Problem with DEVILS DESIGN filament

My printer is Original Prusa i3 MK2 kit assembly v1.06.

I had gray PRUSA PLA filament and I didnt had any problems with it. This orange filament is also PLA and have same specifications as PRUSA filament. But when I want to print something weird happens. Something like after 40th layer , filament won stick on previous layer and thats where printing misbehave.

I print very good this small parts on pictures , but I dont know why on 50% of large printings wont print good like first 50%.

My temperature is very good , everything is okay , even I recalibrate PID and do selftest so this factors doesnt affect bad printing

Re: Problem with DEVILS DESIGN filament

Is the part one shell before you slice it? What slicer are you using??

Re: Problem with DEVILS DESIGN filament

My guess would be to raise the nozzle temp and slow down the print. Default 200mm/s is for most filaments an issue.

Bigget parts -> Faster extrusion

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Problem with DEVILS DESIGN filament

Is the part one shell before you slice it? What slicer are you using??

Yes , that seperate things should be in one piece , but obviously after 40% of print , layer wont stick well on previous layer.

I use Slic3r PE 1.41.3, latest update..

Re: Problem with DEVILS DESIGN filament

My guess would be to raise the nozzle temp and slow down the print. Default 200mm/s is for most filaments an issue.

Bigget parts -> Faster extrusion

I will try with that method , but just to say , this small parts on pictures that are good , in the begining I tried to print on 80% speed and happened like this large print. And then I set speed on 100% and small parts turned out very good like this on pictures. So I thought maybe I need print large prints on 100% speed like on small ones , and first 40% was good and then I thought everything will work out, I left 3D printer and when I came back after 30 minutes , I saw this on printer ------ what should be in one piece.

Re: Problem with DEVILS DESIGN filament

This most likely is not material related. Did you swap back to the Prusa filament checking whether this still happens?

This happening always at around the same height, it could be a bad connecton/broken cable which either cause

a temperature drop or temperature misreading.

The pictures look like a massive underextrusion, though.

If this happend to me, I would try to find the cause by sitting in front of my printer observing carefully what is when happening.

Re: Problem with DEVILS DESIGN filament

I think you said the part has multiple shells. Can you upload your stl of the part ?

Re: Problem with DEVILS DESIGN filament

I think you said the part has multiple shells. Can you upload your stl of the part ?

Here is STL file of that part

Re: Problem with DEVILS DESIGN filament

I would be looking for mechanical issues rather than slicer issues.

First things i would check is your filament spool can rotate freely.

Ensure your screws that press the filament into the hobbed gear are adjusted correctly. To tight is just as bad as to loose so set just as the manual says.

Make sure your filament is not wound badly. It can snag on itself and cause issues like what you are seeing.

As has already been suggested you may have a damaged wire that only fails at a certain position.

Re: Problem with DEVILS DESIGN filament

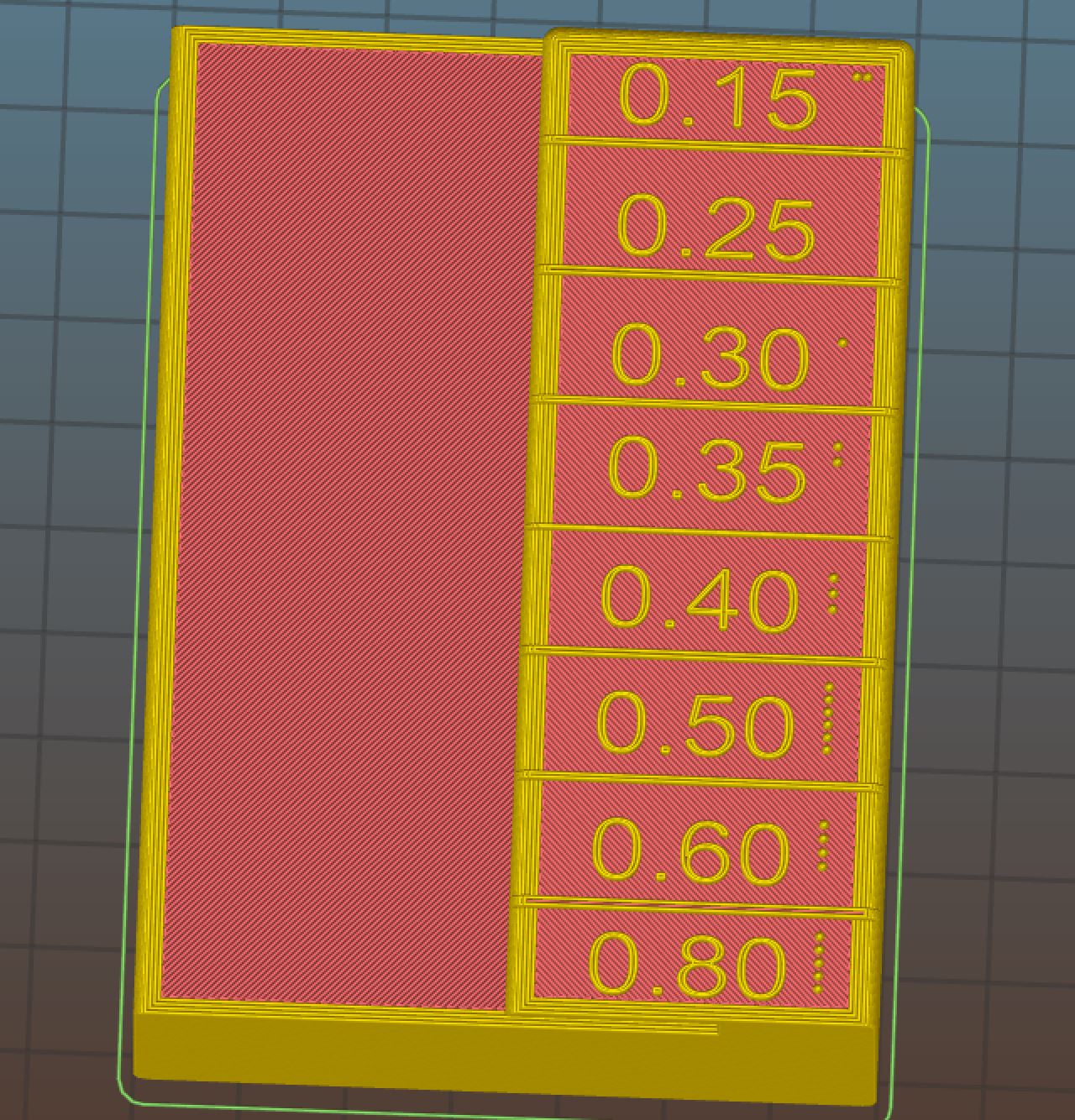

Looking at the model, there's only one place I see a potential of print issues (highlighted below). But I'd rate them as minimal risk and the images you've posted show a different issue.

The broken wire theory fits, so does a nozzle plug.

I've personally seen plugs that go away then come back many layers into a new print and repeat that way. Cold pulls didn't help, either. I had to remove the nozzle, and blast canned air up through the extruder to clean out a bunch of filament dust that had collected in the heat break; the fountain of dust that came out surprised me, wish I had a video. My guess is the dust rattled around for a while then fell against the good filament until it all wedged in and jammed it. I now clean the PFTE with canned air every few prints, just in case.