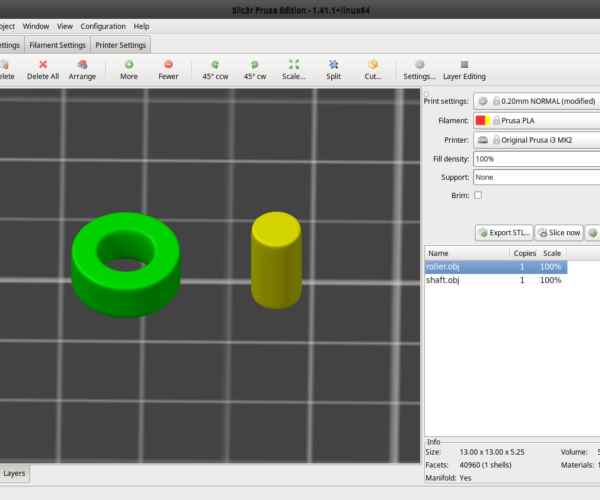

Trouble printing concentric infill patterns (slicer bug?)

Hi all,

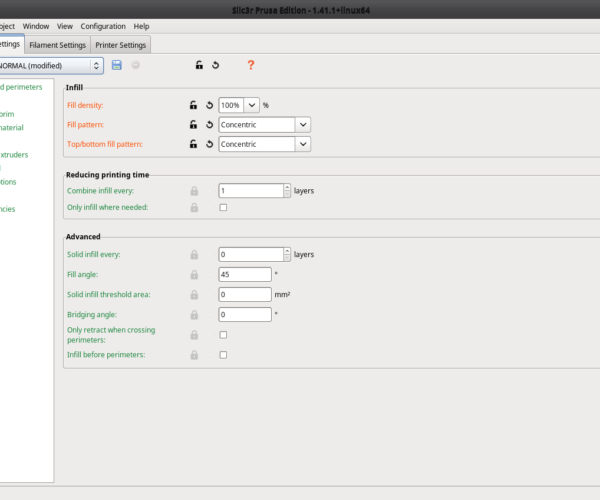

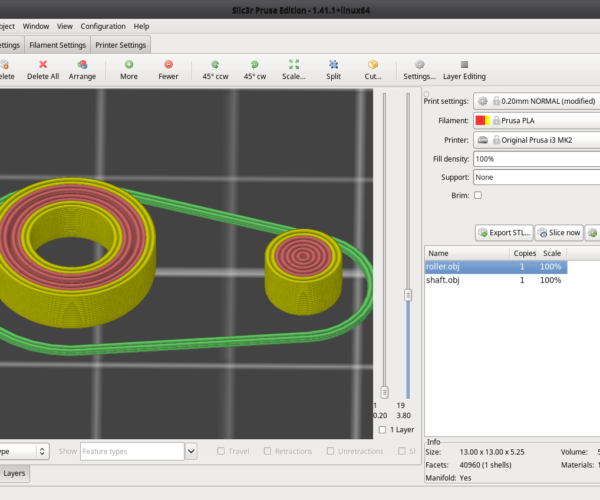

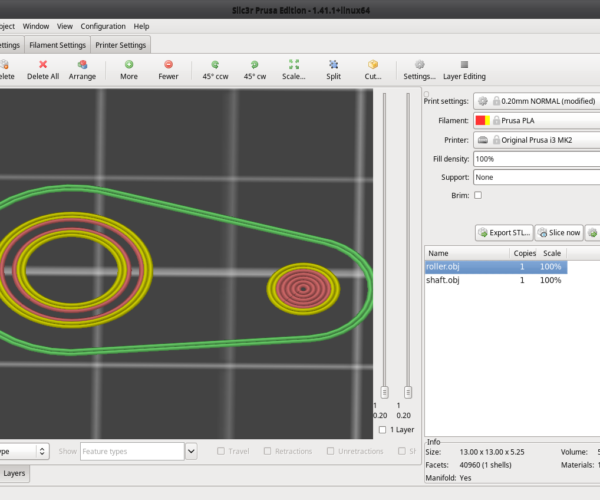

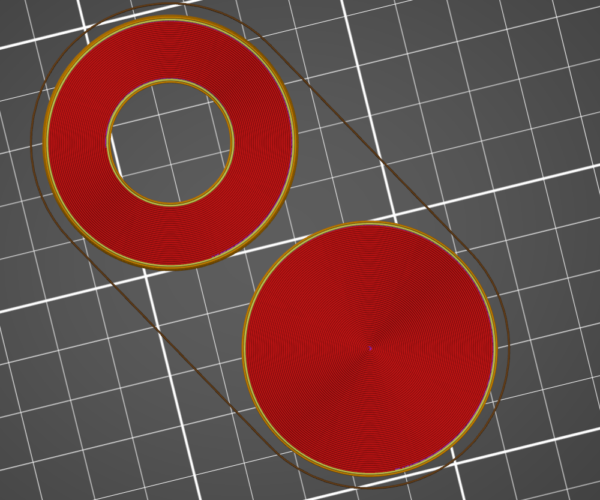

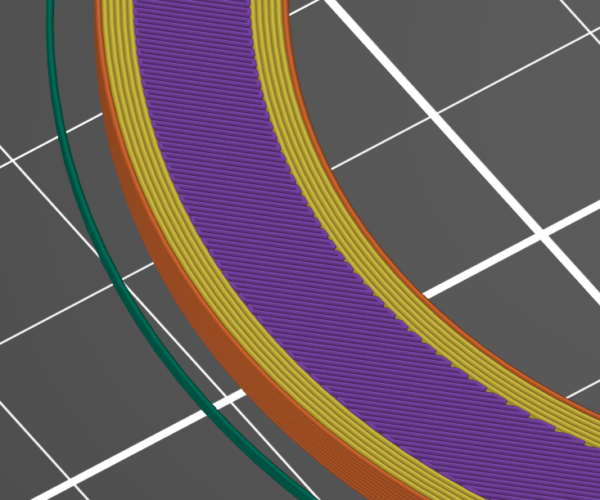

I encountered a problem when slicing circular objects, and use a circular infill pattern: the infill is incomplete, it leaves gaps between circles. Please see the attached images to understand what I am referring to. The biggest problem is on the first layer - it's printed as if there are two separate objects, leaving a large gap between infill circles.

Is this a bug in the slicer, or is there something I do wrong? Any advice is greatly appreciated.

RE: Trouble printing concentric infill patterns (slicer bug?)

This is a known issue with concentric infill; it doesn't do well in finer details or objects that can't fit a "perfect" number of extrusion widths.

I do not know for sure but it may have been fixed in SuperMerill's community version, PrusaSlicer++

RE: Trouble printing concentric infill patterns (slicer bug?)

Do you have elephant foot compensation on? I notice if you use a cylinder modifier to make circular perimeter it too treats the modifier as a separate object and shrinks the first layer leaving a gap.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: Trouble printing concentric infill patterns (slicer bug?)

Do you have elephant foot compensation on? I notice if you use a cylinder modifier to make circular perimeter it too treats the modifier as a separate object and shrinks the first layer leaving a gap.

Ah! Yes, john-h68, I do have the elephant foot compensation set around 0.05mm. Thanks for the tip! I'll try without the compensation, see if it works.

@vintagepc: Thanks also for the info. The part, as you can see, is small (13mm, approx. 1/2 inch diameter), and I could solve the problem temporarily by increasing the number of perimeters to 4. However, I was unlucky with larger cylinders - too many perimeters, right?

I'll try the following: a) switching to Prusa Slicer 2.10 (although I definitely don't like the interface!); b) remove the oliphaunt foot compensation, c) test with different extrusion widths to have an integer number of infill circles. Will report back what I've found.

Kind regards,

ferdinand

RE: Trouble printing concentric infill patterns (slicer bug?)

After many tests here's what I observed:

1. With respect to the concentric infill problem, there is no difference in slicing between 1.41.1+ and 2.1.0+ versions. Both versions (head to head) exhibit the same behavior. So, it's not a version issue, but rather a software design issue. (Philosophy, design approach, math? I don't know.)

2. The problem exists with- or without- elephant foot compensation.

3. Although the circular infill has been selected for all options, the slicer still produces linear infill on some layers (!).

4. It is indeed an issue of the concentric infill fitting an integer (or "perfect" number, as @vintagepc said) of extrusion widths: Adjusting the 1st layer extrusion width to nozzle width (0.4mm) makes the gap in the torus disappear, while creating a gap in the cylinder. Making different adjustments, one can see how the gap widths are indeed dependent on the selected extrusion width. The dependence is observed in greater detail at other layers (e.g. layer 12). The gap dependence on the extrusion width is reproducible with a different nozzle (0.25mm) and different layer heights (0.15 and 0.1mm). Only difference was, with a 0.25mm nozzle the 1st layer extrusion width was set a 0.275mm for a gapless infill.

I am attaching the stl file to this message. If someone can successfully slice it without gaps between concentric infill at 90-100%, I would appreciate if that person can provide the settings for the successful slicing. I could learn a thing or two from it.

Kind regards,

ferdinand.

RE: Trouble printing concentric infill patterns (slicer bug?)

Update: since the forum rules don't allow attaching an .stl or .obj file even when zipped, here's the link to the .stl file on the Google drive:

https://drive.google.com/file/d/1wbJvy0iwIznO7rGA1lVOWJsKnz6no21w/view?usp=sharing

Kind regards,

ferdinand

RE: Trouble printing concentric infill patterns (slicer bug?)

I just noticed this problem too. I'm trying to make some decorative knobs for electronics, and somehow the knobs with a D-shape in the middle make for an uneven concentric shape that needs to be fixed at some point. I expected it to do gap filling where needed if it makes gaps, but it doesn't do that, making for really ugly finishes.

Creative Engineer and 3D printing @ AcEcraft.eu

RE: Trouble printing concentric infill patterns (slicer bug?)

Is this a bug in the slicer, or is there something I do wrong?

Yes, there is something you do wrong.

The slicer cannot work miracles. If you do not permit it space to infill, the pattern must either be a multiple of the extrusion width, or it must have a gap.

So: in future either set the thickness according to the extrusion width, or reduce the number of perimeters so the slicer has room to insert padding.

Cheerio,

RE: Trouble printing concentric infill patterns (slicer bug?)

In my case I wanted concentric top/bottom layer and 100% infill. Set the number of perimeters to 100 so it was all perimeters. Functionally the same as concentric infill

RE:

Yes, there is something you do wrong.

The slicer cannot work miracles. If you do not permit it space to infill, the pattern must either be a multiple of the extrusion width, or it must have a gap.

So: in future either set the thickness according to the extrusion width, or reduce the number of perimeters so the slicer has room to insert padding.

Cheerio,

That's the problem, the slicer doesn't seem to create a gap infill at all. Usually you don't need perfect spacing, that's what the gap infill is for. Well at some instance I've noticed gap infill with concentric, but it's erratic. This also doesn't explain why only my bottom and top layer are concentric but all the other layers are rectilinear or something similar.

With "all perimeters" I at least get concentric features in every layer but with concentric infill I only get concentric top and bottom layer.

Examples:

This image shows the 1st layer with everything "concentric infill" and every layer 0,3 mm height. (no gap fill, although there should be)

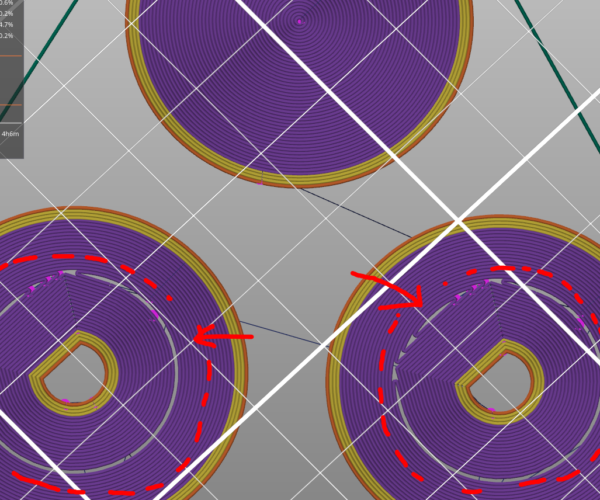

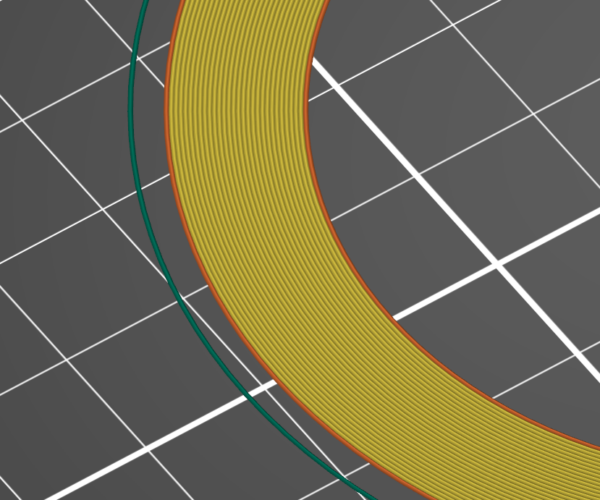

This image shows a random layer (no concentric infill at all but another random layer somwehere in the middle has concentric infill, so there are 3 layer in total with concentric infill: top, bottom, 1 random layer somewere between them, which is weird)

Also: There is only exactly 1 top and bottom layer with concentric infill although the number of top and bottom layers is set 7 and 6 respectively.

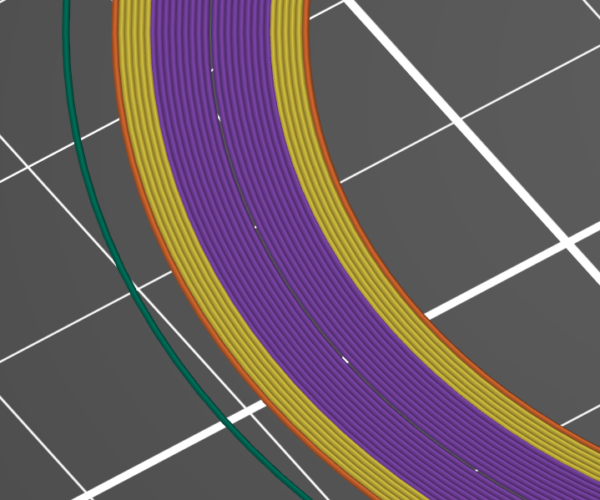

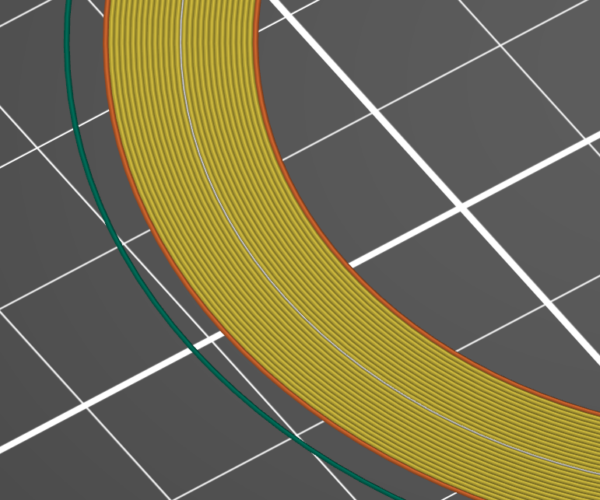

I'm now increasing # of perimeters so that everything is perimeter. All other layers look exactly the same. (now we have concentric features everywhere and that is what I was doing all the years, not using "concentric").

Note: at the very beginning I tuned the extrusion width to the width of the model so without that even in this case there would have been a gap or at least gap fill of a different width than the rest of the extruded perimeters. So this is exactly the same extrusion width and layer heights as image 1 just with "all perimeters" instead of "concentric infill". Suddenly: no gap. (probably because of infill/perimeter overlap I am realising now)

There is another thing: decreasing the first layer height von 0,3 mm to 0,2 mm but leaving the extrusion with the same everywhere, does something to the extrusion width anyways and a gap fill is created. (why? and why do we get gap fill here but not in the above case?)

Note that with "concentric" there is a real gap in the middle, even in the perfect case leaving the extrusion with untouched and every extrusion width being the same. -> because of infill to perimeter overlap

Soo, I noticed while writing that some things are most probably being caused by the infill to perimeter overlap setting.

But that doesn't explain the shrinking extrusion width in the first layer when it changes from 0,3 mm to 0,2 mm and it also doesn't explain why all the inner infill layers are rectiliniear infill plus 1 random concentric infill when using...concentric infill. Oo

RE: Trouble printing concentric infill patterns (slicer bug?)

Interestingly enough "perfect" parameters don't seem to work. My previous "perfect" model had a width of 10,2 mm. With an extrusion width of 0,4 mm we get 25,5 extusions in there. Yet it fits with just a tiny irregularity in the center.

In hopes of getting rid oft that I modified my model to 10 mm width and that should fit 25 extrusions. No elephant foot compensation, no xy-compensation and no infill overlap.

For some reason there are not 25 but 28 extrusions and a gap in the middle.

I tried reducing it by 1 extrusion to make it an even number by making my model 9,6 mm wide but now it's 26 extrusion instead of 24 and a gap in the middle. So it't not about being even numbers.

Then I tried tunig the model to make the infill as seamless as possible, without any discernable irregularity in the middle. And I ended up with 10,18 mm . The fact that the number of extrusions in the slicer doesn't match the calculated number is accompanied by them indeed looking a bit smaller than the perimeter extrusions in the slicer. Although everything is set to 0,4 mm extrusion width. I can't think of any parameter responsible for that.

RE:

In my case I wanted concentric top/bottom layer and 100% infill. Set the number of perimeters to 100 so it was all perimeters. Functionally the same as concentric infill

Usually I do it this exact way.

I my case, though, (the 2 posts) it's not exactly the same, because it creates a seam right in the middle of my seal to be. I think this is interfering with the surface against wich it is supposed to seal (although at this point in praxis testing the whole thing, it might not even be the seal's fault)

The printer would print from the center of the wall to the inner face of the seal and then again from the center to the outer face. I doesn't do the surface which I want to be the seal in one go. (Reversing perimeter print direction might be worth a try, also.)

So I tried concentric infill again. In this case it should print the perimeters, which are far away from the the sealing surface, and then print the inner part of the seal in one go, having no seam in the middle but rather 2 seams at the fringes of the seal, which don't matter.

Just FYI, though. Or anyone's interest. Kinda niche.

RE: Trouble printing concentric infill patterns (slicer bug?)

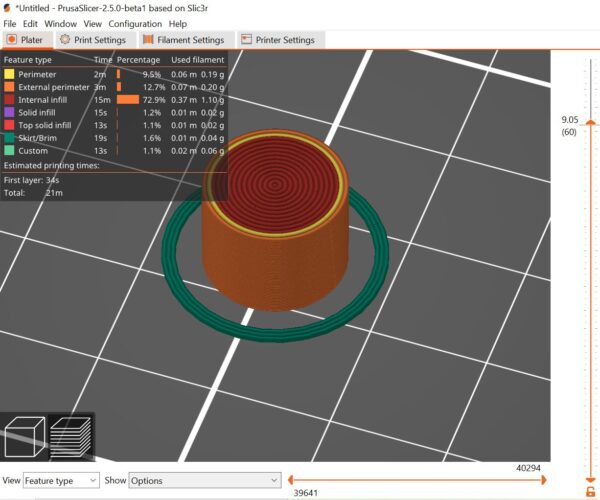

Try Prusa Slicer 2.5.0 beta1, disable elephants foot, select 1 top layer and one bottom later, set minimum top & Bottom thickness to 0.0mm, set infil concentric 100%

and slice with 'Arachne'

should work for you

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Trouble printing concentric infill patterns (slicer bug?)

Look forward to the software update.

and slice with 'Arachne'

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: Trouble printing concentric infill patterns (slicer bug?)

you can download the update today

https://github.com/prusa3d/PrusaSlicer/releases

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Trouble printing concentric infill patterns (slicer bug?)

Mind blown. Thanks a lot 🙂 .

Arachne FTW! (all the other feature are cool, too)

Why does non zero minimum shell thickness lead to a different infill pattern though? Oo

RE: Trouble printing concentric infill patterns (slicer bug?)

To be honest I don't really know why non zero thickness causes different infill...

It seems that you can choose top layer infill, body infill and bottom layer infill, but any supplementary top or bottom layers, seem to default to a different infill...

regards joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Trouble printing concentric infill patterns (slicer bug?)

Only the very top layer (or bottom layer), the visible ones uses the selected fill pattern for that area. Say you have 5 top layers configured, then only the topmost would use concentric, the other 4 would use normal rectilinear. The cross hatch pattern is arguably the simplest/strongest pattern so it uses that and then the pretty outer layer it uses whatever you set.

Can you imagine 5 layers of Hilbert Curve being printed directly over infill ? Without a LOT of infill % it would just sag into the voids. Or even 5 layers of concentric, the layers would stack with the joins to the extrusion next to each other, all on top of each other which would make a weak surface. You would have all the weaknesses of layer adhesion but on a flat which is normally the strongest orientation for 3d prints.

RE: Trouble printing concentric infill patterns (slicer bug?)

Ah, I see now. Only the outer layer of top/bottom shells is the chosen pattern. Everything else of that infill ist 100 % rectiliniear (or something that works with 100 %). And then again the internal infill is what you choose again. In case of the hilbert curve it's the same curve stacked, though, so no sagging. You could do that with the top/bottom shells too but I guess you have 2 choices this way: Printing with top/bottom makes always a closed surface. If you don't want that or use the the internal infill I guess you could just set them to 0.

I guess I lost sight of the fact that top/bottom shells are supposed to be solid.

The 2nd outermost layer might interfere with the outermost layer, though. I'm using the concentric pattern to make the seal actually work. If the rectilinear pattern from below imprints on the outer layer that might be functionally bad or maybe even visible. But then for this very niche application one could probably use modifiers. Or like I do now, just the internal infill.

Thanks for the clarification, I feel much better now that I can see a reason and the connection between top/bottom shells and rectiliniear infill. 🤪