Re: Blockage troubleshooting.

Some extra info:

I started a new print tonight.

Filament was "fresh" with a 45 degree cut. After some time the extruder starts skipping.

I disassembled the MMX.

By hand I can "extrude" by pushing the filament in the hotend (through the special PTFE tube. Just with some force.

I disassembled the PTFE tube from the extruder and assembled the MMX and I can "extrude" by pushing the filament through the PTFE tube, through the MMX and the hotend. It will take some more force (PTFE tube, cooling tube), so I think the pathway of the filament is oke.

Could it be the retraction is to long? I played with these settings before but no luck.

Hope somebody has answers for me.

Frans

Frans Krau

Europe, Holland, Apeldoorn

Re: Blockage troubleshooting.

Could it be the retraction is to long? I played with these settings before but no luck.

Hope somebody has answers for me.

Frans

Sounds like a PTFE shaping issue; check the lower end to make sure it is tapered and chamfered and then install it according to the instructions earlier in this thread.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Peter,

thanks for your reaction. The PTFE tube is tapered and chamfered and has the exact length. I will make a new one.

With the Original Prusa PTFE tube I had the same problem.

Can you explain to me (so I can follow your thoughts 🙄 ) why this is the cause of the blockage?

Has it to do with the retraction?

Frans

Frans Krau

Europe, Holland, Apeldoorn

Re: Blockage troubleshooting.

Frans

You cannot just push the PTFE into place and expect it to work.

Please install it as I described earlier.

Regarding retraction; that can be a major cause of blockages if your hardware is not right.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Hello,

I must admit that after reading this forum, I was scared to do the upgrade but I did it. The first print didn't go very well and I had a blob stuck in the multiplexer which was mostly my fault as I used the move axis to extrude manually some filament as it was somehow stuck somewhere and after that filament was not retracted enough in the end which caused a blob later. So far, I haven't had any big issues.

From my little experience, I am tempted to say that there's somehow minor issues which may cause trouble during assembly and early uses.

- during the mounting of the multiplexer, try to have the cooling tubes well aligned with the festo fittings.

- Before the very first MM print, make sure both firmware and software are updated/installed for MM.

- demo gcode file for MK2S caused me some trouble until I wipe the sdcard and put MM demo files. The printer does not behave exactly as before therefore it is safer to assume that the gcode that used to work on single filament printer will not work as expected unless you slice it for "Single mode MM".

- try to fix the spool holders securely as for half empty spool, sometimes the extruder drag the holder because the filament does not flow smoothly through the ptfe tubes of the holder.

It won't solve mechanical issues but it may help some of you.

Lionel

Re: Blockage troubleshooting.

Big thanks Peter!!

This weekend I will make and install the new PTFE tube as described in your post.

I have printed the instructions so I can lay the instructions near my workbench, so I won't skip a step 😀

Wish me luck

Frans

Frans Krau

Europe, Holland, Apeldoorn

Re: Blockage troubleshooting.

Wish me luck

Nah, you don't need luck. Just a little bit of patience and care 😉

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

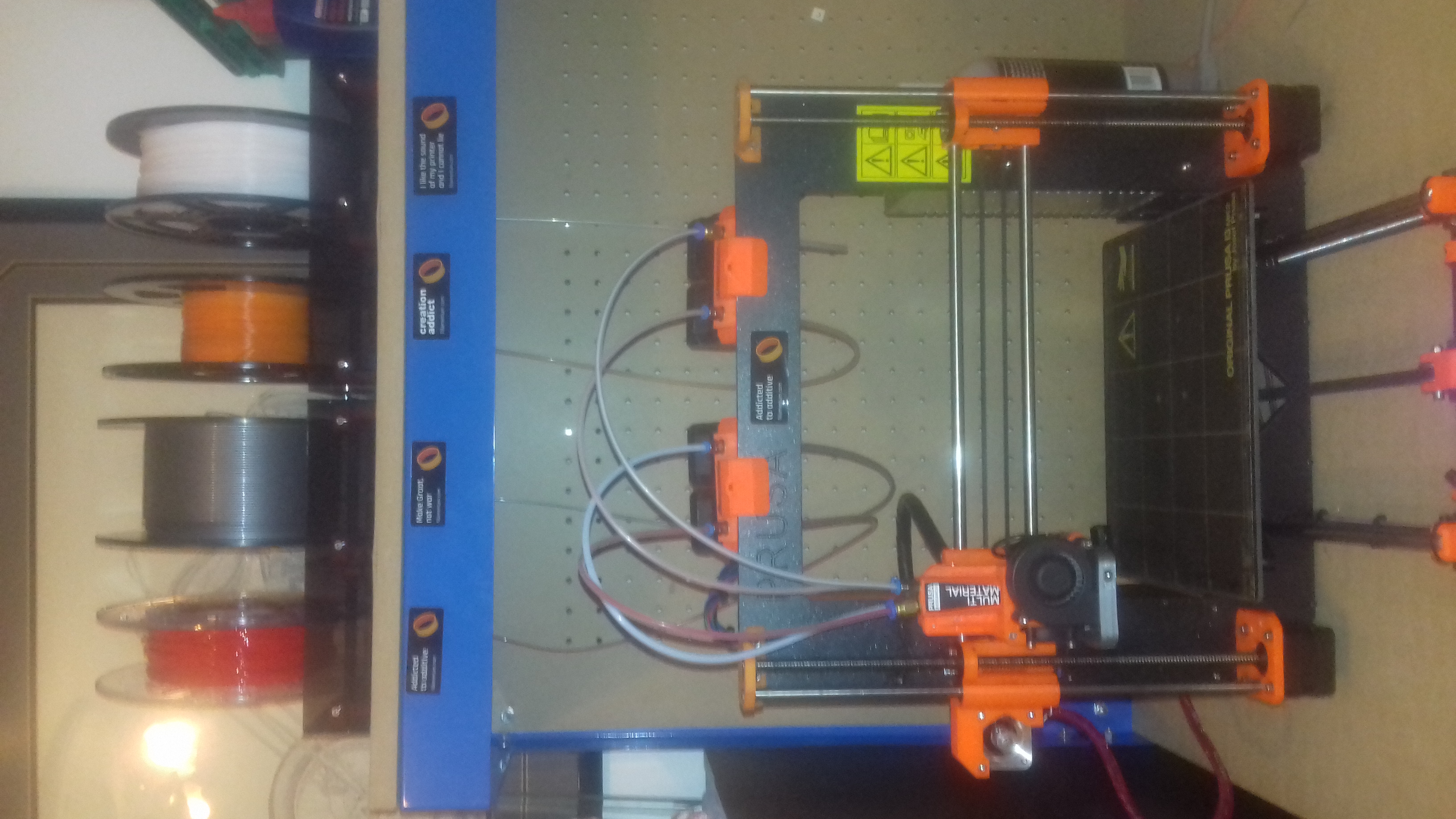

I use a piece of PTFE tube between the input side of the drive motor and the spool, and this stopped the filament dragging the spool holder around

I didn't physically join it to the ptfe tube on the spool holder, and now when the filament is retracted at colour / material change, the filament doesn't spill off the sides of nearly full rolls, which reduces the chance of snagging later!

as you can see on the pictures above

regards Joan

Did I mention that I hate cellphones... those pictures were 90 degrees rotated on my cellphone and laptop screen

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Blockage troubleshooting.

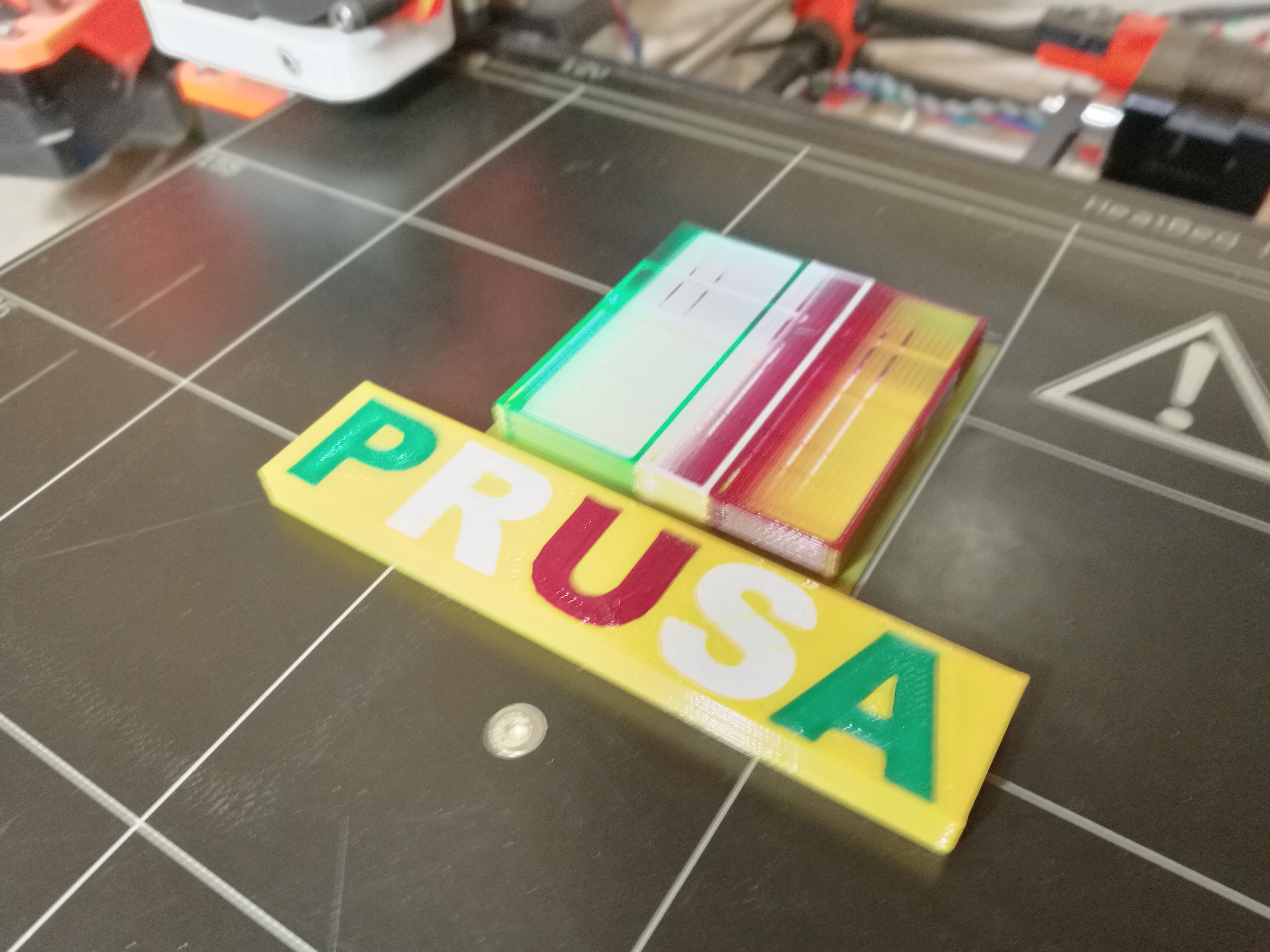

Peter, How much time does your four color "Prusa" emblem take to print ? Thanks !

Re: Blockage troubleshooting.

Peter, How much time does your four color "Prusa" emblem take to print ? Thanks !

I really cannot remember. Will reslice and print and let you know.

Peter

EDIT: It is about 3 hours, but the time will depend on the colours used (the purge distance required). I resliced and processed the model with opaque in extruders 1 and 4 (Green and Red/Purple), translucent in E2 (Yellow) and Transparent (white) in E3, with purges of 30, 60, 80 and 30mm (E1 to E4).

The attached file is the latest with the purges mentioned above.

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Finished in 2h 1m 26s.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Hello Forum (and Peter 😀 )

I took apart the heating system as discribed bij Peter. Precise job, but it worked well.

What I noticed is that the nozzle is now "straight" connected to the heatblock. The original distance was 0.8 mm. So the nozzle was not as near as possible to the heatblock. That cound mean that the nozzle is now better heated bij the heat block

I printed the calibration lines form Prusa MM, and that printed fine.

Then I printed the square for Z calibration and that went fine to.

I will inform this forum about my bumpy path with the MM

Frans

Frans Krau

Europe, Holland, Apeldoorn

Re: Blockage troubleshooting.

Hi Franz

There should be a very small gap between the nozzle flange and the heater block, but the smaller the gap the better. If there is no gap at all, the top of the nozzle will not make a good seal with the bottom of the heat break and you may get filament leaking from the top of the heat block (where the heat break enters the heat block).

Just keep an eye on that part.

I think though that you are now happy with the MMU (based on your test prints so far)?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Hi Peter,

I have now a print running. No skipping of the gears until now.

Until now I am happy with the Prusa "beast to tame".

About the nozzle: I did fully screw in the nozzle and then a quarter of a turn back. When thigtening the nozzle, I coud only turn it 1/8 of a turn.

I will keep this forum up to date with my experience

Happy printing now

Frans

Frans Krau

Europe, Holland, Apeldoorn

Re: Blockage troubleshooting.

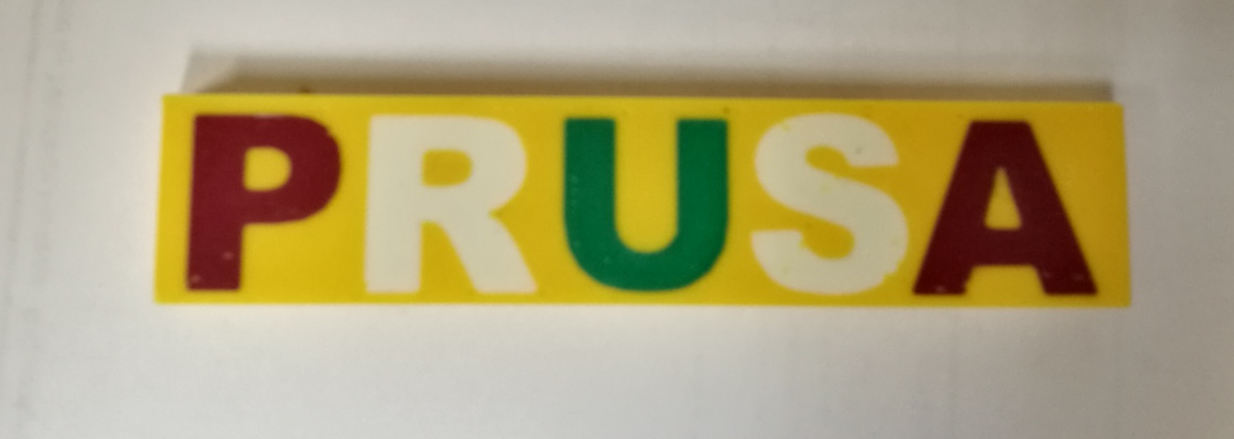

I just printed your latest " Prusa", and I'll try to attach a picture as I wonder if it printed right. The "U" is probably 2-3 mm from being flush with the top. In your picture on the previous page it looks like it is. If this isn't right I'll take apart e4 and see whats up. Thanks !

Re: Blockage troubleshooting.

I just printed your latest " Prusa", and I'll try to attach a picture as I wonder if it printed right. The "U" is probably 2-3 mm from being flush with the top. In your picture on the previous page it looks like it is. If this isn't right I'll take apart e4 and see whats up. Thanks !

Yes, you had a blockage. Should be flush top and bottom.

What filaments are you using?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Dear Forum,

the joy was for a short time.

The second print (the same as the first) didn't end well because of blockage. The gears of the extruder clicked again.

After a did the job of adjusting the heatsink, nozzle, etc, as described by Peter in the beginning of this thread I run out of solutions now.

Why is there so much drag/resistance in the pathway of the filament, that the gears starts slipping?

And why is it not all the time?

Should I contact Prusa?

Frans

Frans Krau

Europe, Holland, Apeldoorn

Re: Blockage troubleshooting.

Peter, here's an update on my Prusa logo print where the "U" didn't finish. i didn't have a blockage, the filament on E4 had been retracted about 75 mm so it was no longer being used. I really think I have a glitch in my firmware as other weird things are happening too. I'm going to post a separate post on these. So I changed to a different roll on E4, a roll of eSun PLA+. It printed about 15 minutes, then this filament jammed in the PTFE tube going to the hot end. It jammed so bad I thought I was going to have to get a new tube. But I got it out, and it looked like it was printing way to hot, had a long string at the tip. So I took this roll off and loaded a different filament, another eSun in a different color, then it finished successfully. HMMM........

BTW, is it supposed to change extruders being used during the print ? 1 + 4 swapped midway. Just wondering because of some other weird things going on.

Thanks ! The adventure continues.......

Re: Blockage troubleshooting.

Peter, here's an update on my Prusa logo print where the "U" didn't finish. i didn't have a blockage, the filament on E4 had been retracted about 75 mm so it was no longer being used

That was a blockage. It goes like this (there are a few scenarios)...

The filament in use before E4 fails to unload properly - maybe a string or possibly a full unload failure - and either a string or the filament remains in the lower end of the MUX. Or E4 on the previous unload pulls a string back into the SS cooling tube and jams there.

So when E4 tries to load, it can't and the extruder skips. However, it can unload; the unload takes the filament out by around 85mm and you end up with what you see.

Another likely scenario is that the filament has an oversized blob - this can happen several times on a single spool. That prevents the filament loading into the cooling tube and causes skipping on load, but it can still unload as above.

The filament blob happens during manufacture - I think it is when the manufacturer is changing the large spool which receives the extruded filament due to lack of tension on the extrusion.

It has happened to me with 3 spools received from PR and 4 from a local manufacturer.

Peter

BTW, I have not had much luck with eSun - the diameter control on the rolls I tried were very poor and caused blockages.

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

BTW, is it supposed to change extruders being used during the print ? 1 + 4 swapped midway. Just wondering because of some other weird things going on.

Yes

Bottom:

Top:

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…