Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

I'm working on making an Y-splitter in aluminium as a whole. M5 threads in the top for each FESTO fittings and no metal tubes inside as it will be an integrated part of the block prepared in the right diameter from design. This will of course help the heat transfer. 3 not used quarters of the block helps cooling the last one in use. Then no alignment troubles from tubes not in the center. Not internal roughness and unevenness in the Y-splitters center due to use of printed 3D filament. How is this sounding? Now I have the whole model in SolidWorks ready for the last touches before thinking to have it manufactured on a 5-axis CNC milling machine

Please comment about the idea! 😛

Trust me, I'm an engineer 🙂 Always do your best. What you plant now, you will harvest later

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

It sounds good, but I have doubts concerning machineability. And costs...

A solution that doesn't leave 99% of the buyers in the rain would be preferable (i.e. off-the-shelf and printed parts).

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

If this works - It will of course be for sale for a reasonable price 🙂

One of my concerns are that if the filament blocks inside the new cylindrical hole (the replacement for the tube) then it can be hard to get it out. Today you are able to take it out and heat the tube and then take it out. That's not that easy with block of aluminium with not parts inside. 😐

Trust me, I'm an engineer 🙂 Always do your best. What you plant now, you will harvest later

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

If the tolerances are tight maybe you can get away with three layers screwed together?

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

If this works - It will of course be for sale for a reasonable price 🙂

One of my concerns are that if the filament blocks inside the new cylindrical hole (the replacement for the tube) then it can be hard to get it out. Today you are able to take it out and heat the tube and then take it out. That's not that easy with block of aluminium with not parts inside. 😐

i'm working in the same idea (bought a square bar of 30mm x 30 mm x 500 mm to cut & drill)... make a support to place under the drill, etc...

but didn't found a drill of 1.9mm larger than 40mm aprox (22 of them really drill, the rest cilindric)

do you know where to buy? do you know a system to mecanize that?

i think it's a good idea and i'm concerned with the same reason... but i think it's a good try to solve some problems...

in the end... it's a simillar system to diamond hotend

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

OK, I had to drill it (4.5 mm). It doesn't fit without drilling, at 4 mm it is still too tight to easily remove the PTFE. I think this would be a good solution, PTFE is self-lubricating and softer. So one could use a less aggressive unload strategy (the part where the filament end is moved around in the tube until it solidifies could be driven slower).

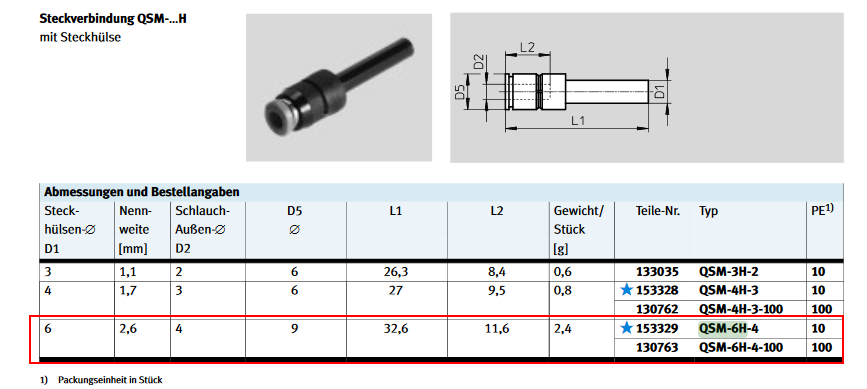

The part number for the straight part is IQSG 60H40, but I found Festo also makes them (QSM-6H-4).

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

More news!

It took me a long time to find the right settings for the PVA filament (that PVA is difficult to print!). But I can say to my own satisfaction, I printed ABS with PVA without deteriorating on quality. All the problems I had before the modification are completely gone, no hassle with grinding filament or anything like that. I can say out loud that my modifications worked for 100%.

I've been also reading a few comments and I'm going to interfere.

The reason I made these modifications on my own is because I didn't had a choice! I have no faith in Josef Prusa giving me a refund or a solution for the problems I faced with the MMU he sold. I have the tools/machine/knowledge and time to invest, so this was the most reliable and fastest way to get it working. But you guys have to understand, that this cost me more than 2 weeks of work to diagnose and repair!!! You have seen the pictures, machines, brass and special measuring tools! Who has that?!? I'm absolutely sure that Josef doens't have any tools I showed and I certainly don't expect you to have that!

With that in mind, these parts require a high tolerance in dimensions and finish! And my modifications are nothing more than that!!! Just new made parts with high tolerance! These are parts that JOSEF already delivered on his MMU, but JOSEF failed to get the high tolerance and finish that is required to get it working! Josef knows that this is required, there is enough proof that JOSEF himself shared on his own BLOG! (HERE and HERE)

So I would like to say to everybody with a MMU that doesn't work! Complain! Complain here, complain at support, complain on youtube, complain on Reddit! This is a lack of support and nothing more! The only way that this is going to be solved is by complaining!

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

So I would like to say to everybody with a MMU that doesn't work! Complain! Complain here, complain at support, complain on youtube, complain on Reddit! This is a lack of support and nothing more! The only way that this is going to be solved is by complaining!

I'm here to complain too... 😛

My printer is having the exact same problems yours have, bo.b. I am sitting here in front of it, trying to figure out what to do. Unfortunately, I dont have the equipment and machines you have... It would be nice to have Prusa chime in in this forum... I really dont have the time/energy/willingness to deal with this issue right now. I'd rather not have bought this "upgrade". I may simply remove the "upgrade" and go back to the plain MK2, which at least didn't have this issue...

I would really love is someone came up with replacement parts that worked. I would gladly pay...

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

If this works - It will of course be for sale for a reasonable price 🙂

I'd be interested... and I'd prefer a finished part. A (properly tolerated as we learned) drawing would be better than nothing, but I'd have to send it to one of the workshops I know (and this would not be cheap).

BTW as friction seems to be an issue - what about a nonstick coating like the Twinclad XT http://twincityplating.com/electroless-nickel-composite-plating-services.html like the Micro Swiss guys are using?

- Martin

- Martin

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

Bo can you show a list of changed part that you modified to get it to work.

I believe that Prusa should start producing such kits that all MMU customers should be offfered for free

Trust me, I'm an engineer 🙂 Always do your best. What you plant now, you will harvest later

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

Thank you Bo.b for sharing. I have a question about the PTFE tube. My filament always gets stuck between the PTFE and the heatbreak. It gets a blob there and I can not pull it back into the PTFE, where it should be formed to the 1.9 mm.

So did you change the PTFE tube to a brass tube with a proper diameter? Or did you only replace the stainless steel tubes in the upper part with brass?

Thank you and best regards

Michael

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

Hi bob.

I actually own a mk2s, planning to buy the mmu, but very cautious about this, because of all users complaining.

I only want to print pva support, keep monochrome prints.

but I dont want to loose the original mk2s quality of printing

I own a lathe, I could also build what you've done.

can you confirm that what you did fixed the problem ?

thanks your your answer

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

Thank you Bo.b for sharing. I have a question about the PTFE tube. My filament always gets stuck between the PTFE and the heatbreak. It gets a blob there and I can not pull it back into the PTFE, where it should be formed to the 1.9 mm.

So did you change the PTFE tube to a brass tube with a proper diameter? Or did you only replace the stainless steel tubes in the upper part with brass?

Thank you and best regards

Michael

Hello Micheal,

I need some more information about the problem. Does it happen when switching filament or only with retraction? Etc, etc. If you make a story of the problems then maybe I can be of some help. But if I pre guess I assume you have a wrong heatbreak with wrong tolerance.

Hi bob.

I actually own a mk2s, planning to buy the mmu, but very cautious about this, because of all users complaining.

I only want to print pva support, keep monochrome prints.

but I dont want to loose the original mk2s quality of printing

I own a lathe, I could also build what you've done.

can you confirm that what you did fixed the problem ?

thanks your your answer

In my last reply (page 3) I got this modification working with an ABS and PVA filament. So far I only read that people tried this filament combination and didn't get it working, so I assume I'm to only one who got it working on the MM. So yes, I can confirm that it fixed the problem.

But to fix the problems I had, I needed to replace more parts to get it working correctly, so there is no warranty you will have no problems when you lathe your own steel tubes.

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

I'm still working on improving the design of the MM. Let's say you get a really quick peak at the early stages of development, but with this it would be possible to manufacture in high numbers. But this design is absolutely not final!

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

Neat!

That metal inset of yours might actually do some cooling, since it's connected to the outside. Do you plan to press-fit it or design some clamping mechanism (I guess there's room for one screw)?

Also one I can't help but notice your metal inset looks very similar to the Festo+PTFE solution I suggested one page earlier. Do you think you could match the outside dimensions to that the plastic and milled parts could be interchanged? It would give more flexibility for experiments with different material, as well (maybe) as offer a usable solution to those without a lathe.

I could look up the dimensions of the Festo part if you think it might be feasible.

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

Thank you Bo.b for sharing. I have a question about the PTFE tube. My filament always gets stuck between the PTFE and the heatbreak. It gets a blob there and I can not pull it back into the PTFE, where it should be formed to the 1.9 mm.

So did you change the PTFE tube to a brass tube with a proper diameter? Or did you only replace the stainless steel tubes in the upper part with brass?

Thank you and best regards

Michael

Hello Micheal,

I need some more information about the problem. Does it happen when switching filament or only with retraction? Etc, etc. If you make a story of the problems then maybe I can be of some help. But if I pre guess I assume you have a wrong heatbreak with wrong tolerance.

Hi Bo.b

Since I have this problem, I just tried to print with one color. So it happens just by retraction. I tried to exchange the PTFE tube, but this did not help.

Right now I am thinking about making a new stainless steel heatbreak, with the former PTFE tube included in one part. So I dont have a transition and the filament can go through it very smoothly.

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

Hi Bo.b

Since I have this problem, I just tried to print with one color. So it happens just by retraction. I tried to exchange the PTFE tube, but this did not help.

Right now I am thinking about making a new stainless steel heatbreak, with the former PTFE tube included in one part. So I dont have a transition and the filament can go through it very smoothly.

I had similar problems and it helped to lower the retraction of the filament on a single filament print. Try 2.5mm or 3.0mm and do a single print again.

I don't know why this problem occurs, but I would like to know the filament you use and E value with the single print.

I recommend to replace the heatbreaker first, the PTFE is not the issue when everything is working like it should.

Neat!

That metal inset of yours might actually do some cooling, since it's connected to the outside. Do you plan to press-fit it or design some clamping mechanism (I guess there's room for one screw)?

Also one I can't help but notice your metal inset looks very similar to the Festo+PTFE solution I suggested one page earlier. Do you think you could match the outside dimensions to that the plastic and milled parts could be interchanged? It would give more flexibility for experiments with different material, as well (maybe) as offer a usable solution to those without a lathe.

I could look up the dimensions of the Festo part if you think it might be feasible.

I'm very limited to the dimensions and can't go bigger then this. But you can give me the dimensions of the Festo part, it's worth looking at.

Re: MMU unreliable, Prusa engineer are amateurs and Josef an fraud!

Hi Bob,

very nice - I am looking forward to see the results of this print.

Have you heard anything by now from PRUSA? Did they show any reaction?

BR, H