Re: Jamming in the steel tubes

Never used Polysmooth, so I don't know how it will behave.

Those filament ends look OK though, however, I would still print a temperature tower; maybe go from 225 down to 190.

My guess would be that 200 to 205 will be fine.

It could be that this filament requires a slower unload strategy or it may also be that you need to re-seat or replace your PTFE tubing.

Can you measure the diameter of the filament ends with calipers and post the result?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Jamming in the steel tubes

Hi All

I got the same issues - probably a design issue

ISSUE: stuck filament (either in steel tube or the 4into1 MULTI filament part)

with a bit of experimentation

I must conclude that:

1. the cooling/retraction time it takes for filament 1 to exchange to 2 - will change the diameter of the filament so it get stuck in the steel tube

it either leaves a long tip that then bends or the lump as described on the pics

2. the inner holes of 4into1 MULTI part (which was 3d printed) is NOT CLEAR or smooth

I tried a bit of filament and even freshly cut can get a little stuck here

3. I have also noticed that the little tube can have issues allowing the filament to pass thru due to filament being slightly out of shape

POSSIBLE INTERIM SOLUTION

1. Carefully drill out the 4 holes in the MULTI nozzle with a 3mm drill bit - makes more smoother passage

2. carefully drill out the top of tube to the extruder with a 1.5 - 2.0 mm drill bit - makes slightly bigger entrance hole fo filament

3 if the retraction also and issue then try to loosen (0.5mm) the 4x inserts on the tubes into the extruder

4 Removed all steel tubes

Still testing

M

Re: Jamming in the steel tubes

Is the 1.89mm too big for the y-spliter ? because it is stuck there.

Quite possible:

That could mean your PTFE is over-sized. Or the cooling moves on unload are insufficient (but you cannot do anything about that within Slic3r).

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Jamming in the steel tubes

Another possibility is that there is a string from a previous unload in the tube as well.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Jamming in the steel tubes

Is it possible the Nozzle ? Because I changed it with MicroSwiss nozzle.

No, I don't think so.

When filament is unloaded, about 10mm remains in the melt zone; the nozzle is not much more than 10mm long (if that), so only filament within the heat break is unloaded.

The filament is withdrawn through the 1.85mm PTFE tubing to form the top and then into the cooling tubes (1.9mm) to cool; whilst cooling the filament is moved back and forth to prevent it from sticking while cooling.

You measured the filament end at 1.89mm, which is at the upper end of both the PTFE and cooling tube.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Jamming in the steel tubes

Sticking in the PTFE tubing can be caused by insufficient ramming before unloading; retractions before unload can cause melted plastic to solidify higher up in the heat break (2.1mm). The ram feeding before unload is supposed to counter this.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Jamming in the steel tubes

Thanks a lot Peter, they are important information for me. tomorrow will check the tube's Inner Diameter. So, the ideal size suppose to be 1.85mm ?

Re: Jamming in the steel tubes

So, the ideal size suppose to be 1.85mm ?

Drawing here: https://shop.prusa3d.com/forum/original-prusa-i3-mk2-multi-material-f26/blockage-troubleshooting--t4643-s110.html#p41606

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Jamming in the steel tubes

Hi Peter

Its just not working properly this multi

ij just tried flex - forget about it it even get jammed before it get to the extruder and I believe its design error

if you push two part filament into the same hole - one will get stuck

I might have to return it

m

Re: Jamming in the steel tubes

Hi Peter

Its just not working properly this multi

ij just tried flex - forget about it it even get jammed before it get to the extruder and I believe its design error

if you push two part filament into the same hole - one will get stuck

I might have to return it

m

After almost 12 months of use, I have to say that the MMU is working for me with almost total reliability for the models I want to print.

However, you do need to understand its limitations. You will never get it to work unless you learn what it is capable of and how to use all the different materials.

All this time has passed and I am still using PLA and occasionally PVA, but I am still learning with PVA which is currently only bringing about a 50% success rate. One of the issues with PVA is that each manufacturer's product is completely different and so far I have only tried 3 (eSun, PrimaSelect and Scaffold).

I am sure that one day I will try TPU, but I haven't had the need so far. That will cause me to scratch my head a bit but I will get it to print (bare in mind that I don't use Slic3r and have written a post-processor for KISS).

It really isn't a simple process of loading the filaments and then printing a model. There's a whole load more to it and the level of learning and complexity is not for everyone.

That coupled with the lack of PR support on this "Official Support Forum for Prusa Research" really doesn't help. It seems to me that the level of support here is very limited, with only a couple of beta-testers and a few users giving any advice.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Jamming in the steel tubes

thanks for your reply

seems to me that MULTI printing with prusa is limited to same material - just different colours

and also the software is quite problematic

tx

M

Re: Jamming in the steel tubes

seems to me that MULTI printing with prusa is limited to same material - just different colours

and also the software is quite problematic

I am sorry if I gave that impression; it was not intended. Printing with different materials is possible, it just takes longer to learn how to do it.

The firmware is stable; there are no real problems there. Software? Yes, as with all software there may be a few issues, but there are workarounds and faults are being worked on - it's mostly incorrect settings though. In any event, I use KISS; I don't have too many problems with that.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Jamming in the steel tubes

seems to me that MULTI printing with prusa is limited to same material - just different colours

and also the software is quite problematic

Your first statement is mostly correct. There have been scattered reports of people able to print with TPU but it really needs to be at least 95 hardness. Personally, I have not tried TPU yet.

Your second statement doesn't hold water. Slic3r for MM printing works quite well. I have been using it since the MM release and have found no real issues other than those with prints needing supports. For free software it is fantastic.

Re: Jamming in the steel tubes

MY EXACT ISSUES: slic3r

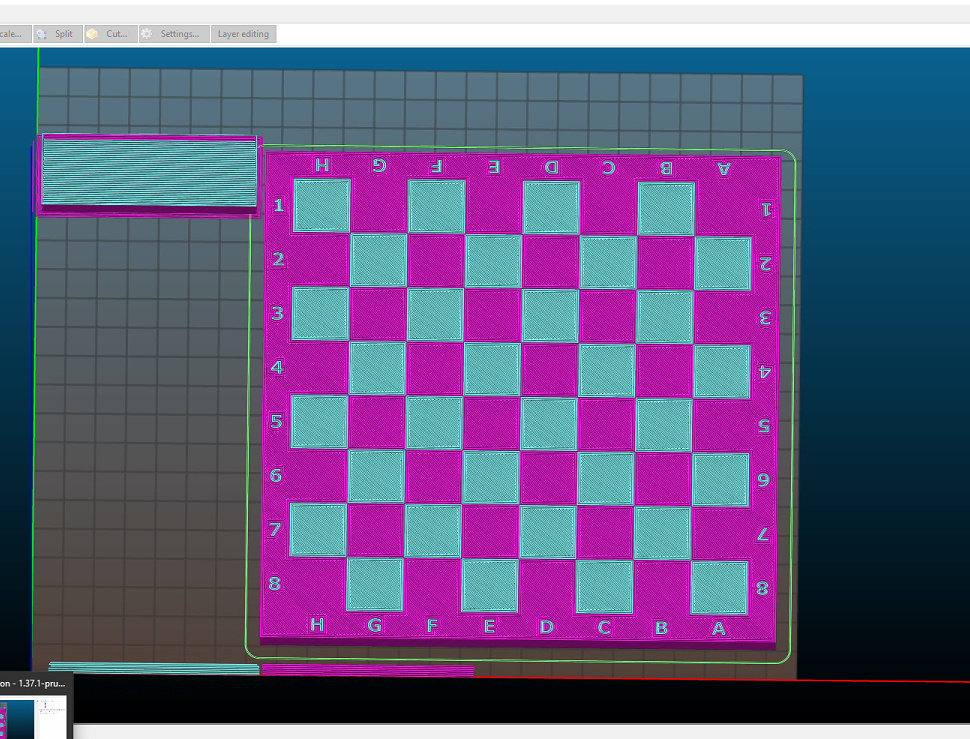

- slic3r won't work on Mac if you do a multi print where the parts are NOT on top of each other but horizontal!!!! say a checkerboard of some sorts

try it - it simply crashes

please can you try on a pc

Re: Jamming in the steel tubes

MY EXACT ISSUES: slic3r

- slic3r won't work on Mac if you do a multi print where the parts are NOT on top of each other but horizontal!!!! say a checkerboard of some sorts

Have you reported this fault on GitHub? If no, do so and provide the relevant STL files. It will get fixed.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Jamming in the steel tubes

Have you reported this fault on GitHub? If no, do so and provide the relevant STL files. It will get fixed.

Peter

I'm pretty sure it's the same issue that I stumbled upon a while ago and if so it's already reported and fixed, will be fixed in the next release: https://github.com/prusa3d/Slic3r/issues/535

Re: Jamming in the steel tubes

MY EXACT ISSUES: slic3r

- slic3r won't work on Mac if you do a multi print where the parts are NOT on top of each other but horizontal!!!! say a checkerboard of some sorts

try it - it simply crashes

please can you try on a pc

Hi Morten.

I recently posted some multi colour hearts. Done in slic3r... on a pc

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Jamming in the steel tubes

MY EXACT ISSUES: slic3r

- slic3r won't work on Mac if you do a multi print where the parts are NOT on top of each other but horizontal!!!! say a checkerboard of some sorts

try it - it simply crashes

please can you try on a pc

This must be a Mac issue. Works fine on my PC.