Spool Placement

I asked this in the other forum, before I saw this one. 😳

What is the placement for the spool holders? From the assembly instructions it looks like they would have to go behind the printer. I have no room there! Where can they go? Above would be best, followed by to the side.

Thanks,

--Colin

Re: Spool Placement

Hi Colin,

the spool placement is best behind using our spool holders. If you lack place, you can place it above the printer. In general, check if the extruders can pull the filament easily.

/ Knowledge Base

The guy behind Prusa assembly manuals...

Re: Spool Placement

Thanks for the reply!

What are the dimensions of the spool holder?

Re: Spool Placement

Colin

The spool holders I have are about 24 x 22 cm, but there are two of them. They can be placed either side of the printer.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Spool Placement

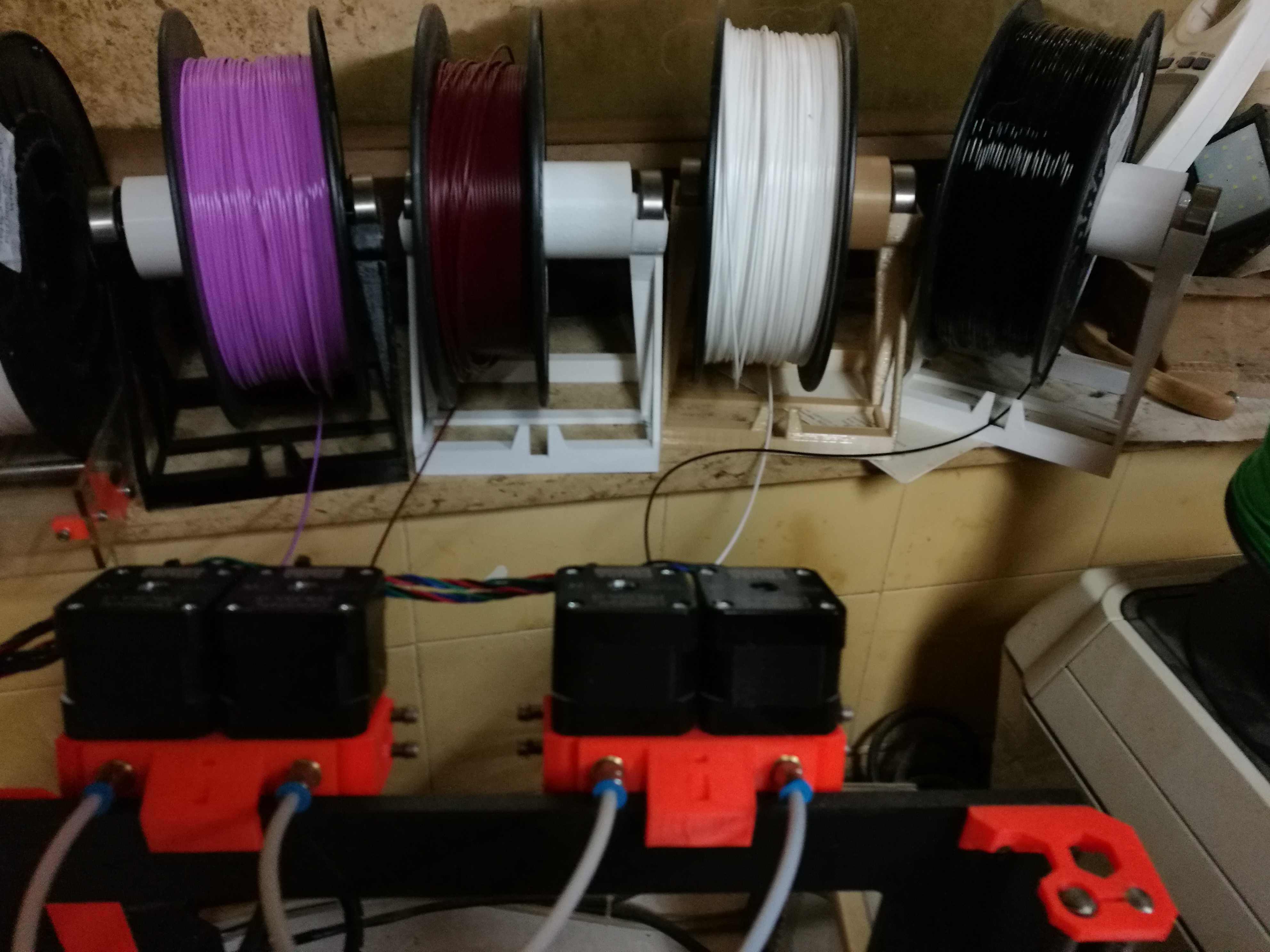

any picture how it may look like ?

dem inscheniör is' nix zu schwör...

Re: Spool Placement

any picture how it may look like ?

Here you go...

The printer has one spool holder to its left (currently loaded with only one spool of black) and the other to the right on the windowsill (loaded with PVA and white).

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Spool Placement

damned... seems that i've to tidy up my "print desk" and make room for the required spool holders...

dem inscheniör is' nix zu schwör...

Re: Spool Placement

Jeff

You can print something that will work for you.

The standard config has PTFE tubing between spool holder and extruder motor which is not totally necessary:

There is also a downside in that on unload, the filament is pushed back onto the spool and some manufacturers provide narrower spools which are totally filled up; the unload can cause the filament to run off the edge of the spool and jam on subsequent loading. I solved this by cutting the PTFE feeder tubes in half, which prevents unloading back to the spool (see the white filament on previous picture).

If you can hang the spools on the wall behind your printer, I think that would be the best solution.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Spool Placement

I should also mention if you were wondering about the pink filament, the reason why. It was purchased especially for this print:

Peter

EDIT: I should add that the large Cheshire Cat is a 45 hour print... It really is not one that should be attempted until you have the upgrade working properly!

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Spool Placement

My problem is I have no room behind the printer on my desk. I have to be careful or the heatbed cables hit the wall.

I'm sure that as these get into people's hands we'll have plenty of options come up. I'm thinking a shelf on the wall above the printer, with some nice LED lighting on the bottom. 😀 Perhaps with the filament exiting the bottom instead of the front.

Those cats look great. If I would have tried to do that on my old dual-extruder machine, it would be covered with blobs.

Re: Spool Placement

My problem is I have no room behind the printer on my desk. I have to be careful or the heatbed cables hit the wall.

That is exactly my problem

I'm sure that as these get into people's hands we'll have plenty of options come up. I'm thinking a shelf on the wall above the printer, with some nice LED lighting on the bottom. 😀 Perhaps with the filament exiting the bottom instead of the front.

Yes, that was one solution which has already been implemented

Those cats look great. If I would have tried to do that on my old dual-extruder machine, it would be covered with blobs.

Unfortunately, there are several points in the print where you need to use 4 filaments in the same layer; simply not possible on a dual extruder system.

As it happens, both the cats pictured were sliced with KISS; the ones sliced with Slic3r are slightly better with regards to "blobs" and show fewer issues caused by model errors, but print time is somewhat extended.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Spool Placement

Here is a drawing, dimensions are 226x219x45 mm

/ Knowledge Base

The guy behind Prusa assembly manuals...

Re: Spool Placement

Has anyone with an enclosure for their printer been included in the beta testing? If so, do they have any pictures they could share of their setup?

Re: Spool Placement

Where are these new spool holders obtained? ... are they included in the MMU kit?

Re: Spool Placement

Where are these new spool holders obtained? ... are they included in the MMU kit?

Yes, included in the kit.

Re: Spool Placement

I have an idea!

A wire shelf like this one: http://www.homedepot.com/p/ClosetMaid-24-in-White-Versatile-Hanging-Shelf-8279/100181563

Hang it on the wall behind the printer, with the bottom of the shelf not too high above the top of the printer. Then use the stock spool holders, but feed the filament from the back of the spool through the bottom of the holder, through the shelf, and to the extruder motors. This should give a gentle curved path for the filament to feed.

Re: Spool Placement

Has anyone with an enclosure for their printer been included in the beta testing? If so, do they have any pictures they could share of their setup?

Sorry Richard, not that I am aware. However, the motors can get quite warm; driving warm filament may be an issue if the filament reaches GTT.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Spool Placement

Sorry Richard, not that I am aware. However, the motors can get quite warm; driving warm filament may be an issue if the filament reaches GTT.

Peter

Not too worried about temperature. In all the printing I have done the max internal temp of my enclosure was 40c. I'm more concerned with additional height from the new motors and spool placement/filament patch issues.

Currently I have a rather small 3" diameter hole in the top of my enclosure where I feed the filament through. I can enlarge this but I'm not sure about spool placement.

Re: Spool Placement

Richard

You only need 4 x 4mm PTFE tubes to go from the spool holder to the motors. Theoretically the PTFE feeder tubes can be quite long; to reduce the drag on unload I would have a short piece of tubing from the motors to outside the case and then a longer piece to the spool holder. Filament would then be unloaded to the gap in the tubing which would be taken up again on loading. Loading and unloading is where the motor power is increased somewhat.

The motors are only 2" taller than the frame, but when printing tall objects the Bowden tubes will go a few inches above that level.

With some prints, my motors were getting to about 45 degrees, about 25 degrees above ambient. That would mean 65 degrees at 40 ambient. Heat will travel along the motor shaft to the drive gears and soften the filaments (especially PLA) so you may need additional motor cooling.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Spool Placement

Hi, placed mine left and right to the printer, about half way back. no issues with that by now.

Christian