ABS+ printing problems

I don't know what to do anymore... Im getting terrible prints from ABS+, pictures below.

My M92 settings are X100.32 Y100.60 Z396.66, they work perfect with PLA and worked fine with the first 25% of the first try, so I don't think it's that.

Fan is always off and the bed is 90 (producer recommended), but even with 100 it doesn't change anything.

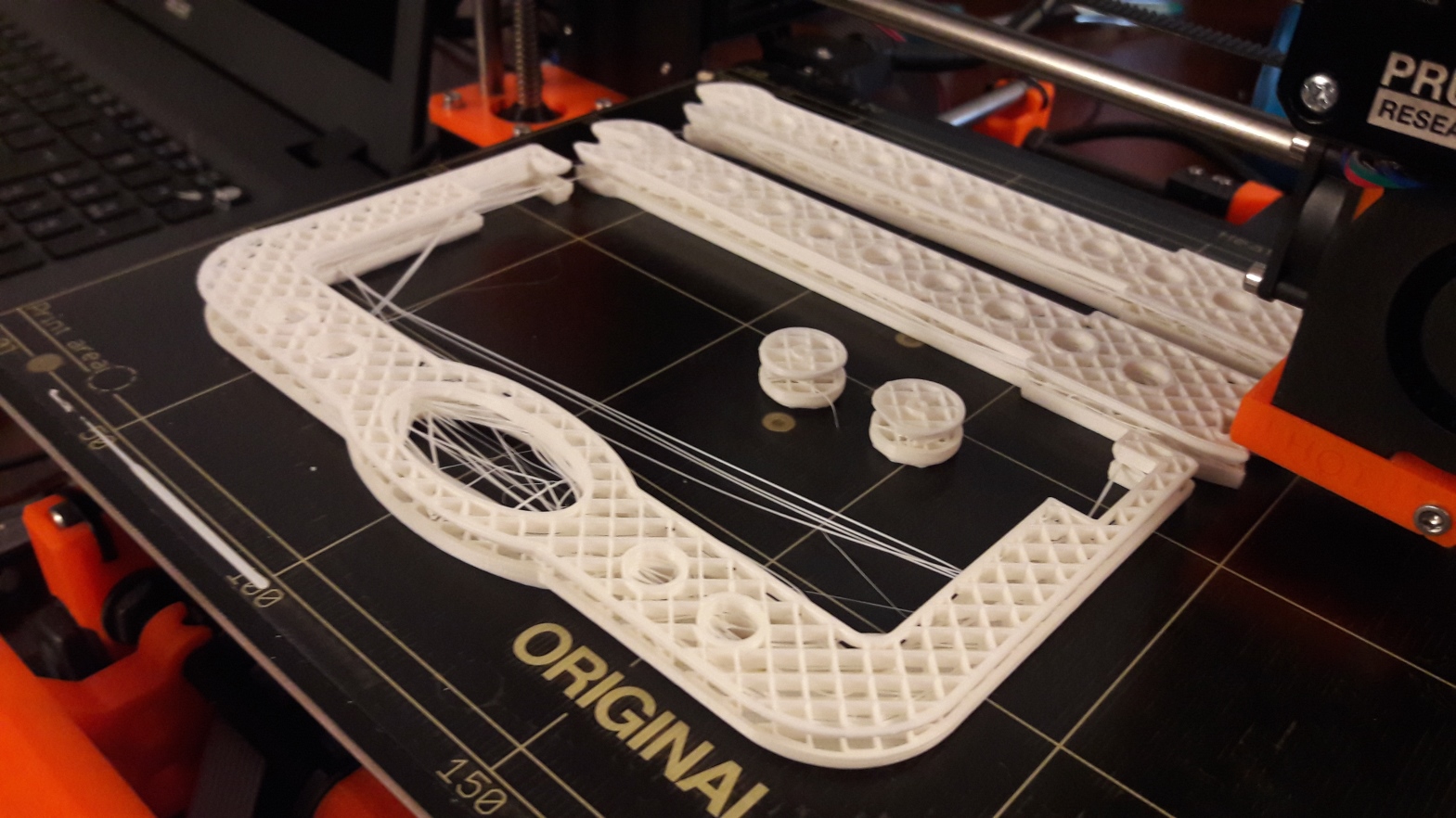

First I tried printing this filament holder. The first 25% went great, but then something happened...

I try some tweaks. Less success. I revert to the old setting, but add a raft. No success.

Thinking it might be Simplify3D, I change to Slic3r.

The strange thing is that all these lines are on the same layer. The circles in the middle and the first shell prints like it should. But the second shell mess things up.

Does anyone have any idea what could be wrong?

Re: ABS+ printing problems

Why did you change steps/mm in Z axis? Just curious. Because it is very unlikely that Z lead screws don't have exact 8mm pitch.

BTW interesting print issue. At first picture it looks like after a few printed layers whole print started again from beginning.

Re: ABS+ printing problems

Yeah and if you are going to change the Z steps, you need to ensure that your layer height will result in a full microstep, otherwise some layers will be taller than others with the same extrusion.

Go back to a simple model known to work. If that prints badly then you will know it is the printer playing up, otherwise it is either the model or slicer settings.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: ABS+ printing problems

Yeah, I'll print something easy tomorrow, Peter.

I reset the Z steps to 400 but that was not the problem.

Oh, well. At least it is a functional part 😆

Re: ABS+ printing problems

I think the problem is that your printer setting for the Z axis is wrong. For ABS (for me it works) the Z level should be little bit lower than for PLA. For PLA I have -0.500, for ABS it is about -0.850. Another problem with ABSwas bed - it has to be super clean. IPA is very reliable cleaner.

Re: ABS+ printing problems

The initial Z calibration for PLA at 55 or 60C bed temperature won't apply to ABS.

After few printing failures with ABS, I ran Z calibration when the heated bed was at 100C, then did Live Z adjustment during a test printing.

For PLA the Z offset I made was -0.800 mm. For ABS, new Z offset was -1.250 mm.

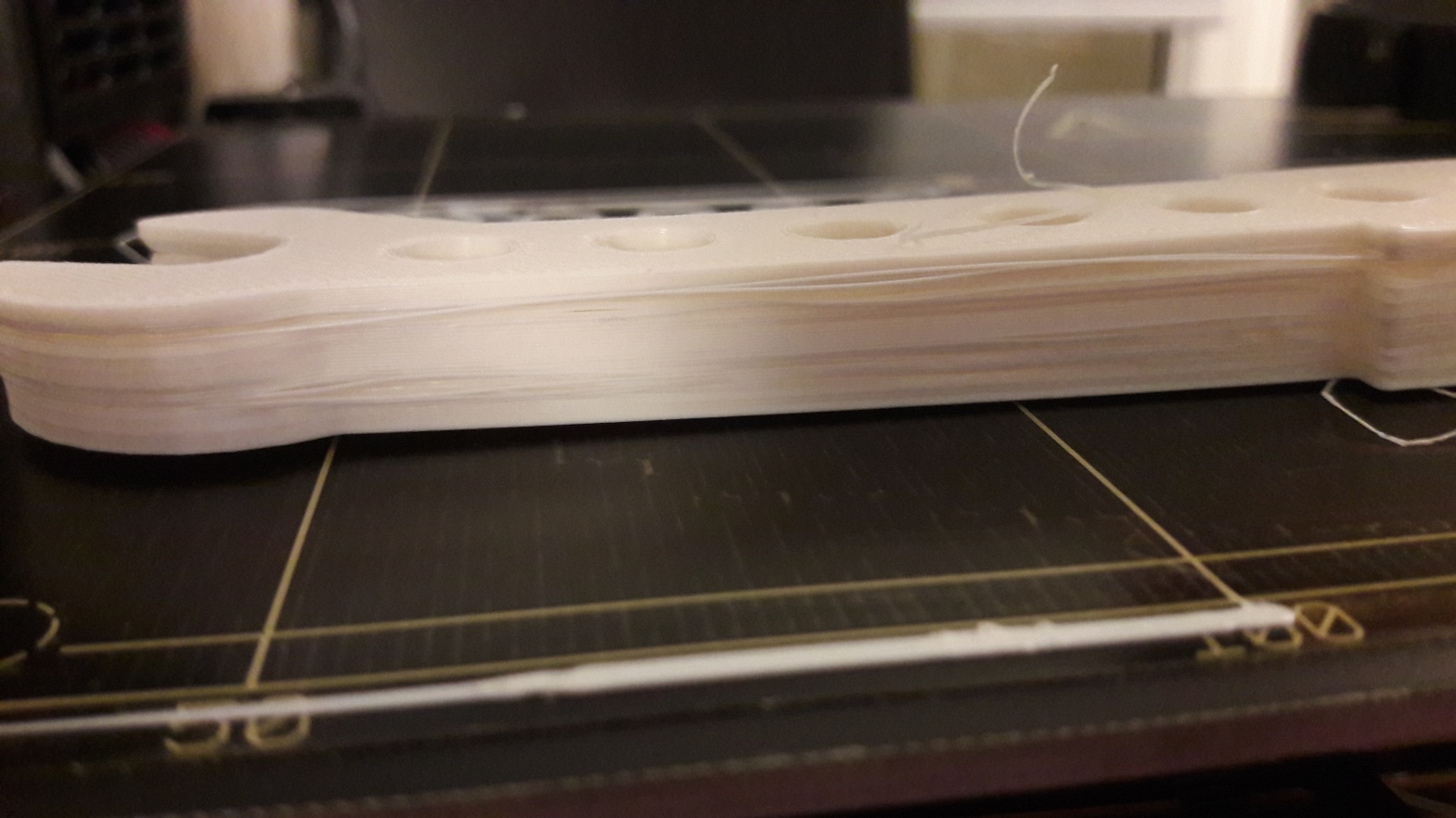

Also naked PEI surface doesn't provide strong adhension for big printed parts. The edges were tend to lift.

So I started applying one layer of glue stick before printing a new model and it has been worked out.

Brim helps adhesion too. The minimum brim width I use is 5 mm.

I've printed twenty some parts in ABS without a failure.

Re: ABS+ printing problems

It's certainly a Z problem, not a filament problem. I'm going to make a new thread about it so it is easier to find for people having the same problem.

Edit: Here is the new thread

Thanks for all the help 🙂

Re: ABS+ printing problems

I think the problem is that your printer setting for the Z axis is wrong. For ABS (for me it works) the Z level should be little bit lower than for PLA. For PLA I have -0.500, for ABS it is about -0.850. Another problem with ABSwas bed - it has to be super clean. IPA is very reliable cleaner.

This would only explain first layer adhesion problems, wouldn't it?

Re: ABS+ printing problems

Yes, but if the first layer is not OK then also other layers are hanging in the air. Another problem could be draught around the printer cooling filament too much (friend experience).

Re: ABS+ printing problems

My baby, what have you done to my baby 😳

Joke apart, it does not look like an adhesion issue to me.

Your first print looks like a step shift, and the tweaks you have done after that seems to have introduced additionnal issues.

First thing to do would be to prevent it is to double check anything that can temporary block the bed or the extruder (cable management, perfect square angle everywhere. Did the XYZ calibration warn about some skewing?

In addition going from quiet mode to power mode will give more tolerence to small mecanical issues., but consider it more like a workaround than a full fix.

Additionnal point: Since these part tend to warp a bit on ABS, adding a PINDA hat will help to avoid the PINDA to catch some uplifted part and to make it slide under it, which can also be an explanation of your initial step shift.

I'm like Jon Snow, I know nothing.

Re: ABS+ printing problems

Does the printer save a different live Z adjust value for each different material (based on our preheat selection)?

I'm guessing not...

Chris

Re: ABS+ printing problems

^ don't think so Chris

Re: ABS+ printing problems

Was thinking about it some more while we were running errands. It seems that the firmware could do some kind of algorithmic adjustment of the Z-height based on the temperature delta. So, if you set the Z-height at 215 degrees, the firmware should be able to predict what the correct Z-height should be when printing ABS filament at 240, or at 255?

Or at the very least, the firmware could remember the correct Z-heights from previous Z-height adjustments at various temperatures that the user determined, and reuse them when the same temperatures are used again?

Chris

Re: ABS+ printing problems

Chris

I think it's more do do with the temperature of the bed and probe (changing inductance due to heat) more than expansion.

And that depends on where the probe is in relation to the bed when pre-heating.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: ABS+ printing problems

If that is the case, it seems like the firmware could just remember the last live Z adjust value for that print head temperature and print bed temperature?

Chris

Re: ABS+ printing problems

Chris

The firmware is open source, which means that you are able to make any changes to it that you require.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: ABS+ printing problems

For me, the Hatchbox ABS printing problem appears to maybe be fixed by raising the bed temperature to 100 C, and by lowering the Z-adjust to -715. I'm using extruder temperature 230 C

Chris

Re: ABS+ printing problems

Then the next print failed, with what looked like a step shift, like when the extruder and heated bed cables used to collide (but now I have cable chains), and some of the prints came loose from the bed. I forgot to raise the print bed temperature up to 100 C. I will also try the high power mode...

Chris

Re: ABS+ printing problems

After reading more on this Prusa forum, got it printing reliably (I hope) with Hatchbox ABS. Had to lower the live Z adjust quite a lot more, use a 5mm brim, raise the bed temperature, and go to high power mode (resists mechanical problems better). Nozzle at 240 C, bed at 100 C, live Z adjust at -.742

Re: ABS+ printing problems

That's way better !

What slicer did you use so that these ABS setting were not the baseline from the start ?

And remember, "failing is learning" 🙂

I'm like Jon Snow, I know nothing.