Re: Blockage troubleshooting.

Thank you for this thread, it helped me a lot with troubleshooting my blockage problems. They were very sporadic and typically after long runs, I've got a blockage after 95% of the Chimera was printed... 😥 And what's worse, after that I couldn't even successfully print a calibration layer without blockage.

After checking the Extruder, hotend PTFE tubes and everything I gave up and blamed the filament. Then I scrolled through this thread and suddenly it dawned on me: it was not the long runs causing the blockage per se but the fact that I was printing pre-sliced gcode delivered with the printer, and Prusa likes to print PLA with 215 but I print my PLA usually at 190 to 200max, 205 with some. Especially the PrimaValue filament does not like being printed hot at all, this was true for the Wanhao it came delivered with as well as the MK2S MMU and NonMMU version.

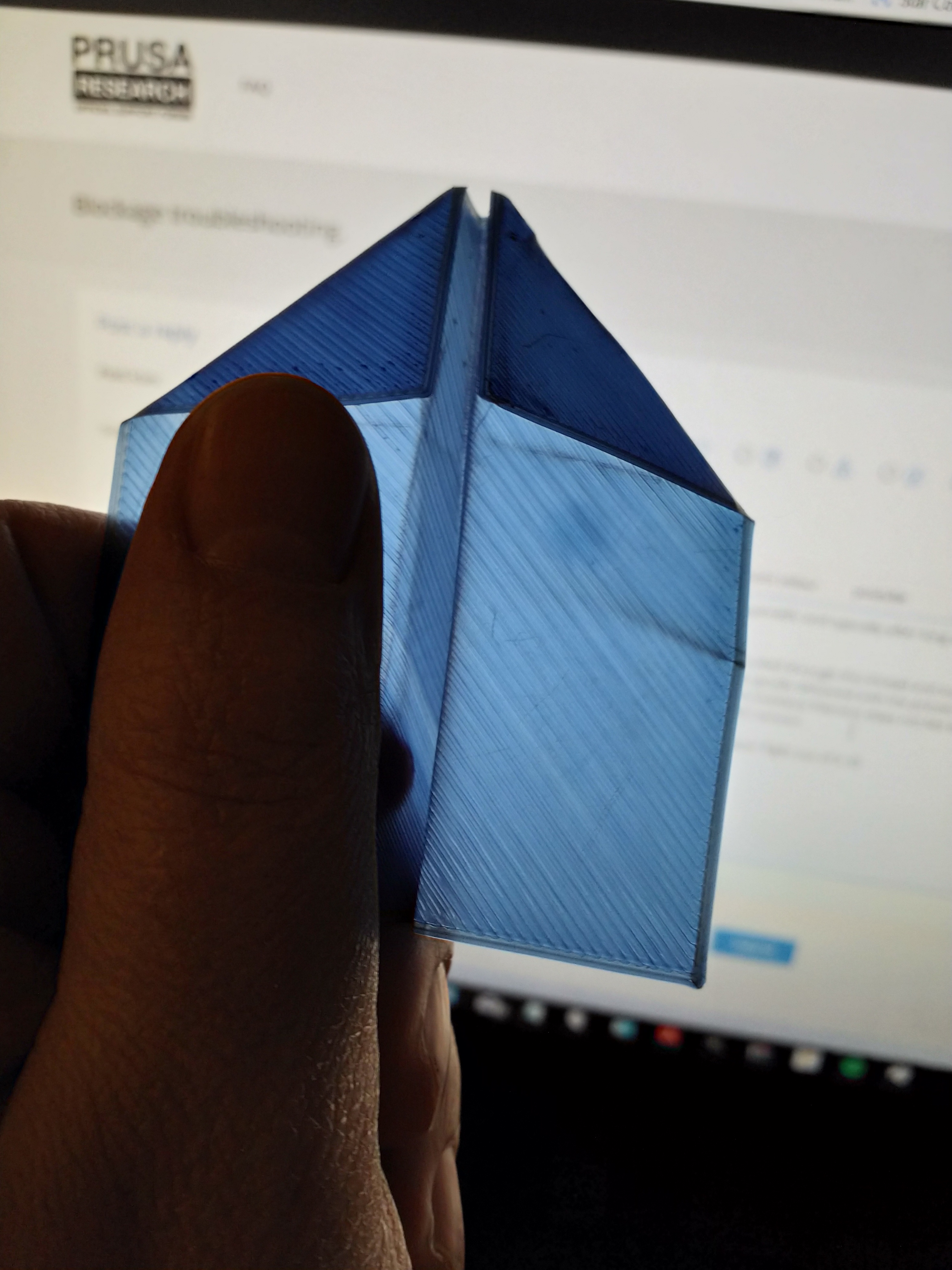

So I've dialed down the temperature and the calibration rectangle for Live-Z prints very nicely, just made a paper flight out of it 😀

Re: Blockage troubleshooting.

Hi all,

I disassembled and reseated my PTFE according to Peter's instructions, but to no avail. A systematic test yesterday with temps 215/210/205, retraction length 4/3/2 and retraction speeds 50/35/25 completely failed (I only changed one setting at a time and slowly worked my way down). With 205/2/25 I get quite catastrophic stringing.

I unrolled my spools several meters and checked the filament thickness before print attempts, all fine (I'd say excellent, variations were tiny). The insides of the hotend and heatbreak when disassembled looked spotless, the tapered part of the PTFE sits flush. I also rechecked all Festos for movement, as well as the Bondtechs. Everything grips nicely, no wobbling. I don't have any issues with the metal tubes as well, they are perfectly center with almost no resistance. I'll try Peter's PRUSA logo gcode tonight, if I cannot print that my conclusion is that something must wrong with my hotend. I'm really at a loss here, the only thing I haven't checked so far is the thermistor (will try to find one at work to use as reference).

Maybe someone from Prusa could comment if they have any insight on these weird problems? Could this be a production tolerance issue?

Thanks everyone for their help so far, this thread is great.

Re: Blockage troubleshooting.

Hi all,

I disassembled and reseated my PTFE according to Peter's instructions, but to no avail. A systematic test yesterday with temps 215/210/205, retraction length 4/3/2 and retraction speeds 50/35/25 completely failed (I only changed one setting at a time and slowly worked my way down). With 205/2/25 I get quite catastrophic stringing.

I unrolled my spools several meters and checked the filament thickness before print attempts, all fine (I'd say excellent, variations were tiny). The insides of the hotend and heatbreak when disassembled looked spotless, the tapered part of the PTFE sits flush. I also rechecked all Festos for movement, as well as the Bondtechs. Everything grips nicely, no wobbling. I don't have any issues with the metal tubes as well, they are perfectly center with almost no resistance. I'll try Peter's PRUSA logo gcode tonight, if I cannot print that my conclusion is that something must wrong with my hotend. I'm really at a loss here, the only thing I haven't checked so far is the thermistor (will try to find one at work to use as reference).

Maybe someone from Prusa could comment if they have any insight on these weird problems? Could this be a production tolerance issue?

Thanks everyone for their help so far, this thread is great.

Nils

Of course there is a possibility of you having something wrong with the hardware, but I have been assured that the quality control has been significantly improved since the MMU started shipping (when nobody really knew what to check...).

There is also a possibility that your thermistor is not so accurate (due to tolerance); so I would suggest that you print a temperature tower for each of the filaments/extruders individually that you are currently using. I think I posted the G-code for one early on in this thread.

Simply edit the G-code and change all instances of T0 to T1, T2 and T3 to change it for each extruder.

Peter

EDIT: TempTest G-code is in the first post of this thread. The file contains 2 instances of "T0" which both need to be changed to switch extruders.

The G-code prints a 20mm cube starting at 215 degrees and ending at 175 degrees.

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

**Sigh**

Thanks that's actually what I should've done yesterday. So spoiled by using foolproof printers that don't ever require temp towers 🙂

I'll try that and measure the actual hotend temp as well asap.

Re: Blockage troubleshooting.

if I cannot print that my conclusion is that something must wrong with my hotend.

You might be on the right track here. After I thought I fixed all problems I've printed a model which was quite fine and then another one, when the same problems you are describing began. Clack clack clack, nothing goes through anymore and I have to abort the print. I then took apart the multiplexer and two of the extruders, one bowden gear was not exactly spot on and I thought I've found the culprit. But no matter what I tried, reducing retract, different temp settings and so on, after a short while the Extruder would begin to slip on the filament. Sometimes it would print fine after a while but most times it would stop extruding.

So I had to take apart the multiplexer again and thought what the heck, I can as well just swap the noozle for my MicroSwiss Steel 0.4 noozle. Recalibrated everything (after the head slammed into the bed because of too high PINDA 🙁 ) and made a test print to fine tune Z. And then another one, and now I'm printing a 100% infill model - not a single stutter, no clacking, nothing, I still can't believe it - 30 mins after 5-6 failed prints the machine prints like a dream with the same spool of filament I used before.

I don't think that the problem is gone because steel is better but simply because this noozle is cleaner. After all those failed test prints, blockages, extruder problems and so on I must have blocked the noozle for good a bit and the bowden drive is too indirect to simply push stuff through by force.

Which led me to the most important realization to what the root cause of all my blockage problem was: Unloading after printing is NOT optional!

Honestly, I never bothered with the Non-MMU version or any other printers to unload after a print if I intended to print the next day or so. But I know from vivid memory that I had at least one blockage on the second print after a previously succesful print just one hour later. I then tried to unload the filament, which didn't work either and once I've removed the Festo I noticed a blob on the filament, preventing it to be pulled through the metal tube.

So when it says "Unload all used" after a print - do it, don't skip this step. I now understand that it's there for an important reason, not just convenience.

Does this sound about right Peter? I'm asking because for the past few days I've several times thought that I've "nailed it" only to be disappointed by another failure, but I truly hope that now with the clean noozle and always unloading the blockages shouldn't occur so frequently anymore, if at all.

Re: Blockage troubleshooting.

Don't think that's it. I always did the unload and before reassembly I cleared the nozzle using a heatgun and a fine needle. Total mileage of that nozzle is maybe 1/3 of a spool, only PLA. It could still be poorly manufactured, so maybe I'll swap it for good measure, but first things first.

Re: Blockage troubleshooting.

...and measure the actual hotend temp as well asap.

Not easy to do; IR thermometers don't work very well on reflective surfaces.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Does this sound about right Peter? I'm asking because for the past few days I've several times thought that I've "nailed it" only to be disappointed by another failure, but I truly hope that now with the clean noozle and always unloading the blockages shouldn't occur so frequently anymore, if at all.

Yeah, sort of.

Filament should be unloaded to the cooling tubes after a print, but you will see from one of yesterday's posts that the final unload G-code is not quite correct in Slic3r.

When you do get a clean final unload (and that is to the cooling tubes only), there is no problem printing straight from there - I do this all the time.

Regarding the nozzle. I totally agree that changing the nozzle is a good idea. I no longer use "expensive" nozzles; just the regular brass nozzles I buy direct from E3D.

At the first sign of any extrusion problem, I have learned that the best first step is to replace the nozzle; there's no point in messing about with cleaning, cold-pulls etc, just swap it out.

I buy 10 at a time to keep the postage costs low and probably replace them about every 8 weeks on average.

I still have the hardened nozzle for abrasive filaments and a couple of plated copper as spares, but the regular brass one is cheap enough to be considered (by me) as a consumable.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Filament should be unloaded to the cooling tubes after a print, but you will see from one of yesterday's posts that the final unload G-code is not quite correct in Slic3r.

ah now I understand your previous posts regarding the G-code, I will check it the next time I slice something.

At the first sign of any extrusion problem, I have learned that the best first step is to replace the nozzle; there's no point in messing about with cleaning, cold-pulls etc, just swap it out.

This changes my perspective on things. I never thought of the noozle as being a replacement part that needs to be swapped regularely, I rather thought that once it's set it should run for months if not years. I hope the steel version will be more durable but yes, from now on I'll focus quicker on the noozle if/when the blockages begin again.

Many thanks Peter, I learned alot from your posts during the past few days 😉

Re: Blockage troubleshooting.

Generally the nozzle wears on the inside and this is prevented by the steel/ruby versions.

However there is still a 0.4mm diameter hole which can become partially blocked by burned filament, dust, PTFE swarf, Festo clamps etc. Ruby or steel nozzle will not prevent this and cleaning will not always work.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

I couldn't even print the temp tower. Just to be sure I tried with T1 as well. Then I tried slow extruding manually from the front panel (i.e. no retracts) - after about 20cm it blocks up. If all this boils down to a nozzle that was broken from the start, I'm going to scream. All I did with it was printing the gears in single color & 4color. Granted that's a lot of retracts, but come on guys?

Re: Blockage troubleshooting.

I couldn't even print the temp tower. Just to be sure I tried with T1 as well. Then I tried slow extruding manually from the front panel (i.e. no retracts) - after about 20cm it blocks up. If all this boils down to a nozzle that was broken from the start, I'm going to scream. All I did with it was printing the gears in single color & 4color. Granted that's a lot of retracts, but come on guys?

It is quite possible that you can't print well with some filaments at 175 degrees, but you should measure to the point where you still get good extrusion; starting from 215 degrees, there is a reduction of 2 degrees per millimetre, so you can work out the ideal temperature for each filament/extruder.

So if the best extrusion is at 5mm, the best temp is 205 degrees.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Filament should be unloaded to the cooling tubes after a print, but you will see from one of yesterday's posts that the final unload G-code is not quite correct in Slic3r.

sorry I am a bit lost here, can you post which code I should add to the G-code to have it unload to the cooling tubes? Because tataa, just got another blockage due to not unloading quickly enough after printing the Calibration Square 🙁

Re: Blockage troubleshooting.

Rafal

Please post your end G-Code here and I will tell you what to change.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Hi Peter,

So if the best extrusion is at 5mm, the best temp is 205 degrees.

I wish I had gotten this far...

After cleaning the nozzle (again) I got very nice extrusion straight from 215 to 190, then blockage. This is spot on the recommended temp range for Ingeo. I'll do one last try at 195 degrees, then replace the nozzle if that also fails.

Edit: I forgot to mention, hotend temp is spot on as well (measured with calibrated PT100 held into the hole where the thermistor sticks). The radiator fins of the heatbreak are slightly warm, about 8 degrees above ambient.

Re: Blockage troubleshooting.

Please post your end G-Code here and I will tell you what to change.

I hope that's the part you mean, generated with Slic3er MMU edition:

G1 X101.439 Y169.414 E0.00703

G1 F2400

G1 X101.031 Y169.343 E0.00750

G1 E-2.40000 F3000.00000

G1 F5760;_WIPE

G1 X101.439 Y169.414 E-0.20479

G1 E-1.39521 F3000.00000

G1 Z28.450 F7200.000

M107

; Filament-specific end gcode

;END gcode for filament

; Filament-specific end gcode

;END gcode for filament

; Filament-specific end gcode

;END gcode for filament

; Filament-specific end gcode

;END gcode for filament

M107 ; fan off

M104 S0 ; turn off temperature

M140 S0 ; turn off heatbed

G28 X0 ; home X axis

M84 ; disable motors

Re: Blockage troubleshooting.

Rafal

Your ending G-code has the unload missing:

; Filament-specific end gcode

;END gcode for filament

; Filament-specific end gcode

;END gcode for filament

; Filament-specific end gcode

;END gcode for filament

; Filament-specific end gcode

;END gcode for filament

M107 ; fan off

M104 S0 ; turn off temperature

M140 S0 ; turn off heatbed

G28 X0 ; home X axis

M84 ; disable motors

This does indicate that you may be using an incorrect profile and the problem is that I don't use Slic3r, so this is a bit of guesswork...

Can you please post a screenshot of the printer end G-Code settings?

TIA

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

Hi Peter,

So if the best extrusion is at 5mm, the best temp is 205 degrees.

I wish I had gotten this far...

After cleaning the nozzle (again) I got very nice extrusion straight from 215 to 190, then blockage. This is spot on the recommended temp range for Ingeo. I'll do one last try at 195 degrees, then replace the nozzle if that also fails.

Edit: I forgot to mention, hotend temp is spot on as well (measured with calibrated PT100 held into the hole where the thermistor sticks). The radiator fins of the heatbreak are slightly warm, about 8 degrees above ambient.

Nils

I think I would be tempted to turn Linear Advance on, with a K value of about 275, print at 205 degrees (first layer 215) and with retraction at 2mm (50mm/s) to see if you still get stringing.

Remember that LA will be turned on until you set K=0 or power cycle the printer.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Blockage troubleshooting.

This does indicate that you may be using an incorrect profile and the problem is that I don't use Slic3r, so this is a bit of guesswork...

Can you please post a screenshot of the printer end G-Code settings?

I am using the original Prusa MMU setting and haven't changed anything in the GCode section nor anywhere else in the printer settings. Here's the screenshot:

Very strange, I thought this profile should be dialed in perfectly for the MMU, so I need to add some code?

Thanks again, your help is very much appreciated 😉

raphael

Re: Blockage troubleshooting.

This does indicate that you may be using an incorrect profile and the problem is that I don't use Slic3r, so this is a bit of guesswork...

Can you please post a screenshot of the printer end G-Code settings?

I am using the original Prusa MMU setting and haven't changed anything in the GCode section nor anywhere else in the printer settings. Here's the screenshot:

slicer.PNG

Very strange, I thought this profile should be dialed in perfectly for the MMU, so I need to add some code?

Thanks again, your help is very much appreciated 😉

raphael