Re: Simplify3D print settings (August 30, 2016)

Please give my new profile for MK2

Thanks

Re: Simplify3D print settings (August 30, 2016)

Please give my new profile for MK2

Thanks

Try the attached one.

Re: Simplify3D print settings (August 30, 2016)

Please give my new profile for MK2

Thanks

Try the attached one.

Thank you very much for that. I used those settings and with a bit higher multiplier (1.04) and it made the best print so far. I am curious where you got those settings- is it from your personal trial and error?

The settings in the original post by Josef Prusa are quite different and the print did not come out nearly as good.

Re: Simplify3D print settings (August 30, 2016)

I am curious where you got those settings- is it from your personal trial and error?

The settings in the original post by Josef Prusa are quite different and the print did not come out nearly as good.

Thank you for that praise, you make me blush. 😳

To be honest, those settings are indeed the ones from the first page , basically.

I certainly did some adjustments for my needs and filaments. ( by some experience, and, yes, trial and error...)

Changes for auto-configuration in the .fff manually.

Minor tweaking at the max acceleration settings in the post script field.

Major changes by my doing are...

- Drawing the purge line at the front of the bed.

- Lifting the nozzle after height calibration for two seconds for nozzle (and bed) cleaning.

- forcing the fan to PWM 255 (full speed) over PWM 210 which lets me use the variable fan speed function

of S3D which originally is calculated somewhat odd. (never goes full speed for there never will be a zero layer-time)

Biggest improvement in my opinion is the Lin-Advance function which is implemented for each of my materials.

(Filaflex might need some further tweaking,though...)

Happy you could make good use of it!

It at least may be a good start for you to begin tweaking for your materials...

Have fun and success!

Re: Simplify3D print settings (August 30, 2016)

Hello, I am sorry if this question has been asked twice, I have switched from the prusa i3 mk2 to the prusa i3 mk2 MM. I have been using Simplify 3d for over a year now and have been very happy with it. However after switching to the Multi Material upgrade, I have had to switch back to Slic3r to ensure the printer prints correctly and works with the new setup. I have been successful with Slic3r but would still like to use Simplify 3d as i like the layout of the program and its ease of use. It also helps with approximate time of print which Slic3r does not do. Is there a newly updated simplify3d settings for the Multi Material. Even just the single head setting would be fine. Ill use the slic3r program when doing Multi Material prints. Thank you very much for any help you can provide!

Printer- Prusa i3 mk2-X-MM 😀

-Mike

Re: Simplify3D print settings (August 30, 2016)

Will there be a “official’ MK3 profile?

New to this, and reading the thread for tidbits of info and direction now.

Will a MK2S profile be ~correct?

Or are there some important considerations that are perhaps omitted from being compatible?

Re: Simplify3D print settings (August 30, 2016)

trying your PLA settings and same experience so far.. picked a stupidly detailed vase to print and the speeds and precision are spot on so far.. except i changed fan speed to 100% ,cause i have a fan that only runs 0 or 100% till new one arrives next week, and it didn't turn on at all , had to manually turn it on in the pane.. but otherwise awesome.. I have a dozen filaments that I need to work with but as most of them just replicate the ABS settings which aren't far from PETG apart from bed n extruder temps I think i'll use yours as a base.. makes way more sense to me to only have the layer heights and perimeters etc in the <autoconfigurequality> bits and EVERYTHING else on a per material basis.. has always irritated the hell out of me to change materials and start printing only to realise I'm getting stringing cause i forgot to change the retraction settings.. far better to repeat them all per material.. I like the lift head at beginning too to allow nozzle cleaning, good move

spent a couple of hours comparing your FFF file numbers to mine and couple of questions.. retraction zlift you have set to zero, mine is at 0.5.. incidentally i'm using slightly adjusted versions of mateo2's files from earlier in this thread.. is the lack of zlift something that changed with the new linear advance? or something that you had set that way before?

and speeds.. I've not tried your filaflex settings yet ( vase still printing) but usually flex filament is printed way way slower than PLA or say PETG.. in your setup the speeds are entirely quality dependent, and thus the same for every material unless you change layer heights/quality... does this actually work? I can't imagine printing flex at the speed this PLA print is going at the moment?

[/quote]

Thank you for that praise, you make me blush. 😳

To be honest, those settings are indeed the ones from the first page , basically.

I certainly did some adjustments for my needs and filaments. ( by some experience, and, yes, trial and error...)

Changes for auto-configuration in the .fff manually.

Minor tweaking at the max acceleration settings in the post script field.

Major changes by my doing are...

- Drawing the purge line at the front of the bed.

- Lifting the nozzle after height calibration for two seconds for nozzle (and bed) cleaning.

- forcing the fan to PWM 255 (full speed) over PWM 210 which lets me use the variable fan speed function

of S3D which originally is calculated somewhat odd. (never goes full speed for there never will be a zero layer-time)

Biggest improvement in my opinion is the Lin-Advance function which is implemented for each of my materials.

(Filaflex might need some further tweaking,though...)

Happy you could make good use of it!

It at least may be a good start for you to begin tweaking for your materials...

Have fun and success!

[/quote]

Re: Simplify3D print settings (August 30, 2016)

I like the lift head at beginning too to allow nozzle cleaning, good move

Happy to hear that! 😀

spent a couple of hours comparing your FFF file numbers to mine and couple of questions.. retraction zlift you have set to zero, mine is at 0.5.. incidentally i'm using slightly adjusted versions of mateo2's files from earlier in this thread.. is the lack of zlift something that changed with the new linear advance? or something that you had set that way before?

and speeds.. I've not tried your filaflex settings yet ( vase still printing) but usually flex filament is printed way way slower than PLA or say PETG.. in your setup the speeds are entirely quality dependent, and thus the same for every material unless you change layer heights/quality... does this actually work? I can't imagine printing flex at the speed this PLA print is going at the moment?

I never used zlift and never thought anything about at the beginning.

Initially I have been with Makerware for my former CTC where it was not used by default and I kept it so with my Prusa.

I think with wrong settings and thus a say "Marvin" curling its ass upwards no reasonable zlift would be of help, anyway.

I seem to remember that I read somewhere that zlift is often used for deltas but not so neccessary with cartesians.

In my opinion it often is used just to compensate otherwise wrong settings as too high multipliers e.g.

With the flex material you are certainly right.

I certainly tried to get that in the .fff too, but had to learn, that it kind of messes up all my others.

I do not use it often and make those two settings manually.

I onlyprint it with 0,2mm layer height at 40mm/sec which is the absolut max (for my setup and material).

Even with infill every two layers the feed is to much and it gets stuck....

The spring tension on the idler VERY loose, just so that it touches and could barely pulled out with two fingers...

Re: Simplify3D print settings (August 30, 2016)

yeah I think I might move the speed into autoconfigure materials too.. frankly i print everything at 0.2mm height anyway.. I'm getting such good results at that height I rarely see the need to go lower.. as its so rare to change I'd rather have my day to day settings ALL per material and then IF I change the layer height I know to manually tweak a couple of other settings beyond the top/bottom and perimeter settings.. otherwise swap material and every setting is automatically set.. the only thing to change depending on the actual article being printed is infill % and the new better thinwall settings which should still be in the advanced tab anyway..

stuff to play around with over christmas.. I'll print some test cubes once this vase is finished and ramp up the speeds and try some stuff..

Re: Simplify3D print settings (August 30, 2016)

Will there be a “official’ MK3 profile?

New to this, and reading the thread for tidbits of info and direction now.

Will a MK2S profile be ~correct?

Or are there some important considerations that are perhaps omitted from being compatible?

+1 this

I'm new to Prusa i3 and wondering where to find Simplify3D for my newly built mk3. Has anyone made one yet or should I make one based on this mk2 profile and the mk3 Slic3r profile?

Re: Simplify3D print settings (August 30, 2016)

Having made some maintenance on my printer during my holidays,

- mostly new bearings and braces for the y-axis and replacing the PEI sheet -

I also made some adjustments in my FFF profiles which earn me some quite decent prints.

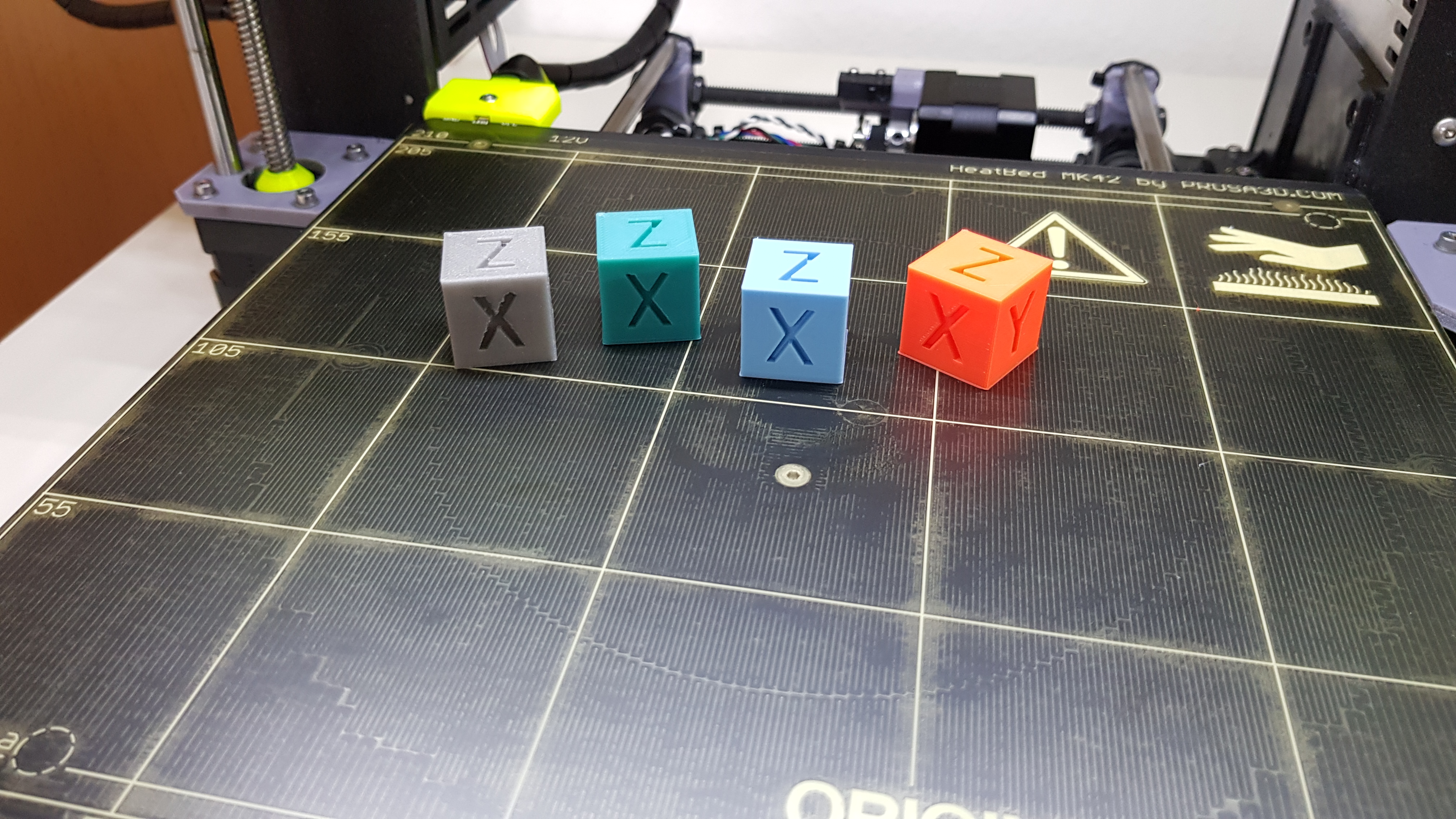

grey - Filaflex / green - PETG / blue - EU-Makers PLA / orange - standard PLA

And don`t you say anything, I know, my live-z- height for 1st layer may be a little to tight... 😳

Although there certainly are some who can do that way better than me I nonetheless would like

to share this profile which hopefully might be of help or at least a good one to begin with for further development.

It is based on the one in the first post here provided (thank you for that!) and I did some

changes for my setup and personal needs and preferences. (I3 MK2S / 2 different PLAs / Filaflex / PETG/ no ABS, sorry)

basic settings

- most of the autoconfiguration settings are with the material, just the speed is with the quality settings.

start script

- purge line at the front of the bed

- lifting the tool 6cm after bed leveling for 3 seconds for nozzle cleaning

- added some "beeps" for the above mentioned actions

- added Lin-Advanced commands for all materials (PLA 30 / PETG 45 / Filaflex 70)

- reduced the travel acceleration somewhat

(I still thought some jerks at smaller parts being to heavy but would not want to reduce the whole travel-speed for ooze on bigger ones)

end script

- lifting the tool 2mm before homing for not to scratch the surface (happened sometimes)

- lifting the tool to absolut 10cm after homing for better accessability

Attention! For parts higher than 10 cm at the left one would have to check carefully whether it would be better not be used.

After homing the tool will be lowered and may crash in the part!

- added a beep at end of all actions.

post processing scripts

- minor adjustments to the acceleration settings (inner/outer perimeter /infill ...) as provided here in the 1st post to my likings.

- increasing the usability of fan-auto-speed by forcing the fan to full speed (PWM 255) when exeeding a certain value ( PWM 210 )

( S3D seems to calculate it by spreading the speed between the determined minimum layer time and zero seconds. For there

is no zero layer time the fan never goes full speed)

Additional remarks

- print speed for Filaflex 30mm/sec is to be set manually (it would mess up all my othe autoconfigs and I use it rarely)

- S3D 4.0.1 which has one little bug as far as I know, "start point at specific location" works only with

"print islands sequentially without optimization" UNCHECKED.

- I have two PLA profiles, the standard should be ok for most purposes. The EU-Makers profile needs the multiplier upped a bit.

- the bridging capabilities of my specific PETG seem to be nearly not existing at all, so here maybe one would need to do further tweaking.

Impooved parts for the printer could be found here. https://www.thingiverse.com/blackbird2016/designs

I hope some could make good use of it...

Have fun and success!

Re: Simplify3D print settings (August 30, 2016)

Having made some maintenance on my printer during my holidays...

Thank you very much for the update 🙂

Best regards, Peter

Best regards, Peter

Re: Simplify3D print settings (August 30, 2016)

Hey guys, so I've been doing a TON of tests with .2mm layer height and seams with blobs. I've tried adjusting the restart retraction setting, various settings for coasting and wiping. The best thing I found was putting .2mm layer height to outside in for perimeters. For some reason it is set to inside out in the attached FFF. Setting a restart retraction of -.1 or -.2mm helps a lot if you really want to do inside out, but I would just change it.

The second thing I learned is that .2mm just sucks in general. It's not good. Yea it takes a lot long, but the quality of print at .1mm is phenomenally better. Not just based on layer height either. Comparatively, the seams are near flawless on .1, as opposed to the .2mm layer heights.

The .2 seams seem to be the worst when you print oval objects, or even round objects. Although oval objects seem worse for me? But yea, I would recommend changing the .2 setting for PLA to outside in and you will see much better results. The seam will still be there, and on some layers you might see a slight blob, nothing serious, but it's a lot better. Also, on .2mm, setting a seam location helps a lot to hide it, if you really need the print speed of .2mm.

I'm by no means a pro, but I did massive amounts of searching and settings to try and solve this issue for .2mm, and frankly, the misinformation out there is staggering. I'm convinced that getting rid of seams at .2mm just isn't possible, and the outside in will cover the slight blobs that occur with the base settings attached here.

Re: Simplify3D print settings (August 30, 2016)

- the bridging capabilities of my specific PETG seem to be nearly not existing at all, so here maybe one would need to do further tweaking.

Well, I used the same PETG Filament from 3DPSP.de for this 150mm Bridging Test.

In your Profile I only set Extra inflation distance to 0, Bridging extrusion multiplier to 85% and Bridging speed to 100% in S3D.

Modifications: -your fan nozzle from thingiverse, this intake https://www.thingiverse.com/thing:2718992 and a silicon sock from E3D.

The Bridging Test was surprisingly good in my opinion, 😎

Re: Simplify3D print settings (August 30, 2016)

In your Profile I only set Extra inflation distance to 0, Bridging extrusion multiplier to 85% and Bridging speed to 100% in S3D.

Modifications: -your fan nozzle from thingiverse, this intake https://www.thingiverse.com/thing:2718992 and a silicon sock from E3D.

The Bridging Test was surprisingly good in my opinion, 😎

Thank you for using my fan duct 🙂 and happy printing.

You certainly are right, my settings for bridging were wrong, plain and simply.

No idea how I came to make the extra inflation to 1,5 mm.... (the 3rd beer maybe)

And still, I meanwhile changed my nozzle which had some wear and now the bridgings are way better.

Very interesting, although the wear did not show that much at the surfaces or walls it affects the bridges way more than I would have expected.

Sorry to all who already downloaded my profile from here https://shop.prusa3d.com/forum/posting.php?f=23&mode=quote&p=60350&sid=2c56f301a3e70c9bae0cc5beb039d92d#pr57617

Attached is the new one with different settings for bridging.

I meanwhile also made some changes in the start script including M907 commands. (motor current)

Slightly reduced high power settings for bed leveling.

Slightly increased silent mode power for the print.

Could certainly be changed to ones desired values, and still will be overriden when changing the power mode via display midprint.

Happy printing to you all...

Re: Simplify3D print settings (August 30, 2016)

Just loaded your latest profile, and I noticed that the default printing speed for all materials is 50 mm/s, which seems very slow. Is that intentional? I've been printing at 100+ and getting good results.

Re: Simplify3D print settings (August 30, 2016)

Just loaded your latest profile, and I noticed that the default printing speed for all materials is 50 mm/s, which seems very slow. Is that intentional? I've been printing at 100+ and getting good results.

That may depend on what one considers "good results"...

The printing speed in my povided profile is with the quality settings and not with the materials.

I seem to remember 60mm/sec with 0,2mm layer height.

You still could change it to your needs.

Depending on what you are printing 100mm/sec could be a very good setting or just otherwise insane fast.

Basically printing speed is not my 1st priority....

I am pretty sure, the following could not be done with those fast 100mm/sec....

Re: Simplify3D print settings (August 30, 2016)

Beautiful prints!

Yeah, speed and quality is a tradeoff. I usually push the infill as fast as possible, then the outer layer slow. I print (in S3D) speed 100 mm/s, then "outline underspeed" of 50%, so the outermost shell ends up, interestingly enough, the same speed as your profile! 😀

Re: Simplify3D print settings (August 30, 2016)

Alexander, I have still one question. Why is your layerwidth 0,4mm?

I have set it on auto (0,48mm) and my prints turned out as good as with the 0,4mm setting plus better layerbonding.

Re: Simplify3D print settings (August 30, 2016)

Alexander, I have still one question. Why is your layerwidth 0,4mm?

I have set it on auto (0,48mm) and my prints turned out as good as with the 0,4mm setting plus better layerbonding.

Reason is that either the Prusa-profile that came with S3D and the one provided here on the 1st page both are with manual diameter. Never had any issues with layer bonding.

Certainly I do not claim my profile to be the one and only....

It just may be a good one to start with.