Re: Jamming in the steel tubes

Update: I continued to keep getting jamming, in the same scenario as described from this thread. - Even after loosening the screws on the bondtech mounts.

Fast forward to yesterday - where I ended up accidentally contracting a horrendous jam in the nozzle that - no matter what I did - I couldn't clear it. So, it was off to the races with my used 3d printer part box, and stealing a nozzle from an older hot end.

It was cheap far-east clone nozzle, so obviously I wasn't expecting anything... But miracles happen when you don't expect them. The used "Ebay Nozzle" is filling the billet quite nicely! - After multiple tests, the blob that used to form from before isn't present in any of them, nor have I had any retraction issues when the plastic goes back through the steel tube... SO FAR.

I'll keep an eye on it for sure, but it's looking promising as I'm writing this. Just throwing the info on this forum if others run into the same problem as described in the thread here. It may not fix the problem at all, but it appears to be working in my case. I'm guessing the way the inside of the nozzle is drilled out, it allowed for the formation of the blob on the original one, where as whatever magic is happening inside the cheap one - it's not allowed to form.

Hopefully this keeps going.

Same issue here... I'm getting the same blobs at the ends of the filaments, and jams no matter what. Dis the nozzle change did the trick??

Thanks!

Re: Jamming in the steel tubes

I'm having similar jams in the steel tubes but to be honest the filament does not even enter from the top. After measuring with a pair of calibers, it appears that some of my filaments are around 1.8 or 1.85 mm diameter so no surprise it is not working, but smaller/normal diameter filament works just fine. Maybe not your problem though.

Re: Jamming in the steel tubes

Try with lower temps. 200 to 205 seems to be right for most of my filaments.

Peter

Pete, do you mean increase the temp ? or lower it ?

Re: Jamming in the steel tubes

Try with lower temps. 200 to 205 seems to be right for most of my filaments.

Peter

Pete, do you mean increase the temp ? or lower it ?

He means lower. If the temperature is too high in the heat break, the filament is still soft, and can jam in the tubes. Lowering the temperature in the hotend also lowers the temperature in the heat break, which can prevent the jams if you are right on the edge. Cooler room temp or more extruder fan are other options.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Jamming in the steel tubes

Try with lower temps. 200 to 205 seems to be right for most of my filaments.

Peter

Pete, do you mean increase the temp ? or lower it ?

He means lower. If the temperature is too high in the heat break, the filament is still soft, and can jam in the tubes. Lowering the temperature in the hotend also lowers the temperature in the heat break, which can prevent the jams if you are right on the edge. Cooler room temp or more extruder fan are other options.

I've got it.

Now, I have a question: when you said "... can jam in the tubes", which tubes do you mean ? the Steel Tubes ? or the PTFE tubes ? I thought (correct me if I am wrong), the jam on each tube has different caused, and different solution.

Re: Jamming in the steel tubes

I was saying the steel tubes (Subject line of thread).

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Jamming in the steel tubes

I'm still in the learning curve you all already went thru.

The last thing i had was a jam in the steel tubes. Here is what i learned the last days:

- tension screws at the feeder are with 4mm-5mm distance unloaded much to strong, i am now at loaded 4.4mm

- the temperature of the Marvin sample gcode was to low for my filament 205, i am now at 215

- then i had a jam in the steel tube so i will lower it again...

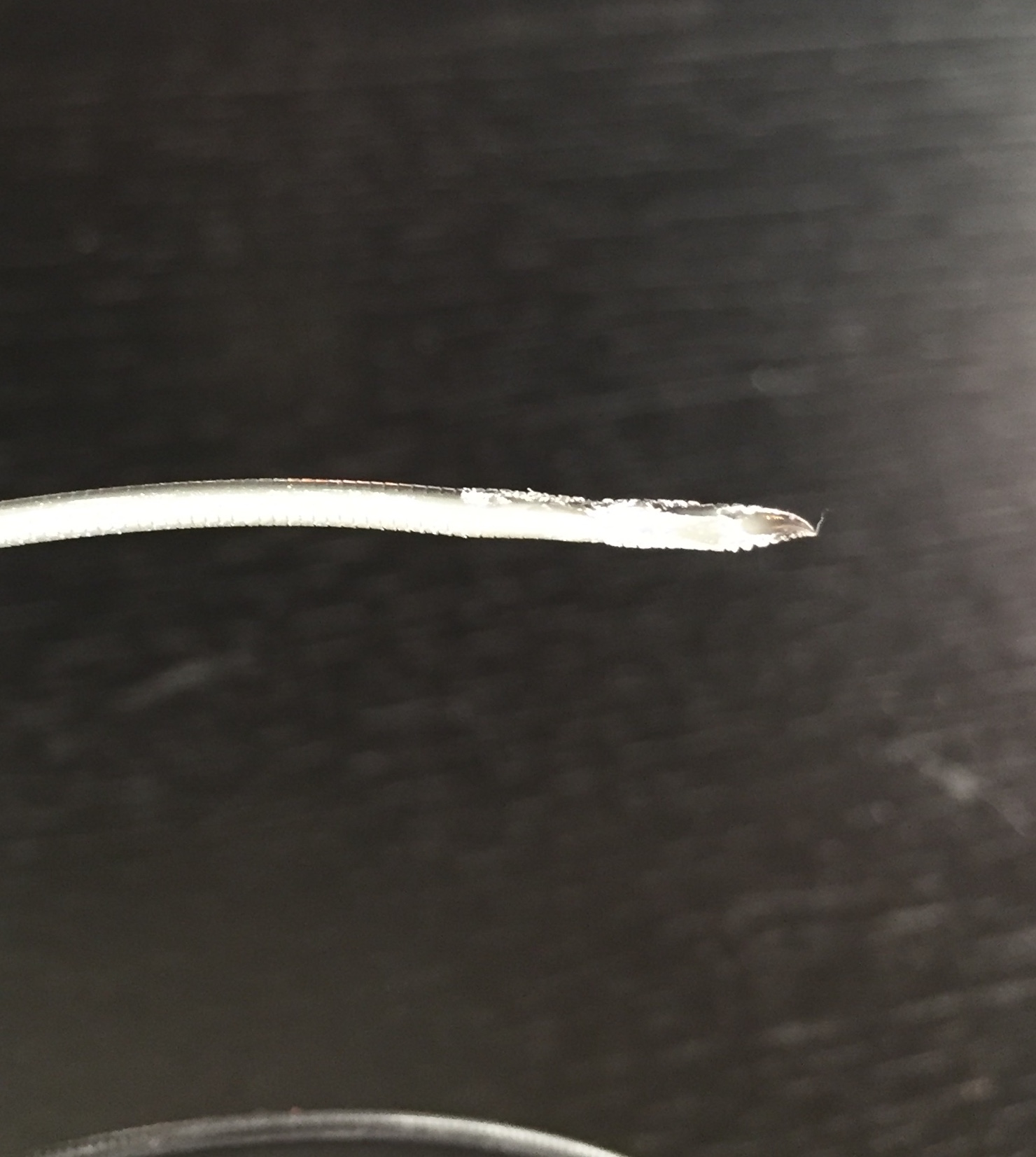

i put a picture in here with the filament damaged by skipped steps.

Can anyone post a filament image with a good "biting" from the feeder? How should it look like or looks eg when everything works?

last print stopped at 55% Marvin ;-(

Re: Jamming in the steel tubes

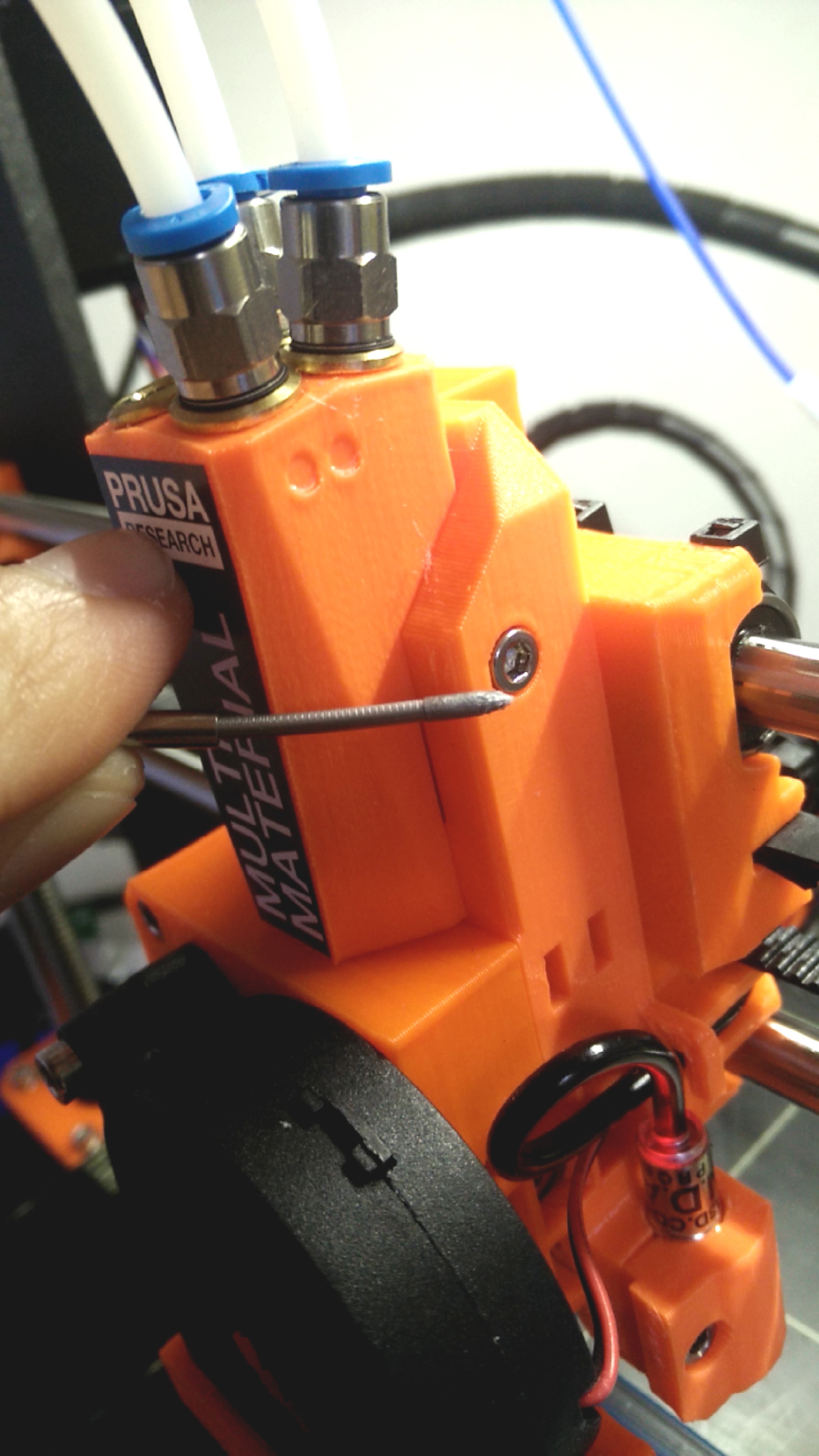

i know it might be a different thread but may be the cause of stucked / not sliding through filament is the same. I learned i am not the only one with stucked filament. Theory: lose/moving out of alignment steel tubes. Anyone else with this issue or know how to solve it? see pic:

Re: Jamming in the steel tubes

Apologies - I don't visit this forum often, and hadn't been able to read over this thread.

That being said, my MM setup is still going strong. So to answer the question if the nozzle change worked in my case, it absolutely did. Not sure about the other issues you guys are reporting, but maybe Pete can still continue to chime in as he has been.

Re: Jamming in the steel tubes

I would like to share my communication I had with the Prusa helpdesk with the exactly same problem of clogging with MM – and it still does... 😥

Hello,

I'm glad to see you - unlike other customers having the same problems - were brave enough to tweak the print settings and the printer configuration (springs tension), it's mostly all about the print settings indeed!

As you see you have results with higher temperatures but not great prints, that's fine, you may need to better adjust the print setitngs a bit more. The tension on the springs indeed can be adjusted too - fine! - just keep the spring length between 4 and 5 millimeters please.

- unfortunately the PLA starts to boil if printing with higher temp > 240°C, so even other print settings won´t help!

Which nozzle tips have you used so far?

- just the standard tips that came with my Prusa!

Any part of the hotend has been replaced?

- exchanged the complete hotend against the original one came with my Prusa i3 MK2S!

What is the filament material/BRAND have been printing from so far?

- Original Prusa silver, Tianse, Kaisertech, Sienoc, Fabbmatic, 3DW, Anycubic, Hatchbox, Herz

What are the two temperatures on the LCD when the printer is completely cool and what is the environment temperature? Even, have you noticed significant temperature fluctuations during the print?

- Environment temp is around 17,5°C

- Nozzle temp shows 22°C

- Bed temp shows 21°C

- You are right - I´ve noticed a higher fluctuation of the nozzle temp after the upgrade in a range up to +- 8°C !!

—> my China printer CR-10 is much more consistent according to the nozzle temp!

May you measure accurately the filament diameter in a 2-3 spots, few centimiters frome each other, then unwind for around 30-50cm and repeat for a few times?

- just vary in a range of approx. +- 0,03 - 0,04 mm

Do you think any of your filaments degraded?

- keep the filament in special boxes closed from environmental humidity with special desiccant inside!

- even brand new filament shows same behavior!

Have you tried each extruder motor and each filament you use in "MM single mode“?

- with the extruder came with the upgrade even MM single mode didn’t´t work! After exchanging to the original one, MM single mode is now working

on all extruders! Problem seems to move … now I have the clogging issue during the filament change because the last used filament gets stuck inside

the steel tube and not longer inside the PTFE!

- removing the steel tube when printing MM is unfortunately no solution!

Please mind the Multi Material configuration makes the printer much more sensible to the print settings compared to the standard MK2! Even there may be difference between "MM single mode" and multi filaments prints in the print settings.

- Understood your advice … but please also understand your fans and customers who trusted in PRUSA and love their MKS2 before the upgrade!

We bought a (tested) product (upgrade) and spent a lot of money but now we have just trouble and fail printings all the time and no real support from PRUSA like working print settings for Slic3r or even Simplify3D (which I favor)! I´m already very disappointed and starts to loose my faith in Josef and

his Team!

Regards

Michele Moramarco

Customer Support

Re: Jamming in the steel tubes

Some updates...

– temp fluctuations of the nozzle is solved after running the PID tuning 😛

– changed back to the MM nozzle with some ‚special properties’ 😥

> same problems came back means clogging behind the PTFE tube

- MM printing is still impossible by continuous clogging

> doesn’t matter if pre-sliced gcode or not!

- even printing with one Color is now a big adventure because if the Filament flow gets slow - e.g. when printing tiny details, the Filament gets stuck after the PTFE tube if performing the retraction.

- low retraction didn’t help and causes a lot of stringing

- big retraction (6-8 mm) is not working either due to less filament in the nozzle

- printing with high temperature for PLA >240C seems to help a little but creates stringing inside the PTFE tube during unloading the filament

- spring settings on the extruder at 5 mm as recommended seems to strong

> loosen the springs causes Filament slipping

Anybody who can support with some working slicer settings - also for Simplify3D (my favourite)

I already regret my decision to upgrade my beloved MK2S to MM... 😥

Re: Jamming in the steel tubes

I've got same Problem with Fillament jams PLA (PET works well) in the ptfe an steel tube. The Fillament Ends Looks like the pic above.

I do some Things to Change the behavour:

*reprintet new Extruder case, no changes

*a lot of Tension callibration, it's needed but no real Change with the blobs

*change the small pfte tube at the hotend, no Change

*polish the steel tube, no Change

*change retraction and zhop Settings, Little changes of the blob form but doesnt work

Finaly i adjusted the Fillament Extrusion Multiplier for PLA in the slicer Settings to 0.9 (must be fine adjusted later) but i ve four good prints of smaller objects, with different PLA

With less Multiplier the blob at the Fillament End shrinks and sqeeshes more in the length. Now ist going thru the ptfe and steel tube

If this is a solution for other People too, it's a good part for faq.

Re: Jamming in the steel tubes

Hi there,

here comes the next frustrated MM user 😥

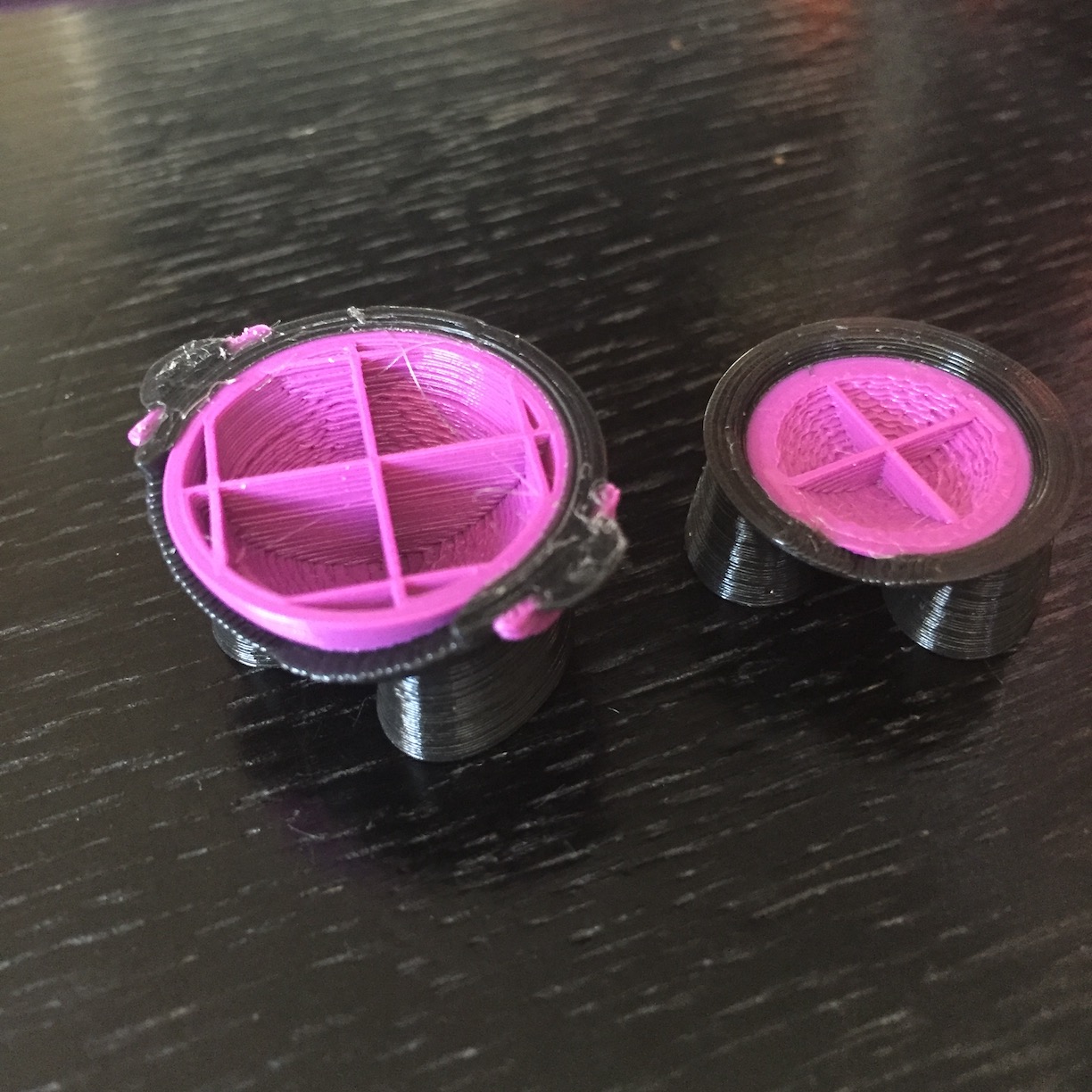

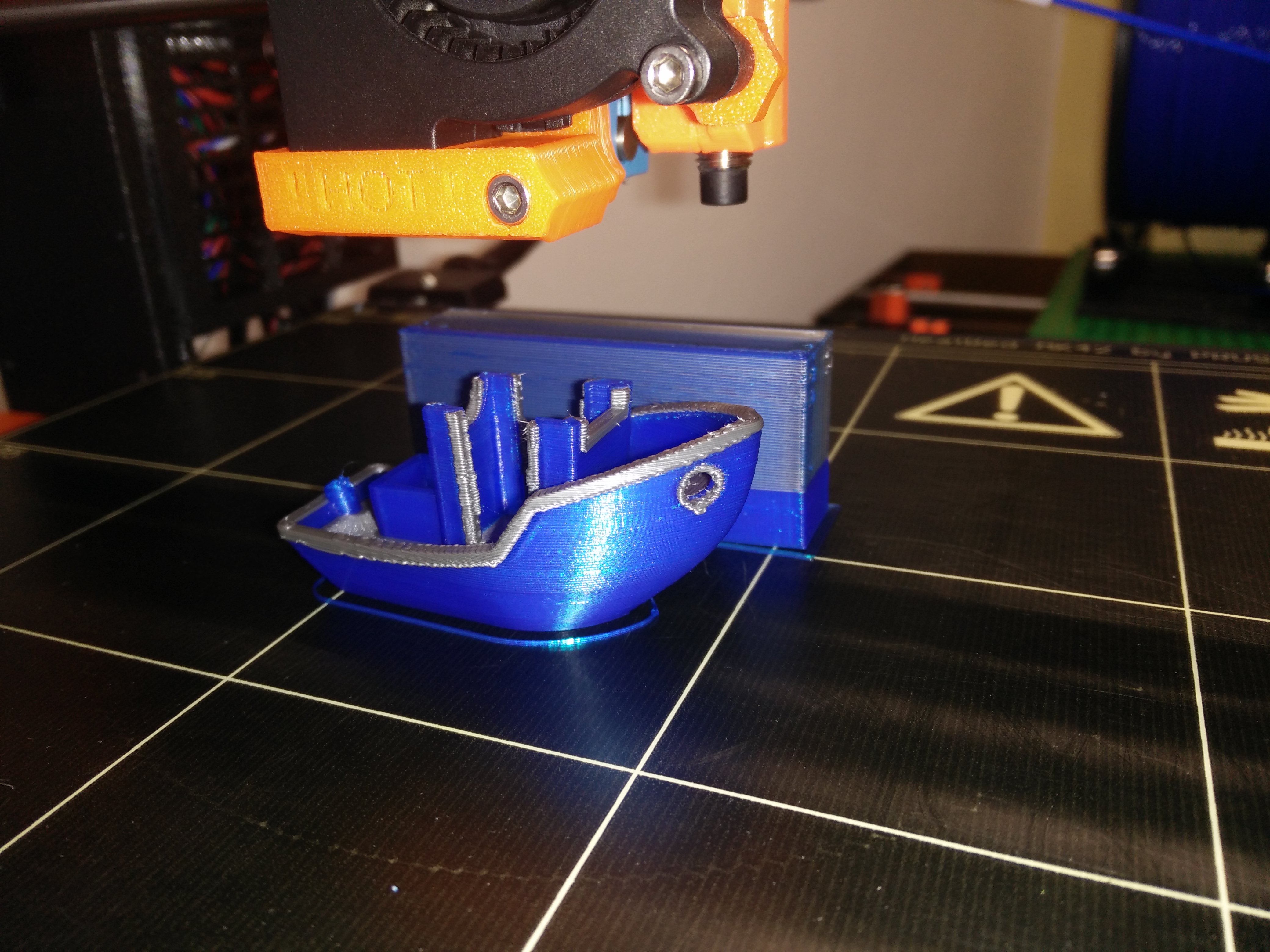

Doesn´t matter what i wanna print - none print comes successful to the end because of a jam. Here are some pictures from my last print.

I wanted to print the Benchy in two Color-Mode with the ready to print gcode (3DBenchy_2MM_PLA_5H.gcode) that comes with the latest Prusa Drivers. Used the Prusa Silver PLA that comes with the printer and a spool of Janbex PLA. The Bottom part was not a problem. But on the top there are more extruder changes needed... *bam* jam with the Silver Prusa PLA.

What should i do ? The GCode was ready to from Prusa Resarch itself.

Slice it again with a lower temp than 210 C° ?

The printer _was_ that good without the MMU...

Re: Jamming in the steel tubes

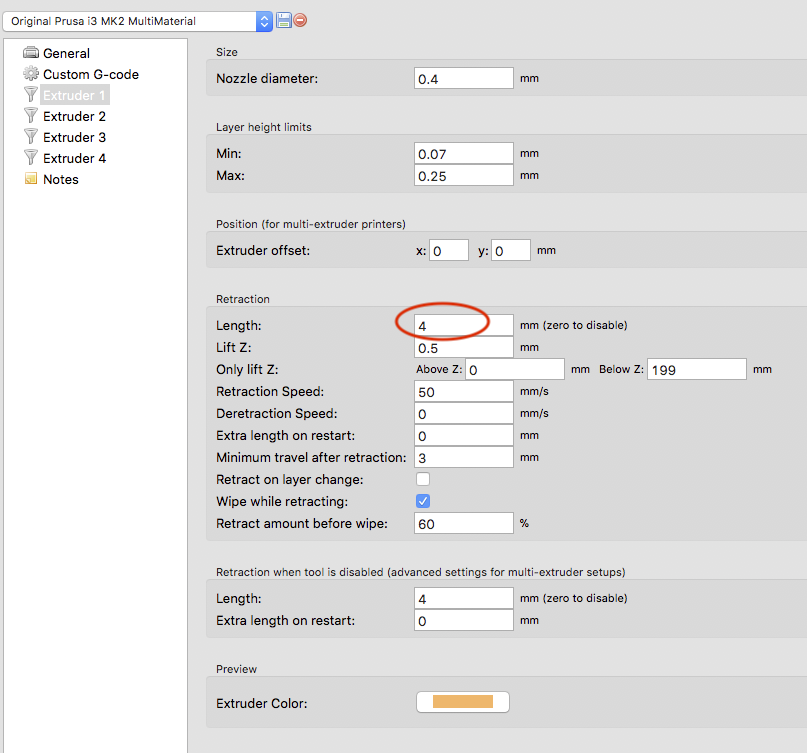

also consider reduced retraction... i am using 1.5mm retraction ---- default retraction seems to be 4mm which on my printer with MMU, was too much!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Jamming in the steel tubes

4mm is the standard retraction value when using Slic3r. If you reduce that you will probably encounter stringing. Bare in mind is is an extruder setting, so you may have to set it according to the material in each extruder.

If you can get linear advance set up, you can then reduce retraction values to around 2mm, maybe less.

Currently I am using between 1.5 and 2.5mm retraction depending on printer and material, but I am using the KISS "Preload" feature (similar principle to linear advance).

I think you should try reducing the temp by maybe 5 degrees and reduce retraction to 3.5 to see if that helps.

Wipes can also add to any stringing, so you may want to turn that off. However, turning on "Retract on Layer Change" can help reduce stringing.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Jamming in the steel tubes

Thanks @PJR for the confirmation and the info. It has been 2 weeks for me struggling to make it works.

I have read your post ( https://shop.prusa3d.com/forum/original-prusa-i3-mk2-multi-material-f26/blockage-troubleshooting--t4643.html

But, I still can't make it works, the best is; I only can print until 5%, then the filament stuck below the Steel tubes again and again.

When changing filament, the current filament blocks the hole on Y-Splitter. Seems like it stuck on the Printed part (Y-Splitter) instead of the steel tube, because when I took the filament Out and pushed to the steel tube, it went through smoothly, no issue at all. But, when I tried to push it back to the Y-spliter I can't, it stuck there.

Re: Jamming in the steel tubes

General indications are that you are printing too hot.

Print a temperature tower with each of the filaments you want to use to find the best single printing temp.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Jamming in the steel tubes

I am sorry my fault. I think that is not the best picture I posted. It was last week result, here the latest. Does it still too hot ? All four filaments are PolyMaker PolySmooth which recommended temperature is between 210-230. It was 210, should I lower it to 205 ?

General indications are that you are printing too hot.

Print a temperature tower with each of the filaments you want to use to find the best single printing temp.

Peter