Oozing/ribbing

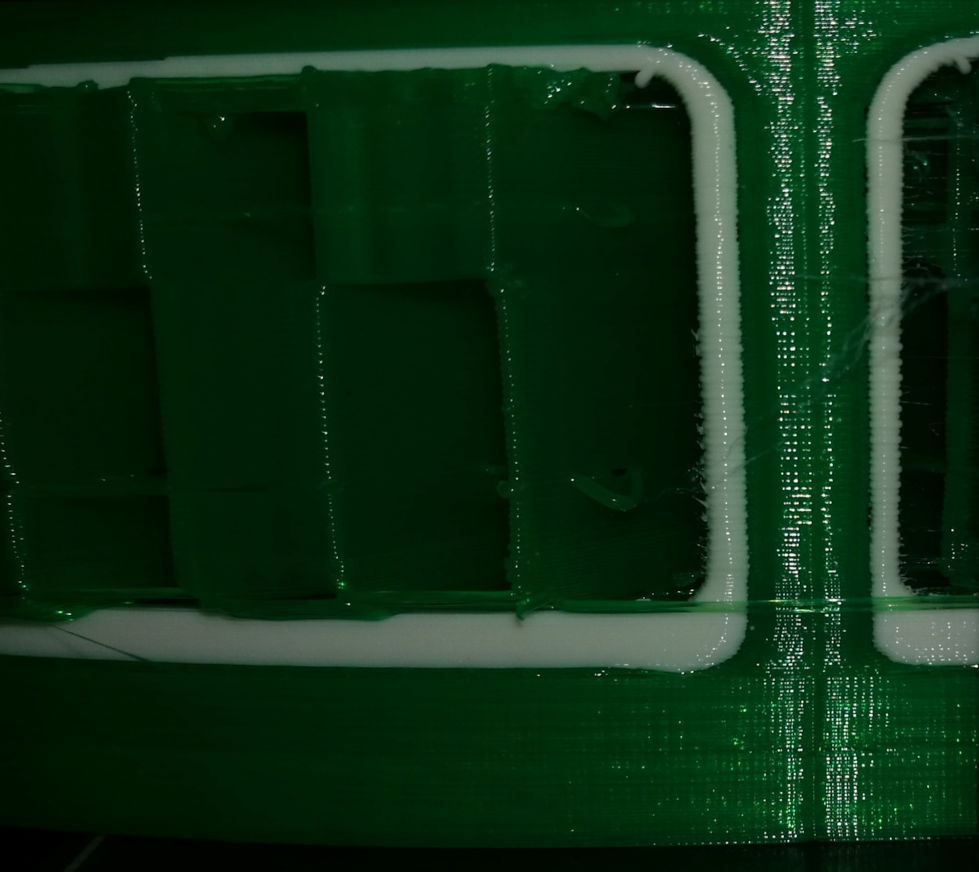

Hi there. I have recently gotten my Prusa i3 Multi Material. I started out with the presliced benchy. The layers seem to have some kind of ribbing/oozing ( see attachment). I sliced my own model with KISSlicer and I have the same problem. It's most notable with very tiny spot's, small print portions so to say.

My retraction/destring settings are 4mm at 50ms. The benchy was printed at 205 °C and the red/purple object at 200 °C. Are there any tweaks to make to solve this?

Any suggestions would be welcome 🙂

Re: Oozing/ribbing

It almost looks as though you have the wrong E-Steps value (like it's using single filament E-Steps)

Can you connect to the printer and issue an M503 to check?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Oozing/ribbing

It almost looks as though you have the wrong E-Steps value (like it's using single filament E-Steps)

Can you connect to the printer and issue an M503 to check?

Peter

I've added the screen of the M503 command

Re: Oozing/ribbing

OK, so it's not E-Steps. What about temperature. What filament are you using and what temp did you print at with single filament printer?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Oozing/ribbing

OK, so it's not E-Steps. What about temperature. What filament are you using and what temp did you print at with single filament printer?

Peter

Hi Peter. These are all PLA filaments from FormFutura except for the dark red which is from Filamentone. With the single filament printer I used to print those filaments at 200 °C.

To be honest I have barely used the light grey in the past as it had a rough surface even at a 0.10mm layerheight.

Re: Oozing/ribbing

Sorry, I am not being much help with this. Seem to be somewhat brain-dead this week...

It does look like over-extrusion. Did you measure the filament diameters? I tend to under-extrude with my setup, simply by setting the filament diameter to 1.8mm for PLA.

Do you want to upload a GCode file for me to look at and try? Zip up and drag/drop the zip onto a post.

Peter

I

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Oozing/ribbing

Sorry, I am not being much help with this. Seem to be somewhat brain-dead this week...

It does look like over-extrusion. Did you measure the filament diameters? I tend to under-extrude with my setup, simply by setting the filament diameter to 1.8mm for PLA.

Do you want to upload a GCode file for me to look at and try? Zip up and drag/drop the zip onto a post.

Peter

I

Your help is appreciated though. I actually just realised I've used your KISSlicer package from the KISSlicer forum. It sped up the wiping a lot. Not sure if I'm allowed to link that.

All the filament diameters are 1.75mm some deviate 0.01mm.

Re: Oozing/ribbing

Can't see anything obvious.

Can you leave it with me for a while; I will try printing the model.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Oozing/ribbing

Can't see anything obvious.

Can you leave it with me for a while; I will try printing the model.

Peter

It's a very time consuming model (10 hours), I don't want to waste your time and filaments.

The extruder motors have been slipping up as well, while I was trying to print a flat piece. Though most (95%) of the time they manage to keep up the pace. Could there be anything hardware related?

Re: Oozing/ribbing

The extruder motors have been slipping up as well, while I was trying to print a flat piece. Though most (95%) of the time they manage to keep up the pace. Could there be anything hardware related?

Yeah, that's obvious with the occasional missing layers in your pics. Maybe tension too tight? Unload one of the filaments. Is it heavily marked with the drive pulleys? Maybe you need slightly higher temps?

I did notice that you are extruding 0.46mm width - I usually use the same as the nozzle width, but that doesn't explain the Benchy.

Not a problem, I will try to start the print this evening - I have some spare filaments I won't use for anything else.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Oozing/ribbing

I've tuned the tension a little bit. It seems it was too tight. There were markings in the filament. But the clicking remains at higher speeds/flowrates. It is less then before though. I will try changing the temperature.

Well the benchy is the presliced two color version from Prusa. I did not do any slicing on that model.

I really appreciate the help 🙂

Wessel

Re: Oozing/ribbing

Just started the print.

Re benchy; that was what I attempted to imply in my previous post...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Oozing/ribbing

Just stopped the print. Here are a few comments:

1. I need to cap the tower printing speed to about 80% of the non-printing move speed (post processor fault).

2. You have set non-printing move speed to 60mm/s. This can go 2 to 3 times higher without problems.

3. First layer - I always print this at least 0.2mm. I find that 0.15mm first layers don't give sufficient "wriggle room".

4. I think your destring is too high. (Higher preload = lower destring required.).

Your comments on this picture please...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Oozing/ribbing

Just stopped the print. Here are a few comments:

1. I need to cap the tower printing speed to about 80% of the non-printing move speed (post processor fault).

2. You have set non-printing move speed to 60mm/s. This can go 2 to 3 times higher without problems.

3. First layer - I always print this at least 0.2mm. I find that 0.15mm first layers don't give sufficient "wriggle room".

4. I think your destring is too high. (Higher preload = lower destring required.).

IMG_20170906_091056.jpg

Your comments on this picture please...

Peter

Hi Peter. Thanks for your print, it's greatly appreciated 🙂

1. I could use the silent mode for this?

2. So I guess with non-printing move speed you mean the x,y travel speed in KISS? If it were to be higher there would be less time for the nozzle to ooze?

3. That means increasing the surface roughness of the bed. I guess I will make it 0.05mm then.

4. Ok so I have no experience with preload. Which values can you advise here?

So there's some ribbing in your picture as well. So I'm guessing my slicer settings arern't completely optimal. I see that with a lower layer height, at the upper part of the window, the ribbing is less. I will try a uniform layerheight of 0.13mm or 0.15mm. I might buy a 0.2mm nozzle, so I can print this with a 0.1mm layerheight. Are E3D V6 nozzles ok for this?

I'm guessing you don't have any skipped layers, so I have some hardware issues to fix.

I will try to increase the oversample resolution, so the shape will become more fluent. Though it might be some slight ringing as well, so I will try lowering the perimeter speed.

Again thanks for the help 🙂 You've helped me understand this process a lot better 🙂

Wessel

Re: Oozing/ribbing

1. I could use the silent mode for this?

2. So I guess with non-printing move speed you mean the x,y travel speed in KISS? If it were to be higher there would be less time for the nozzle to ooze?

3. That means increasing the surface roughness of the bed. I guess I will make it 0.05mm then.

4. Ok so I have no experience with preload. Which values can you advise here?

So there's some ribbing in your picture as well. So I'm guessing my slicer settings arern't completely optimal. I see that with a lower layer height, at the upper part of the window, the ribbing is less. I will try a uniform layerheight of 0.13mm or 0.15mm. I might buy a 0.2mm nozzle, so I can print this with a 0.1mm layerheight. Are E3D V6 nozzles ok for this?

I'm guessing you don't have any skipped layers, so I have some hardware issues to fix.

1. No silent mode will not help; I need to amend the post processor settings.

Basically, to do a "clean" filament change, I need to extrude an amount of filament at relatively high volumetric speed. This is too fast with lower layer heights. I will be releasing a new version of the post processor within the next week which will fix this and address a few other issues.

2. Yes, Trave Speed. This can be as high as 175mm/s and yes, it cam help with stringing.

3. No. KISS/Settings/Style/Layer Thickness 1st setting. Change this value to 0.2,

4. For regular PLA, I am currently using PreloadVE of 0.75, speed 25 and Destring 2, speed 50. But I am still fiddling with this. I have successfully printed parts with 0 destring and 0.75 preload.

Ribbing; yes every other layer. I think this may be caused by 2.5 loops. A 0.4mm nozzle will print happily at 75 micron layer height; you do not need a 0.2mm nozzle for that. The 75 microns is limited by the extruder (ESteps = 140); single filament printer is OK at 50 microns where the ESteps are higher (161.3). I still think that you should set extrusion width to 0.4...

Is there any chance you could upload the STL so I can try slicing with my parameters?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Oozing/ribbing

Ah so will the wipe tower be big enough at lower layer heights? Or do the dimensions of it need to increase?

I will increase travelspeed and see what the results are.

I will experiment with a destring of 2 then.

I will try 2 loops, it has been sufficient for me in the past.

I'm used to an extrusion width of 1 - 1,5 x nozzle diameter, so I guess 0,4mm couldn't hurt. I didn't know about the Esteps, lesson learned I guess.

The stl's files are zipped and attached. All the origins are correct, and I scale it to 40% of the original size in the slicer.

Wessel

Re: Oozing/ribbing

Ah so will the wipe tower be big enough at lower layer heights? Or do the dimensions of it need to increase?

The wipe tower size is automatic and depends on the amount of purge you need (use "PURGE=nn" - without quotes - in filament name or adjust in post-processor).

The size is calculated based on the number of changes per layer, the purge volume required and (as a result) the layer heights of each layer. Sparse purging is also carried out whenever required (due to fewer changes, lower purge volume and greater layer heights). It really is an "intelligent waste tower"... 😉

My concern is the speed of the purging may be too fast, so I will re-program the speed to be capped at 75 or 80% of travel speed. This is something I need to change in the post processor; nothing you can do about it. Sorry...

OK, I will slice and print the model - maybe only the first 25mm and without supports - to see if the ribbing remains.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Oozing/ribbing

Wow that really is an intelligent waste tower 😉 So basically any layer height would be compatible with this tower?

Well if travel speed becomes 175mm/s then purge speed becomes 140 mm/s. That sounds crazy xD I hope my neighbours can tolerate it..

Thanks for all the help still!

Wessel

Re: Oozing/ribbing

So basically any layer height would be compatible with this tower?

Yes, including variable height

Well if travel speed becomes 175mm/s then purge speed becomes 140 mm/s. That sounds crazy xD I hope my neighbours can tolerate it..

I did say capped to that speed. Currently the maximum purge speed of a 0.2mm layer is limited to 5400mm/min (90 mm/sec), but the problem is that at 75 micron layers, that increases to 240mm/sec - which is very wrong... Sorry. Obviously didn't work that one out when calculating. And yes, it this were not an open forum, there would be a few expletives written by now...

Just back from setting up an exhibition, so working on it now.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Oozing/ribbing

Wow that sounds interesting, it would increase the quality of multi material prints a lot.

Ah now I get your point about the speeds. I'm looking forward to the new release 🙂

Hope your exhibition was fun.