Re: Filament jammed

Your welcome, I also forgot to answer your other question, reloading grooved filament is fine. Just trim off any large burrs on the end. Most of the time it unloads with no burr.

Re: Filament jammed

Still working through jam issues myself. At one point I did print a 4 color gear (3hrs). But still getting a lot of jams in heatbreak/ptfe area. Acupuncture needle goes in nozzle fine. And increasing PLA temp to 220C helps. Have to increase to ABS temps when there is a jam.

Oddly though it appears that it happens more on Extruders 1 and 3. I did check the multiplexor, and pulled out PTFE tube (tube looks ok, fed filament in it, played around with an Allen key with it etc). I also tried some pulls at different temps.

It appears to work when it wants to. The extruder will skip steps occasionally (or constantly) and then it will jam during a print. I’ve also checked extruder gears, tension etc. All that appears fine. I just think it must be hitting some hard resistance when extruding out of the hotend.

So I guess next I will try another nozzle, and or loosen the block half a turn before reinserting PTFE as was suggested. I do have another piece of PTFE, so can try that as well.

Well I’m probably done for the night, but I’ll post once I finally get mine sorted! Really want to get on to printing.

Re: Filament jammed

Well I thought I had the jams fixed. was able to print a few marvins. but anything else jams and skips. My marvin's don't look perfect, not bad but not "prusa good"

So I did a nylon cold pull and took apart the hot end last night. I then pulled and re-seated the PTFE with the half turn on the heatbreak trick. replaced the nozzle with the one that shipped with the kit. I did a cold pull on that nozzle. then checked the filament path; It felt smooth.

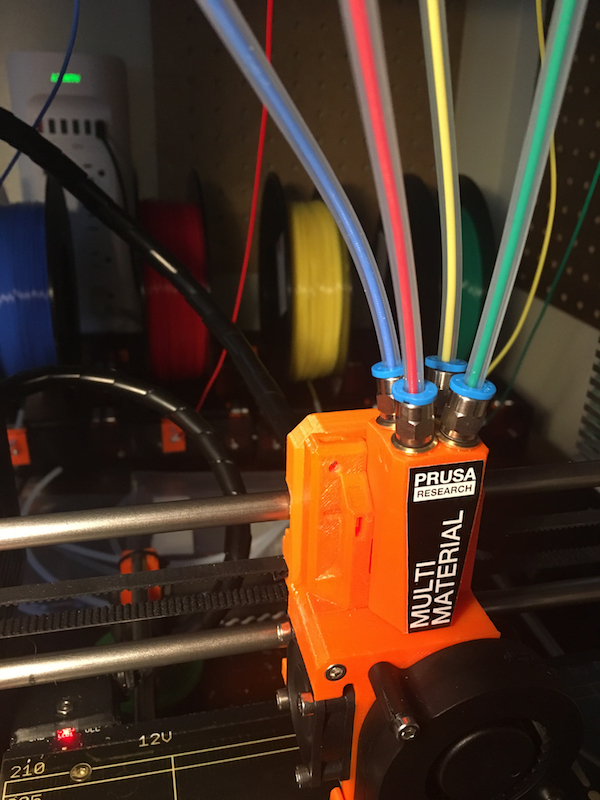

re-installed the multplexer. Checked the filament path down all 4 cooling tubes; they also felt smooth. I also checked all the set screws on the extruders and applied thread locker. then checked the idler tension set it at 4.5mm gap.

I also switched to high power mode and I'm still getting jams.

I bought some clear PTFE so I can see if maybe when the extruder does that back and forth motion in the cooling tube its going too far or something. I'm not really sure what else to do. Maybe also check the extruder calibration?

Re: Filament jammed

Not sure its gonna help me troubleshoot but it looks cool.

had to order 2 packs and yes I made sure to cut them the exact same length as the original.

https://www.amazon.com/gp/product/B06ZZCY88T/

Re: Filament jammed

Well tried just about everything. Even swapped nozzles for a Steel one for the heck of it. Still skipping steps and jamming 🙁

Almost ready to go back to a regular MK2 and give up on MM until they figure out whats going on. The only thing I can think of is quality issues with the new hotend.

Re: Filament jammed

If you unmount the multiplexer and push some filament through it, does it passe without force ?

Re: Filament jammed

The bottom of my ptfe liner did not have a taper or chamfer. I used a exacto knife to add a slight inner chamfer. So far its fixed all my jamming. i have only printed a few parts since, but already its a big difference.

Thanks Peter!

Re: Filament jammed

Same issue. After 4 sucesfull prints Extruder 1 jammed heatbreak. I can put fillament 40 mm into PTFE in heatbreak. 😕

Re: Filament jammed

Same issue. After 4 sucesfull prints Extruder 1 jammed heatbreak. I can put fillament 40 mm into PTFE in heatbreak. 😕

So you seem to have a blockage at the bottom of the PTFE tube. You probably need to remove the PTFE and check tha thte lower end is chamfered and tapered.

Good news is that it seems to be the case that the PTFE tube gets better the more you use it, and failures reduce over time...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…