Suddenly horrible printing

My school purchased an i3 mk2 (fully assembled) earlier this year. We are new to 3d printing but we are eager to learn. I have printed several of the items which were included with the printer, such as the batarangs (very popular with our students), and several dragons. I have printed some useful things, too, such as a 3.5" hard drive enclosure for a computer. I decided to do something more useful, and started making new door name plates for each teacher's room. It is simply a base of one color with room number and last name of a second color. We used TinkerCAD and the color switcher on-line service at PRUSA.

We made some of the first items with PLA and then switched to ABS for the name plates -- at first, with no success due to lack of adhesion. So we got some Wolfbite and that really worked well. We made several grade levels' worth of plates, with differing base colors. We made maybe 30 or so with great success. For instance:

The name plates are basic white letters on a black base, but as you can see they are just fine. But when I tried to print the last two such plates (or signs), I got this instead:

The plastic was removed from the printer for this picture, and the image shows the results of several such attempts. At first the plates curled up so badly that we stopped the print and tried again. We removed the application of Wolfbite, re-applied it, and tried again, and again, and as you can see the results were worse and worse each time, becoming so loose that the strands never even placed properly.

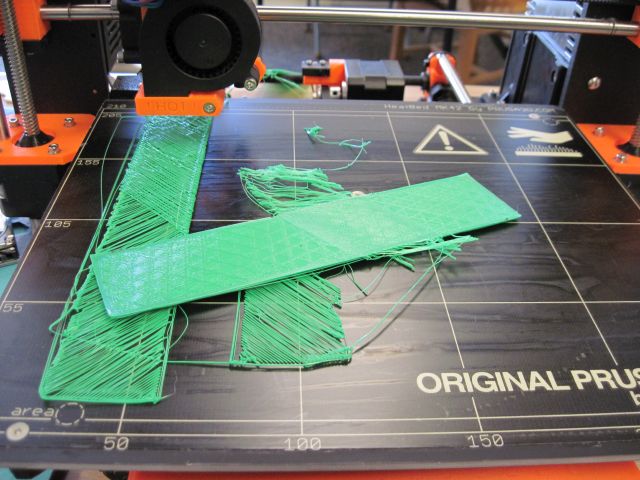

So we considered perhaps the black just wasn't working well, despite the good runs we'd had previously (see first image), and put some green ABS filament back on -- a color we'd used to make an earlier batch quite successfully. Here is the result of that effort:

Next, we cleaned the bed quite thoroughly and tried a run using PLA filament. That worked better, although the edges curled somewhat. But it was usable. Sadly, it was a different green color compared to the ABS green, but it was mostly a test anyway.

So this morning I again tried an ABS print of the last black-base name plate, with a carefully cleaned bed. No Wolfbite this time, because the Wolfbite seemed to have lost its ability to adhere. Of course, we used Wolfbite on all the successful runs. If we can get this figured out, we'll continue to use it because it worked very well at first. I have tried to attach an image both inline and as an attachment, but this forum application might only accept three images. It looks much like the above bad prints, but of course only a single plate.

Since the printer has been working well for several weeks using the same location and filaments, we are at a loss to decide what to do. If you make a reply, please assume we know nothing about settings and physical adjustments, as we did not get the printer as a kit but rather fully assembled. And if you suggest changes to extrusion layers or something, please tell us how because otherwise, we won't be able to implement the suggestions. Remember, we are new to this.

Any help will be greatly appreciated, and thanks in advance.

Donald B. Stinnett

Bradie M. Shrum Elementary School

Best regards,

Donald B. Stinnett

Re: Suddenly horrible printing

Sounds like clogging in the extruder. I would first try raising the temp to maybe 250-260 degrees and manually push through a length of filament. If that doesn't work try a cold pull (if you don't know what I'm talking about feel free to ask back).

This can happen when prints are hard-aborted and soft filament gets stuck in the heatbreak, or when swapping from high-temp to low-temp filament, or when there are gaps somewhere in the extrusion path, or when the nozzle reached end-of-life. To name only a few reasons.

It's a very common and recurring issue in FDM printing, sooner or later you'll get the hang of it.

Re: Suddenly horrible printing

We discovered the gear (?) which pulls the filament had gotten clogged with "stuck" filament, which occurred when the filament would not advance and so the gear-like teeth of the unit filled with scraped-off filament and thereafter was not pulling the filament very well -- that is, the gear kept turning even though the filament was not advancing, so it gouged an indentation in the filament. We cleaned that as well as we could -- not easy, because it takes a fine tool -- and then cleaned the bed, applied Wolfbite, and tried printing the batarang (ABS) since that is quick and an error would appear soon. It appeared to be working nicely except that it just does not adhere to the bed, despite the Wolfbite. It kept curling up at the edges more and more until the whole thing came loose, and that was it. We had to stop the print. So adhesion is a real problem.

Also, the extruder "leaks" some filament whenever we change it. Once we have said "Yes" that the filament is clear, it no longer advances via the gear, but some plastic still drops out in a thin strand. We'll remove that, but a tiny bit will still come out. This happens two or three times. If we don't notice it, it usually curls up onto the extruder and we think that may have contributed to the original condition of bad printing.

Does any of this make sense? Again, any help will be greatly appreciated.

Best regards,

Donald B. Stinnett

Re: Suddenly horrible printing

Its essential to make sure your live-z is adjusted properly. See this thread: https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/life-adjust-z-my-way-t2981.html (read at least the first several pages if you haven't already).

What are you using to clean the bed? It looks kind of streaky in the photo with the green filament.

Clean the bed between prints with isopropyl alcohol (90% - or as high a percentage as you can get).

An occasional through cleaning with acetone will improve adhesion. Don't use fingernail polish remover as some of it contains oils - you can get pure acetone at a hardware store.

You can also rejuvenate your pei sheet by scrubbing lightly with the rough side of a kitchen sponge (or scotch-brite pad). Some users say fine steel wool works for this also.

I haven't printed with ABS but it seems common to use an enclosure for this - low temperatures or drafts can cause problems with warping.

-Kevin

Re: Suddenly horrible printing

A little drooping of filament during heatup or idling is perfectly normal. The printer will drop it when printing the purge line. Frankly, I've given up on ABS without enclosures. There are some ABS mixes that print fine (e.g. Formfutura TitanX works quite well for me), but you never really know what you get. For many purposes PETG-based filament does the job and prints way easier and afaik don't produce toxic fumes.

Now personally I have never had success getting ABS to stick using spray. I don't know what Wolfbite is, I use normal hairspray or 3DLac (which I'm sure is also just hairspray only more expensive). Assuming it is similar, it works really well for flexibles and PLA but is not really needed unless the part footprint is small. PET-based filaments need no adhesive on PEI, you actually will have problems getting them off. ABS works best with ABS slurry (which is a terrible mess and acetone leaves stains on almost everything), second best with a very clean degreased (IPA rubdown) plate.

But you need to get the Z-offset exactly right for your filament type on the MK2s. Supposedly this works better with PINDA2 on MK2.5 and up (true, anyone?). Some filaments need to be laid down, others need to be squashed.

Re: Suddenly horrible printing

Kevin and nils.t,

Thank you so much for your comments. We are learning as we go. We have been afraid to do ANY adjustments to the printing mechanism because we fear ruining everything. Since we got the printer assembled, not as a kit, we assumed all testing and corrections had been made. We were afraid to mess things up. Since this is for an elementary school (grades 4 and 5 to use the printer, mostly) we had hoped it would "just work."

ABS ... yes, quite a problem. When we got the printer we knew nothing about filament types. We got about 60 rolls of filament, about half ABS and half PLA. We wanted the supply to last an entire school year. Because we didn't know the problems with ABS, we did not know to get an enclosure. Since we've had these problems, I have read more on it and an enclosure would certainly help, I am convinced. I'll be looking into that. I don't like the idea of just throwing away all those rolls of ABS filament.

I will definitely try that calibration sequence you recommended, Kevin, to see if we can improve the layering. Having said that, I have to add that we really haven't had issues with the surface until just the past few days. When we first got the printer, with excitement we loaded PLA and printed several of the sample files included with the PRUSA SD card. We were amazed. "This is going to be great," we thought. When we tried the ABS filament and had the result wander all over the bed, we went back to research mode and learned ABS does not adhere well because it cools at the edges and curls off the bed. Eventually is takes the entire product with it and of course that's a disaster. The PRUSA video tutorial mentions "ABS juice" and I looked that up.

So, we decided on the Wolfbite "glue." nils.t, that's just a brand of liquid (ABS juice) which enhances the adhesion of the extruded plastic on the heatbed. I wouldn't really call it a "glue," it just makes the bed stickier. This is what it looks like:

When we applied that stuff, it really made a difference. Kevin, that is the "streaking" you see in the picture of the green filament. You're seeing the Wolfbite coating. It goes on the bed when cold, and is left to dry. It applies in a very thin layer, very water-like in consistency. But boy did it work. Although there was some little bit of curling at the edges of things, it made a remarkable difference.

That's when we got to work making the door signs for the rooms. We wanted to use the ABS filament and then use only PLA once we ran out of ABS, so we were thinking of anything at all to make in ABS to use it up. The Wolfbite made it easy. Even better, you don't have to re-apply for each item. It lasted for at least 25 signs. Then we started getting the "wander all over the bed" problem again -- but this was expected. We knew the single Wolfbite application would not last forever.

So we cleaned the remaining Wolfbite off (it comes off with simple water) and cleaned the bed as thoroughly was we knew how, waited a bit, and applied a new layer of Wolfbite. We expected to continue making the signs with the same good results as before. We were wrong! The new Wolfbite did not help at all. We tried printing the same things as we'd printed before, swapped filament, even cleaned and reapplied the Wolfbite (three times). That's when I made the original post to this forum.

So I will try the calibration code suggested by Kevin, and see if that helps. I certainly hope so! Thanks so very much to both Kevin and nils.t for your comments. Once we get through this supply of ABS, of which we have plenty, it'll never be seen around here again, I can promise you that. The PLA seems to work better but we have so much ABS ... !

Best regards,

Donald B. Stinnett

Re: Suddenly horrible printing

FYI: printing with ABS will degrade the PEI sheet on the bed at an accelerated rate. PEI becomes brittle with exposure to Acetone.

when printing with ABS usually you need Juice which contains acetone. when cleaning up the PEI after abs print to get the juice off you need to use Acetone. So it goes hand in hand at some point when removing a part from the PEI sheet a chunk will snap off requiring replacement of the sheet.

you can use Tapes instead of the juice but the tape tends to pull off. that was part of the change to the newer printer mk3 with replaceable bed sheet where there is a very rough PEI sheet that ABS sticks better to without ABS juice.

that said: ABS requires higher temperature so i would re-calibrate the PINDA at a higher temperature then usually you need to bump live z down some more.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Suddenly horrible printing

OK, thanks for explaining your motivation. I feel with you, it just sucks to have filament around you'd rather not use. It seems like you have an ABS-rich filament, there are now a lot of "easy ABS" mixes around that print much easier. It might have some advantages if you have a school lab to mess around in, since ABS can easily be vapour smoothed to shininess. Also you can bond ABS parts with acetone. In principle this is possible with other filament types but then you need more "interesting" solvents and there would be safety aspects to consider.

Anyway, 30 spools will go fast in a school so I wouldn't bother with an enclosure and just use a cardboard box big enough to accomodate the printer. Cut a little access flap so you can use the rotary. It doesn't look very professional but will definitely improve things a lot.

Apart from live Z offset (which is not maintainance but standard operating procedure, so you'll need to get used to it), you can use rafts, brims or bunny ears. All of those need to be removed in postprocessing and could leave marks. Bunny ears are just spherical, 1-2 layer high additions placed strategically at corners in the model to pull them down (I design my own stuff but iirc you can do it in Meshmixer and there's a forum post how to do it in Slic3r here: https://shop.prusa3d.com/forum/print-tips-archive--f86/adding-helper-discs-t5315.html ). Brims and rafts can be added in the slicer. Rafts can add significantly to the print time and will make the bottom sides of your prints quite ugly.

There's a pretty good starter guide on ABS printing, just ignore the bit about Kapton on glass (for our purpose PEI = Kapton):

https://www.matterhackers.com/articles/how-to-succeed-when-printing-with-abs

Final advice: Always, really always stick around for the first layer. Check from a flat angle if the filament is properly laid down (what is "proper" depends on the type). Don't be shy to use live Z adjust, it's one of the best features of this printer (the problem probably exists for all printers and getting the offset right can be a real pain with a lot of common designs). Everytime you do a cold pull, nozzle clean or other maintenance of the hotend, the offset can change but the relative difference between filament types will remain the same. If you write it down you'll soon have good consistent values relative to PLA for all your filament types. In my experience PLA is quite forgiving in terms of offset (except prints falling off when too far and uneven extrusion or nozzle blockage when way too close), but all other filaments are not. Gettings this right is really the most important bit.

Re: Suddenly horrible printing

We continue to struggle with this problem. We keep having issues with adhesion, even though we have abandoned our ABS spools and now we will use PLA only. Yesterday I went through the calibration steps and everything seemed to be properly aligned. One thing I sure could use advice on is that aspect of the calibration when you print the zig-zag pattern (I believe this is the "Z" calibration) and the manual says to watch the filament and adjust Z until the extrusion is being squished just a little. How is it possible to tell that while it's happening? I'd need a microscope to tell the difference.

Does anyone know why this would have begun so suddenly (the terrible print results)? It was literally from one door sign to the next. I could tell the previous one or two signs started to come loose at the corners just a bit, but I concluded the Wolfbite had come to the end of it useful life on that application and the only thing we did between signs was to clean the old Wolfbite off and apply a fresh layer -- the previous application had lasted for about 25 items so I thought that was a decent number.

This morning I inserted a new filament and tried to print something simple: the batarang included on the SD card which came with the printer. We've printed a dozen or more of these for students without flaw. This is a relatively quick print, so I used it to test. I cleaned the bed properly and made sure the filament was flowing nicely before saying it was "clear." Here is the result of my first effort:

As you can see, rather awful. This is just the first layer! I immediately stopped the print. Our earlier prints had never had this stringy appearance with the gaps between extrusion lines, but it is typical of what I'm getting now on everything.

More cleaning, and another trial, this time lowering the Z to -0.700 and slowing it down to 88% speed. The result was much better, and I thought maybe we were back in production since the print was almost complete -- but then the left edge came up. Seconds after taking this picture (the printer was in-motion when I took this), the entire thing came loose and started wandering over the bed as the printhead moved. Of course I stopped it at once.

Well, fine, let's try yet again. This time I allowed the speed to return to 100% (the same as we'd printed everything before). See how it turned out:

We have spent the past two, maybe three, weeks trying to work this out. Does anyone know if these printers can be serviced, and an experienced technician fix this?

Best regards,

Donald B. Stinnett

Best regards,

Donald B. Stinnett

Re: Suddenly horrible printing

Hello Donald,

Looks to me like a z-adjust problem. (At least, it is possible for me to get things looking/acting like that when my z is too high.) Did you use the script given in the link by Kevin and adjust z to get a uniform sheet of ~0.2 mm thickness. If not, I'd suggest you try to do so. (The end of the z adjust script in the latest firmware generates a test flat after the serpentine pattern as well.)

Now, if it that is the problem, why suddenly now? Possible issue with the pinda probe: When you try to do the above, raise the z axis up a few inches before you start each print so that the probe is seeing the same temperature profile each time.

Best Regards.

Re: Suddenly horrible printing

It is is nozzle related. The simpliest solution is to change the nozzle. When it comes to Z height keep in mind that PINDA probe is sensible to temperature, so i.e that depending on the bed temperature you will need to adjust the Z height.

Re: Suddenly horrible printing

john.d36 and nenad.b,

I was able to get an acceptable print of a nameplate after lowering the Z to -850! I think that is an unusually large value and I worry about a "head crash" onto the heatbed, but that's what it took to get something presentable. I will try other prints soon and see if I continue to get acceptable results at that adjustment. And I did try the test patterns suggested by kevin.r5 but they all turned out stringy. Not one of them resulted in a coherent square of plastic. I didn't go lower than -650 in those tests, though, because the author said it would risk damaging the headbed, which I certainly wanted to avoid. However, I got desperate and so kept lowering it down to the -850 point, which is where I am "stationed" now.

nenad.b -- You mentioned replacing the nozzle; this printer has barely created three dozen items. If it wears out the printhead that swiftly, then 3D printing is not at all what we thought it would be. My school wants me to print quite a few door plates for fire code use (about 200) and if I have to replace the nozzle every 30 prints, we'll be keeping the nozzle manufacturer in business for sure.

Thanks guys for the advice and tips.

Donald B. Stinnett

Bradie M. Shrum Elementary

Best regards,

Donald B. Stinnett

Re: Suddenly horrible printing

Hi Donald,

My last post was quite short. Let me give the long version. I ran exactly in the same problem like when printing ABS. I contacted support and they suggested that I remove the nozzle and put in acetone bath over night. I resolved the issue by myself by first using the "cleaning" filament which I loaded/unload for dozen of times. When printing same roll of ABS I had to use flow factor of 1.20 and everything was in order again. It is not perfect but it works.

Now, about lowering your nozzle, it is way around but it not such idea. Let's analyse the problem. Somehow when printing plastic material got deposed in intérieur of your nozzle what caused the under extrusion. When your lower the nozzle, you create additional pressure and putting your printer on the strain.

My bottom line here is that what you need to print PLA would be perfect. Forget ABS

Re: Suddenly horrible printing

Hello Donald,

As long as your pinda probe is physically in the correct location, don't worry about what the z value actually is too much. If you were not impacting the build plate enough that you were just getting stringing, it probably needed to be lower as you found out. So, if it's working, then great. As stated though, make sure you start with the print head raised up a few inches each time because the probe is affected by temperature.

Why did it change? The temperature effect and the adhesion difficulties of ABS explain why some people need to have a higher |z| value when going from PLA to ABS, but you have been using ABS successfully. Perhaps the pinda probe moved down slightly and you need to check to see that it's tight? Perhaps you changed to a new spool of ABS and the diameter is significantly different? Perhaps, as nenad suggests, you have a blockage in your nozzle that needs to be cleaned? Perhaps it's something else? If it's working for you now and you don't care, don't worry about it and wait to see if some other problem is generated. Otherwise, I suggest to get some calipers and check first layer thickness, extrusion diameter, etc. If nothing else, it can give peace of mind that things are functioning properly.

Re: Suddenly horrible printing

Hi Donald,

My initial liveZ was around -1.300 mm

it worked fine, but I was uncomfortable with that value, so I moved the Pinda up about one turn (loosened the clamp bolt, pried the plastic a little with the flat screw driver and slid the pinda, rather than turning it... liveZ is now -.442

your pinda could go up say half a turn, but be careful as the cable has to absorb that half turn... which is why there should be a loop of cable above the Pinda.

on non abrasive filament a brass nozzle should last many rolls of PLA. providing you are not in a very dusty environment and you don't bake the filament in the extruder...

sometimes you get a blockage which can take a while to clear and it would be beneficial to have a spare nozzle so that you can change, and clear the other at your leisure.

you will eventually need a new nozzle, and they are inexpensive, why not get one in stock, so that you are ready...

I initially got a mk1 with a V6lite extruder, I did change the nozzle periodically, for different sizes, but never wore one out,

at least I never noticed it wear out...

I upgraded to mk2 with full V6 extruder, this brought a new nozzle which I again changed periodically for different sizes, don't recall that one wearing out either,

upgraded to multi media, that brought a v6.1 extruder with a new nozzle, and I have never changed that one... not even for a different size.

my mk3 has been working since the beginning of the year, and that's never had a nozzel change either

in my experience most blockages are self inflicted and normally easy to correct... YMMV

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Suddenly horrible printing

Hello again everyone,

To bring everyone up to date ... with the extruder down to the -0.850 level, I got a decent batarang (those are a good test because quick to print, and flat). Then I tried a door sign, which I'd been using this printer for all along. It also came out fine. Well, maybe -0.850 was it. It bothered me that it was so low, so I ran the "PRUSA" test logo included on the SD card. It ran perfectly, and I even raised the nozzle to -0.800 and it was still pretty nice, so I thought, great, that's the new normal and that's what we'll use.

So I tried to print the gears-spinner thing, which takes 5 hours, and is also included with the SD card. It actually seemed to be going well, and I had to leave the room after about 45 minutes of printing; when I came back maybe 30 minutes later, the circle which had already built up was displaced and there was a significant accumulation of filament all over and around the print head, but none on the newly-cleared heatbed. Immediate cancel-print time. That gobbed-up bundle of plastic proved difficult to remove once it cooled; I heated the nozzle to 220 or so, in order that it get enough heat to be largely liquid. I cleaned that area as best I could; all the plastic came off, but it still looks rather "burned" -- maybe that's normal as an extruder gets used.

So now what to do? I am not going to move the PINDA probe up just yet, but only because I'm afraid I'll break it. Maybe I'll have to do that, but not now, not with such a new printer. So I'd like to try cleaning the nozzle, as suggested by john.d36 and nenad.b; so what is that process, guys? What is a "cleaning filament" nenad.b? And someone also mentioned a "cold pull" earlier -- how to do that?

If I have to remove the extruder-print head, is that easy to do and will it mess up the calibration? I am willing to take it apart if I must, but it's so new, I am amazed that this might be necessary already. I'm the school's computer tech guy so I am perfectly at ease taking things apart to fix them, but I want to be sure of what I'm doing before I ruin a new 3D printer ...

Thanks again.

Best regards,

Donald B. Stinnett

Re: Suddenly horrible printing

Oh, and by the way, we'll no longer be using ABS. From here on in, it's PLA all the way. I made the batarang, door sign, and attempted gear-spinner all in PLA.

Best regards,

Donald B. Stinnett

Re: Suddenly horrible printing

Hello Donald,

I don't think you need to move the pinda at this point unless you have the problem of it colliding with your build while moving around. As far as your problems, I'll stay with it being a live Z adjustment/bed adhesion issue until there is more data. I don't see how an extruder blockage causes your problem unless complete because the volumetric amount of filament is set by the extruder gear and not the nozzle. (If you measured the filaments' diameters, there would be no need to guess.) If nenad has had this experience though, I'll posit that it could affect it through some other path.

For cleaning things/unclogging, I'll have to point you to a search. There's a lot already posted as well as an article on the knowledge base maintenance page, and I have not had the need to do much of that. I know Joan recently posted some of the things she does for maintenance, and I believe she "scrubs" the outside of the nozzle using a wire brush-- Joan is very unassuming but it is obvious after reading some of her posts that she has FAR more experience/knowledge than me and most everyone as you might guess by her post count and Moderator status. The only thing I would add is that if you actually want to find exactly how to do the cold pull, it helps to know that it is also called the Ultimaker Atomic Method and is described on the Ultimaker web site.

Re: Suddenly horrible printing

john.d36,

I don't think I want to do anything on this printer which has the word "atomic" associated with it. That sounds like a last-resort approach, plus, I don't want to go home and glow in the dark.

I just finished printing a good version of the spinner-gear thing included on the SD card which came with the printer. Leaving the 'z' factor low (high negative value, -0.800 or -0.850, forget which at the moment), it printed (6 hours 24 minutes) and I can't distinguish it from the first one we did when the printer was fresh. I had cleaned the bed of any extra adhesive -- Wolfbite, gluestick -- and it adhered just fine, no wandering over the heatbed. I actually tried to print it two-color using the gcode change generator on the PRUSA website but I must have missed something; it never asked for a filament change. One of my students did accomplish this (witness the name plates we've been printing all along, which are two-color). I'll have to ask him!

However, for now, using PLA, we've gotten a couple of proper prints, albeit with the extruder head at a seemingly-low value. At this point, if I can get the fire code signs made for the custodial personnel, I'll be content. ABS is hereby banished from the kingdom, however.

I will update this thread in a few days to let everyone know how things are going. I greatly appreciate everyone's help and comments.

Best regards,

Donald B. Stinnett

Re: Suddenly horrible printing

Hi Donald,

the most likely error is to use

m600

instead of

M600

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK