfectly aligned? Dead simple. Adjusting the smooth rods on the current I3? Painful and annoying.

The real reason for doing "all precision milled 1-piece parts" is actually to ease assembly. So the guy doing the assembly can just throw everything together and neither validate nor adjust the parts he assembles. Kind of like how the guy who assembled my printer kind of threw everything together but didn't validate that it was correct.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

The only thing to be wary of is rotational movement between top and bottom which may require additional bracing at 2 key points.

Are you talking about Z frame absorbing shocks from moving X-carriage? Yep, I'm little bit worried about it, because extruder assembly is rather heavy. We'll see. Used frame assembly is actually from RebeliX project, where this was no issue. I hope it will be no issue here as well.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Yeah. Worst case brace from the rear Y corners to the top of Z frame.

Twisting could otherwise happen when printing/moving fast.

Add the braces and it won't go anywhere...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Well, it looks like no braces will be necessary. The prototype is working and ... so far so good. 🙂 No noticeable twisting.

I used longer bearings LM8LUU, the bed is now rock solid (the play is literally zero) and I am able to adjust it absolutely precisely.

There is only one problem making me a little bit upset - the cable from right Z stepper is too short to keep cable management tidy. But mechanical parts work better than expected.

A lot of work still incomplete - electronics mount, PSU mount, display mount, implement belt tensioner to Y-idler, etc.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

That's good news.

I have an idea regarding the belt tensioner. Instead of trying to make it continuously adjustable, just make it a cam lever that pulls back on the idler by a couple of mm. That's all you really need. To adjust tension you can change how many teeth overlap in the loop, comfortably install the belt, then pull down on the lever to tighten. I have a design I've been playing around with but I need to work out the geometry.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Sounds promising. I really look forward to your design. Meanwhile I did some belt tensioning updates to current Y-idler (screw based), because one tooth precision on the belt is too rough for me. One tooth less is too loose, one tooth more is too tight. 😆 I don't want the frame be unnecessarily stressed.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

Since my MK2-X works well, it's time to publish something: http://www.thingiverse.com/thing:1692666 🙂

Still work in progress, but usable.

Re: Any tips and tricks on how to align the smooth rod with the bed lines?

David

Brilliant!

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…