Z seam issues on thin wall prints

Hello everyone,

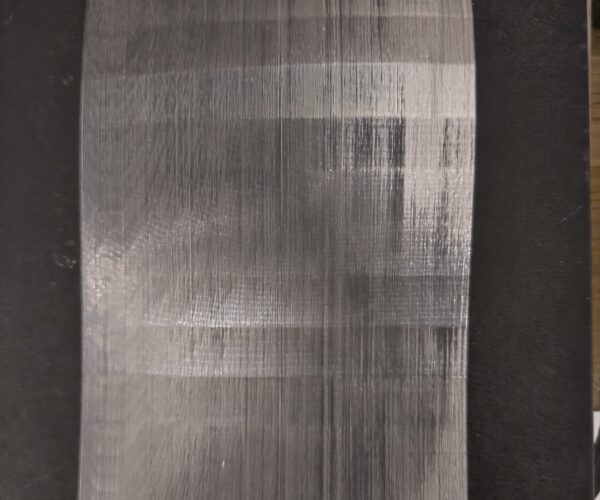

I'm printing these very thin pieces that have a 0.4 wall width with a 0.4 nozzle at 0,15 layer height, and am getting strange gaps at the beginning of the layer, with th Z-seam placed at the extremity of the wall.

The first issue arrived when first printing a big batch of these thin wall pieces, the Z-seam was centered on the piece and showed ots of gaps (1-2mm) between the two strokes of the layer.

I re-sliced with a painted seam on a large batch, placing the Z-seam at the extremity by using the seam painting tool for each piece. I stopped the batch because I was noticing "steps" on the Z seam.

My online research has led me towards thinking that this issue could be fixed by setting the deretraction setting to 5mm/s so I tried that on a small test piece. The photos feature the issue at hand.

PS: Thinking that this might be an issue linked to the layer height, I'm reprinting as we speak with a 0.35 layer height

Thanks for reading me, been a long time lurker here and have always come to this place for knowledgeable folks

L

Fillament is an all new spool of Natural PLA from Fillamentum

RE: Z seam issues on thin wall prints

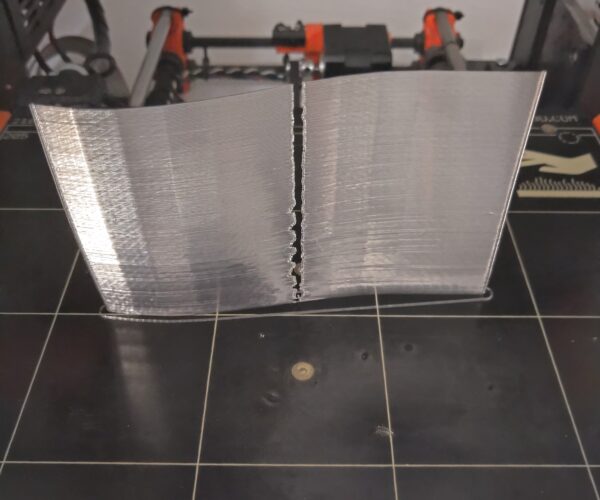

This is the same print at 0.3 layer height,

For some reason on this print the Z-seam painting didn't function

I've just launched a print without the deretraction setting to see if anything would change and had to stop the print because i could see that the results were the same

Slicer has no room to hide it's manipulations, use a smaller nozzle.

Cherio,

RE: Z seam issues on thin wall prints

Thank you for your answer,

I'm not sure I quite understand what you mean would you mind explaining a little bit more?

Thanks again

A 0.4mm nozzle will generally be used at 0.45mm extrusion width at no more than 0.2mm layer height. Your walls require the extrusion to be reduced slightly even to fit in a single extrusion and while 0.15 mm layers will be close to optimum for strength 0.35 will be fragile.

Because you have only one, reduced, extrusion thick any variation in output has to take place in the outer (on both sides) layer. With the more reliable plan of using two perimeters and allowing a little space between them for the slicer to insert variable width layer(s) you are looking at neat surfaces being attainable with a 0.4mm nozzle above 2mm thick walls.

If you want neat, thin walls without using vase mode then change to a smaller nozzle and a layer height no more than half the nozzle diameter.

Cheerio,

RE: Z seam issues on thin wall prints

Thank you for this detailed answer, makes a lot of sense!