PVA recommendations

With my MM upgrade, I've started to play with PVA supported prints. Surprisingly, I've not found any comprehensive information about using various brands of PVA on the Prusa. If it exists, please point me at it.

In the meantime I thought I'd write up my experiments using Rigid Inks PVA. I have a roll of MatterHackers PVA on route so I'll write up a comparison once I've tried it. Any feedback or other detailed PVA experience appreciated. I love Rigid Ink's stuff, but can't say I feel this particular PVA is easy to use.

Rigid Ink PVA

The material is transparent, slightly yellow, and very rigid. I've heard some PVAs are quite soft but this is much closer to PLA in stiffness. I found it slightly tricky when feeding into the machine - like it was on the thicker side of what the feeder was happy with - but it does feed once you get the hang of it.

The quoted range for print temperatures is 190-210C with bed 50-60C. The more extensive documents from Rigid Ink also suggest a print speed of 30mm/s and running a slow cooling fan.

For me I've found this stuff to be extremely fussy. It's not particularly keen to stick to the bed, and once persuaded to do that, it's not very keen to stick to itself. I've had to slow the print speed way down - 10mm/s - to get this stuff to stick reliably, especially on layers 2 and above. This also means slowing down the move speed otherwise the print head would drag the newly printed filament off the bed/previous layer (I set the maximum non-printing speed to 40mm/s - the default is 120mm/s). I've set the bed to 70C for the first layer otherwise it would not stick, dropping this to 60C for later layers. I've set the filament temperature to 205C. I tried prints from 190C up to 220C. At 190C the filament just won't stick to itself at all. That seems to improve as it gets hotter, with 205C being the lowest temperature where the results were consistent and acceptable. I'd rather not run this stuff too hot.

The resulting supports are hard after printing, just like the starting filament. This is not a PVA you can peel off. But it does disappear slowly when placed in water as one would expect.

Re: PVA recommendations

Glue stick on the bed really does assist with adhesion.

But there shouldn't be much PVA on the bed, if you are printing only the interface in that material.

I tested eSun which is very flexible and also has inconsistent diameter. With that, the lower temperature the better and remember to use it up very quickly; it starts to go off within a few days.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: PVA recommendations

I've not tried eSun but I'll add it to my list. I'm not using it just for interfaces because the things I'm printing has internal channels which I need supporting. I can't get to these by hand so dissolvable is ideal. I keep the material in a sealed box (humidity ~ 4%) and feed it to the printer via an extra bowden tube to limit moisture exposure. No popping noises so far.

Re: PVA recommendations

With my MM upgrade, I've started to play with PVA supported prints. Surprisingly, I've not found any comprehensive information about using various brands of PVA on the Prusa. If it exists, please point me at it.

In the meantime I thought I'd write up my experiments using Rigid Inks PVA. I have a roll of MatterHackers PVA on route so I'll write up a comparison once I've tried it. Any feedback or other detailed PVA experience appreciated. I love Rigid Ink's stuff, but can't say I feel this particular PVA is easy to use.

Rigid Ink PVA

The material is transparent, slightly yellow, and very rigid. I've heard some PVAs are quite soft but this is much closer to PLA in stiffness. I found it slightly tricky when feeding into the machine - like it was on the thicker side of what the feeder was happy with - but it does feed once you get the hang of it.

The quoted range for print temperatures is 190-210C with bed 50-60C. The more extensive documents from Rigid Ink also suggest a print speed of 30mm/s and running a slow cooling fan.

For me I've found this stuff to be extremely fussy. It's not particularly keen to stick to the bed, and once persuaded to do that, it's not very keen to stick to itself. I've had to slow the print speed way down - 10mm/s - to get this stuff to stick reliably, especially on layers 2 and above. This also means slowing down the move speed otherwise the print head would drag the newly printed filament off the bed/previous layer (I set the maximum non-printing speed to 40mm/s - the default is 120mm/s). I've set the bed to 70C for the first layer otherwise it would not stick, dropping this to 60C for later layers. I've set the filament temperature to 205C. I tried prints from 190C up to 220C. At 190C the filament just won't stick to itself at all. That seems to improve as it gets hotter, with 205C being the lowest temperature where the results were consistent and acceptable. I'd rather not run this stuff too hot.

The resulting supports are hard after printing, just like the starting filament. This is not a PVA you can peel off. But it does disappear slowly when placed in water as one would expect.

MatterHackers PVA

The material is semi-transparent; much yellower than the Rigid Ink PVA, and much softer; soft like a flexible PLA rather than a NinjaFlex. Feeding it into the machine was easy and the diameter of the filament seems very close to the PLAs I use. I was concerned that the softness might be an issue, but it fed easily without adjustment.

The quoted range for print temperatures on the website is 185+/-15C (so 170C to 200C) but the spool states 190C to 220C. I ran the filament with the default support speed settings and PLA-style fan settings. The bed temperature was 70C (1st) and 60C (the rest).

Initially I set the PVA temperature to 190C and my PLA to 210C. Both printed just fine, the PVA feeding and sticking the bed as one would hope. Unlike the Rigid Ink PVA, the second layer stuck perfectly to the first. However, the PVA quickly jammed by forming a large "knot" at its end making it too big to feed back into the extruder when it was needed. I'm not sure why this was (will look into this more) but I theorized that running both filaments at the same temperature might help. So the subsequent runs have been done with both PVA and PLA at 210C and - fingers crossed - no blockages so far. At the higher temperature the PVA stick to the bed, and sticks to itself without a problem, but it does seems a little more stringy. I may experiment with dropping both PLA and PVA to 205C to see if that helps.

The resulting supports are quite soft and much of it can be easily pulled away from the PLA. The rest disappeared fairly quickly in an ultrasonic cleaner at 50C. Most of it was gone in a couple of hours.

Re: PVA recommendations

With my MM upgrade, I've started to play with PVA supported prints. Surprisingly, I've not found any comprehensive information about using various brands of PVA on the Prusa. If it exists, please point me at it.

In the meantime I thought I'd write up my experiments using Rigid Inks PVA. I have a roll of MatterHackers PVA on route so I'll write up a comparison once I've tried it. Any feedback or other detailed PVA experience appreciated. I love Rigid Ink's stuff, but can't say I feel this particular PVA is easy to use.

Rigid Ink PVA

The material is transparent, slightly yellow, and very rigid. I've heard some PVAs are quite soft but this is much closer to PLA in stiffness. I found it slightly tricky when feeding into the machine - like it was on the thicker side of what the feeder was happy with - but it does feed once you get the hang of it.

The quoted range for print temperatures is 190-210C with bed 50-60C. The more extensive documents from Rigid Ink also suggest a print speed of 30mm/s and running a slow cooling fan.

For me I've found this stuff to be extremely fussy. It's not particularly keen to stick to the bed, and once persuaded to do that, it's not very keen to stick to itself. I've had to slow the print speed way down - 10mm/s - to get this stuff to stick reliably, especially on layers 2 and above. This also means slowing down the move speed otherwise the print head would drag the newly printed filament off the bed/previous layer (I set the maximum non-printing speed to 40mm/s - the default is 120mm/s). I've set the bed to 70C for the first layer otherwise it would not stick, dropping this to 60C for later layers. I've set the filament temperature to 205C. I tried prints from 190C up to 220C. At 190C the filament just won't stick to itself at all. That seems to improve as it gets hotter, with 205C being the lowest temperature where the results were consistent and acceptable. I'd rather not run this stuff too hot.

The resulting supports are hard after printing, just like the starting filament. This is not a PVA you can peel off. But it does disappear slowly when placed in water as one would expect.

MatterHackers PVA

The material is semi-transparent; much yellower than the Rigid Ink PVA, and much softer; soft like a flexible PLA rather than a NinjaFlex. Feeding it into the machine was easy and the diameter of the filament seems very close to the PLAs I use. I was concerned that the softness might be an issue, but it fed easily without adjustment.

The quoted range for print temperatures on the website is 185+/-15C (so 170C to 200C) but the spool states 190C to 220C. I ran the filament with the default support speed settings and PLA-style fan settings. The bed temperature was 70C (1st) and 60C (the rest).

Initially I set the PVA temperature to 190C and my PLA to 210C. Both printed just fine, the PVA feeding and sticking the bed as one would hope. Unlike the Rigid Ink PVA, the second layer stuck perfectly to the first. However, the PVA quickly jammed by forming a large "knot" at its end making it too big to feed back into the extruder when it was needed. I'm not sure why this was (will look into this more) but I theorized that running both filaments at the same temperature might help. So the subsequent runs have been done with both PVA and PLA at 210C and - fingers crossed - no blockages so far. At the higher temperature the PVA stick to the bed, and sticks to itself without a problem, but it does seems a little more stringy. I may experiment with dropping both PLA and PVA to 205C to see if that helps.

The resulting supports are quite soft and much of it can be easily pulled away from the PLA. The rest disappeared fairly quickly in an ultrasonic cleaner at 50C. Most of it was gone in a couple of hours.

E3D Scaffold

This material is grey, quite stiff, and a little rough to the touch. It feeds into the machine easily and without any fuss.

The quoted range for print temperatures is 190 to 220C with a bed of 20C to 55C. I ran the filament with the default support speed settings, the hot end at 210C and bed at 70C. The bed temperature is higher than the quoted range, but E3D claim Scaffold is okay up to 110C - just not ideal - and these temperatures are what I've been using for my PLA. For the moment I wanted to avoid changing the hot end temp when switching material; this had caused blockage problems in previous material tests.

Having been stung by the hard Rigid Ink PVA not working for me, I was worried about this material, but it works like a charm. It worked so well and so easily that I suspect it really is quite tolerant of different print conditions (as E3D claim) and I will experiment at some point in the future to see if this really is the case. There was some stringing, which seemed to increase as the layer high increased, but not as much as with the MatterHackers PVA. I didn't tweak the default retraction settings to see if that would help. I am concerned that Slic3r is ignoring the fan settings for the support material which seems like a bug.

The resulting supports are quite hard - much more similar to PLA than a flexible material. And, true to the claim that this stuff will break away from your print, it does just that quite easily. I couldn't remove all of it from my model this way as it has some internal channels, but it makes sense to remove as much as possible before putting in water. Once in water the material is a little different from MatterHackers PVA. The remaining Scaffold became soft very quickly - maybe only 30 minutes in an ultrasound cleaner - and it was easy to remove using toothpicks. The difficult to reach bits took many hours to dissolve completely, so this stuff seemed to soften quickly, but dissolve slowly. It's not a bad compromise.

Finally, this stuff is relatively expensive with 500g costing $60, compared to MatterHackers PVA which is $45. Time and experimentation will tell if its worth the premium.

Re: PVA recommendations

Very interesting read. Thanks for doing the homework and reporting it.

Re: PVA recommendations

Tim,

Thank you so much for doing this type of testing for us, and reporting it here. A great help and resource.

I am about embark on MMU work and am considering what soluble support to try first, and your posts are a great help.

A couple of quick question:

1) With a month since your last post, have you refined your opinion of any of these?

2) Have you tried the Verbatim BVOH?

Again, thank you for doing this. It really helps make the community better.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: PVA recommendations

I've mostly been using the MatterHackers PVA, although I've not been doing much work requiring soluble support in the last month. I still have occasional blockages when switching materials, especially if the material are at different temperatures (even if those temperatures are within the material range of each). I'm still debugging retraction settings to see if I can improve this.

Verbatim BVOH - not tried it, but might take a look.

Thanks.

Re: PVA recommendations

I have now tried the Verbatim BVOH, and wanted to share my experience.

TL/DR: Verbatim BOV is expensive, works great, and needs cooler printer temps (205/205) than default. Recommended.

Verbatim BVOH:

The stuff is NOT cheap. But using the "SOLUBLE INTERFACES" setting on Slic3r does not use very much of it. More on that below. That said, I am very happy with the results.

Settings: The default settings in "mk2mm_Slic3r_prusa3D_1_8_0.ini" (that came in the 1_9_0 distribution) has the temperature settings for this material at 215/210. This cause immediate clogs just below the steel tubes, and a printer clogs. Changing it to 205/205 created perfect extrusion and no clogs. Using the "SOLUBLE INTERFACES" setting on Slic3r worked perfectly. It put BVOH just between the supports and model (top and bottom of the support if supported from the model not the bed). This minimized BVOH usage - I used the default settings and they worked perfect (checked carefully on the preview). This setting has the BVOH and the PLA with 0 distance between - they fuse together.

The Test Print: It is a mask with a curved underside, which requires support over 95% of the internal surface (which will be in contact with my face so I really didn't want the pokes of normal supports.) Some small parts on the front also required supports (supported from the model not the bed) also. Some of the interfaces are on flat surfaces, some are in little nooks and crannies of small features. Utilized 3 colors + BVOH, and a 21:22:34 hour print.

The Result: The BVOH prints very well (once I changed the temperature settings above). When I removed the print from the printer the BVOH was very solid, and I could not remove the supports. Everything looked good. I ran some warm water and placed the print under it. In less than a minute, the support pieces started to fall off. With a bit of mechanical action, and re-emersion the supports were all off in under 3 minutes, and the now exposed BVOH came right off the surfaces with a finger rub under water. It softens very quickly - and dissolves (water turns milky) very soon after. Surface finish (above and below) is as good as any surface except the squashed bottom (glassy) finish. Total cleanup time ~5 minutes to a very nice finish. Very happy. (Wish my model was better - but I am am working on that - the printer only prints what I tell it.)

BTW, the model is mostly BLACK, so it was very easy to see if any (white) BVOH was stuck anywhere. It came of very quickly and easily and did not require me to "work it" in any area - even areas with a bunch of features. It just dissolves.

Bottom Line: If you need soluble supports (and some models do) the Verbatim BVOH is an expensive solution that works VERY well. I recommend it and will keep using it.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: PVA recommendations

I just started using Scaffold Support Material and was having some trouble using it. I used 215/55 the same as my PLA setting in order to avoid changing the temperature. I used SOLUBLE INTERFACE setting in order to save it. It turned out that, when printing the interface on the PLA supports, the scaffold was not sticking to my PLA tightly enough. I assume I need to adjust its material settings in fan speed and max movement speed.

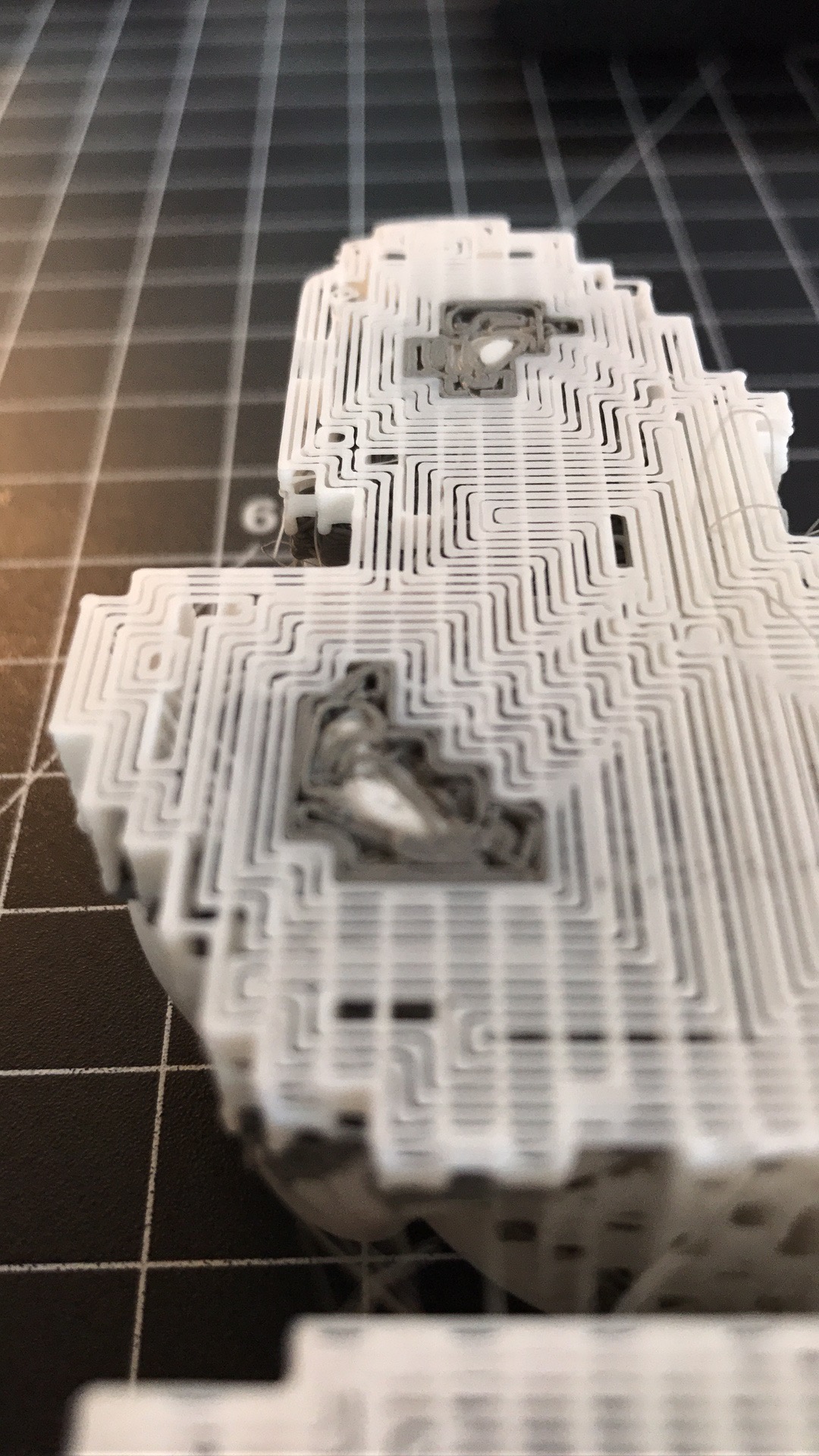

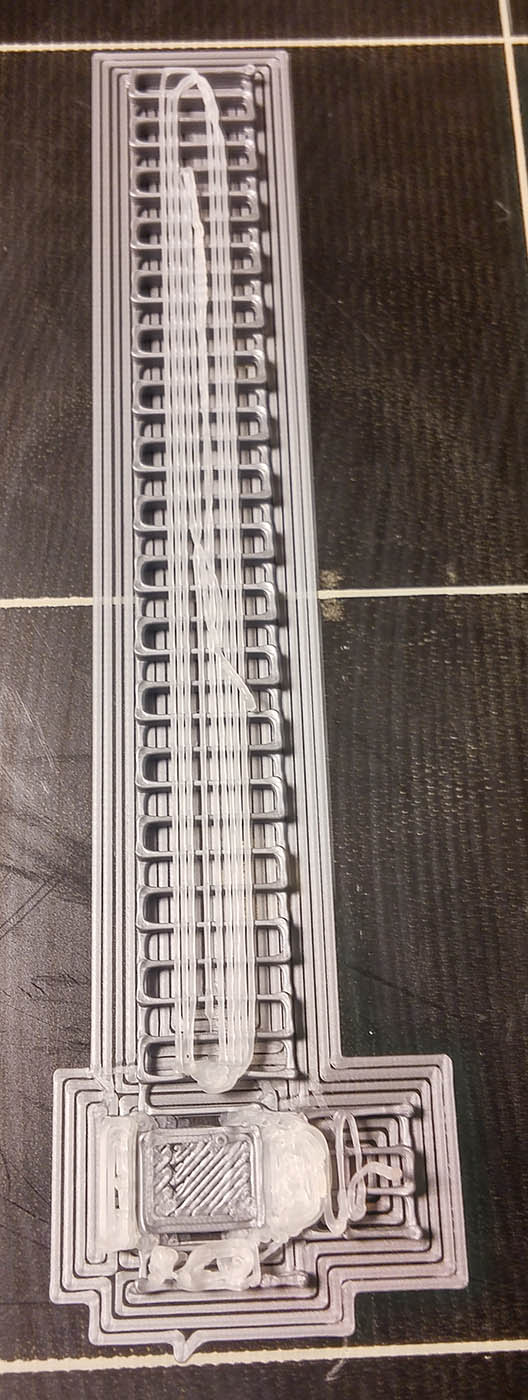

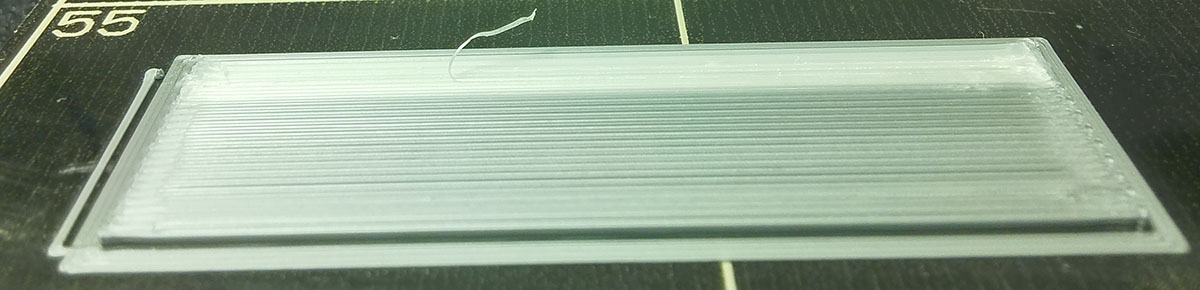

P1: The Sacffold (in grey) was not attached to the heat bed well enough, though the temperature was totally within recommended and not changed.

P2: I went for a nap and this was what I got left in the morning -- the upper part was all spaghetti. Have to fix it by starting printing the upper part.

P3: Here is how the material switch block looked like. The Scaffold didn't even attach to itself well enough on its "cleaned" (messiest) side.

Hope to hear more about you guys' experience with Scaffold.

Re: PVA recommendations

I still have most of my Scaffold spool(I've been using the MatterHackers PVA exclusively) so I can re-try some scaffold in the next few days. Did you try increasing the bed temp (I've only used it at 70C) and making sure the fan was really off? When I was doing my original tests, Slic3r just ignore the fan setting on the support material.

Re: PVA recommendations

Had chance to print a few test cubes today, but only in Scaffold (not in Scaffold and PLA). I found a bed of 70C and filament at 215C worked well, although I think it'd have been even better if I'd slowed down the print speed. I'll try to print a combination print tomorrow.

Re: PVA recommendations

I have not used Primaselect PVA, only Verbatim BVOH, but the default temperature settings were not good for me. It looks like you might need to add 5 deg to the PVA (?) to get it to flow better (?). (I had to drop the temp on BVOH to prevent clogs.)

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: PVA recommendations

@aaron.s5 Thanks a lot for flow tip - yesterday i had done my best try with pla+pva and it almost finished but in the middle was some layer shift and after that rest of print messed up - probably the reason was moment when printer is changing filament on wipe tower ( when it's sliding in line few times then nozzle is ripping already extruded pva - almost every time)

Conclusions:

- tried wide range of temperatures of primaselect pva+ (180-230) - best resoults were on 180 (?)

- increase flow - 120%

- slower support extrusion - about 30 mm/s

- i'll try to dense supports for better adhesion

Questions:

- is there possibility to change support extrusion speed only for pva ( support interface )?

- where i can find settings for wipe tower in slic3r?

- default prusa's preferences for primaselect pva+ wont work for me in slic3r and control - maybe my printer assembly is wrong - where should i search for another causes of my issues?

Re: PVA recommendations

You can set setting for each filament under the Filament Settings. Make sure under advanced that "Soluble material" is checked.

Each extruder also has settings, under Printer Settings.

The Wipe Tower has few settings, just enable, position, width, and per color change depth. (under Multiple Extruders under Print Setting).

I expect Slic3r development is rapidly changing around soluble interfaces, and the like, so patients will pay off. They have come a long way.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: PVA recommendations

I gave the Esun PVA a try due to the fast shipping on amazon. I used it in conjunction with Esun PLA+ but am going to try later with the Atomic PLA. This PVA prints acceptably I'd say but I've not tried any other brands yet. It definitely has a lot of stringing / oozing at the default extruder settings. I found these settings to minimize the stringing to a tolerable level where it doesn't typically affect your print:

Temp: 200C (any lower and it sometimes clogs)

Fan: 85-100% (PLA defaults)

Retraction : 2mm

Zlift: 0.1mm

Retraction speed: 120mm/s (don't know if that actually speeds it up)

Deretraction Speed: 50mm/s

Wipe enabled with 60% wipe

Couple of observations:

-I had to dry this filament because on the 1st print it steamed a bunch. I also now print it straight out of a desiccant container with a teflon tube running to the printer

-It doesn't stick to the bed very well so I try to avoid it for 1st layers. I haven't messed with bed temps too much though or using glue sticks.

-Adhesion to PLA isn't very strong. You can pretty much peel it off without water or much effort. It hasn't caused an issue with a print yet but I imagine it might at some point

-When I originally tried this stuff without cooling on, it printed like crap. It got better adhesion but the quality was terrible and I was failing wipe towers a bunch

-It dissolves in warm water pretty fast

-I found I liked the quality on the underside of my prints most if I set the interface pattern spacing to 0mm. I didn't try to much there though to optimize

Re: PVA recommendations

If you just want it to work without any hassle, buy Verbatim BVOH.

It prints at 205, which is what I use to print PLA. I've never had it clog and it feeds perfectly in my 2 months of using it. It is very expensive, but the quality of the print turns how so much better. It dissolves in water very fast and a lot of the time it just peels off the print without any need for water. Prusa recommends it for a reason, there's even and preconfigured option in Prusa Slic3r.

Re: PVA recommendations

Rigid Ink PVA with Prusa Research PLA

Using the PVA as the interface material for the supports of a very small and very detailed model less than 35mm cube using Original Prusa i3 MK2S MMU.

- First issue i had was the pva not sticking to the bed when the prime line is carried out as per the prusa firmware.

- Second issue i had was the PVA curling up and not bonding to the PLA on the raft, model or wipe tower.

- Third issue was that the PVA caused a blockage each and every time i print was running causing it to fail and clearing to be made.

I did a little research on the following links,

https://shop.prusa3d.com/forum/original-prusa-i3-mk2-multi-material-f26/pva-recommendations-t4982-s10.html

https://www.rigid.ink/more

Within the links i had found that temperature of the PVA differs vastly from each company and that causes an issue itself when printing alongside other materials in a single extruder multi-material system due to the 4 into 1 manifold with the temperature changes between each.

Due to this i kept my PLA and PVA settings at the same temperature and continued to make adjustments.

My findings:

-Colder the PVA the worse it adheres to anything and the worse it is to extrude (links say otherwise)

-Hotter the PVA the better it extrudes and the more like PLA in printability it becomes.

-PVA will not stick to the bed unless bed temperature is very high which then is and issue for PLA suitability. (using PEI sheet)

First was to get the print to stick to the bed so i put the raft material as PLA and set it at 2.

This enable a surface for the PVA to adhere and worked well.

I began at 210/55 nozzle/bed with standard extrusion as per Slic3r (1.0) and worked from there.

Dropping to 200/55 caused even higher curling and no adhesion.

Raising to 215/60 allowed the PVA to adhere to the PLA and an okay layer however was not extruding enough and failed on the wipe tower bridging.

Raising again to 220/60 ext-1.1 proved better although still not great

Raising again to 225/60 ext-1.4 on both proved the best so far.

I am able to build a model however at this temperature for the PLA with the extrusion the same as the PVA caused high squishing creating a wider PLA extrusion making the tolerance between supports and model (Contact-Z Distance) non existent.

Keeping with 225/60 but PVA-ext-1.4 and PLA-ext-1.3 made the extrusion width of the PLA slightly thinner and more like normal settings.

I am currently printing this model and will upload pictures of the state soon and any further adjustments thereon