What causes this?

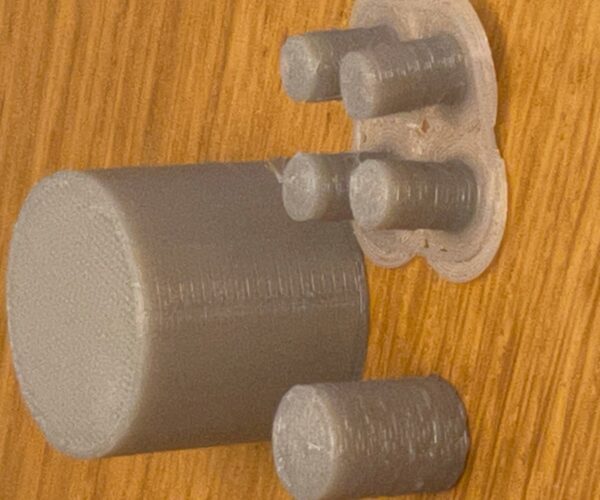

For some reason I cannot print cylinders with smooth sides when printing with PETG. I'm using an i3 and no matter what settings I chose, 0.3mm draft right through to ultra detail I get the same results. This only happens when I do a vertical print, if I lay the cylinder down I don't get the same problems. Rectangular surfaces are not a problem and this has only just started to happen in the last couple of months.

RE: What causes this?

Sae your project as .3MF file, zip it and post the zip file here. That way we can look at your settings together with the part.

Cheerio,

RE: What causes this?

It slices OK but 100% fill does accentuate even minor extrusion variations. Also it's a very small part, a size which I would normally group with others to allow time for it to cool between layers.

Have you been printing these one at a time?

Cheerio,

RE: What causes this?

Thanks for the feedback.

It makes no difference if I select 100% or 10% fill but this only happens on cylinder shapes, as you can see from my photo above a similar size rectangular part prints fine and both are printed as single parts.

It doesn’t seem to make sense to me!

RE: What causes this?

Tried different size cylinders, all with the same print settings, 25mm diameter no problem, 10mm diameter poor, 4 x 6mm diameter poor

RE: What causes this?

It'll be a couple of days before I can test-print some PETG. I generally avoid small parts in PET (except for some spring components) but I do recall single objects as tricky and generally group them into a dozen or so if possible.

Cheerio,

RE: What causes this?

I begin to suspect your belt tension.

The belt tension figure in the LCD menu is a measure of the resistance felt by the stepper when moving the axis. On a correctly set up machine this does equate, roughly, to belt tension.

But other things can affect mechanical resistance.

First, with the power off, move the axis by hand; is is smooth? Does the resistance stay the same over the whole range?

Clean and lubricate the smooth rods, check they are not damaged/scratched. Check the idler pulley is not clogged, out of line, or damaged (loosen the belt and try turning it with your fingertip, is it smooth?)

With the belt loose try turning the stepper motor by hand; is is smooth?

Retighten the belt until it just begins to make a low musical note when plucked...

If the printer works, make your next print this:

https://www.prusaprinters.org/prints/46639-tension-meter-for-the-gt2-belts-of-i3-mk3s-or-prus

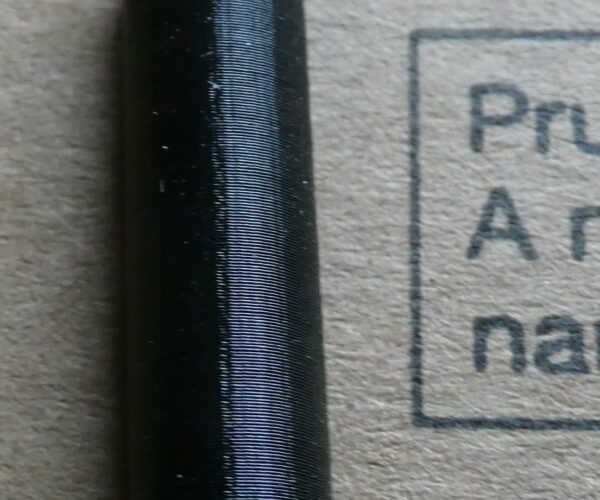

It MUST be printed in Prusament PETG or the spring resilience will be wrong.

Cheerio,

RE: What causes this?

@rong

I would also guess the belt tension. It's best to check the X and Y axles. The tensionmeter is a helpful tool and allows a more precise adjustment than via the LCD menu.

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: What causes this?

Well I checked the belt tension both X and Y axis and both are in the MIN range on the gauge but I can't tighten the X axis any more. I've also changed the print nozzle as the old one had printed 1600m of filament (48 days print time). Results are just the same, this time with a 0.6mm nozzle. I really am stuck with this and it is so annoying, but thanks for your help guys.

RE: What causes this?

As I've run out of fine adjustments for the X axis belt I'm going to re-do the main adjustment on the back of the print head.