First layer Trouble

Typical NOOb q.

I'm struggling with the settings on my Prusa Mk2 with Sli3r and RIGID ink PETG. I also have an enclosure and am using glue stick.

I can't get the first layer to go down right. The nozzle oozes a bit during the warm up. The Brim layer seems to go a bit too quick and doesn't tend to stick at the start of the run. It's like the nozzle is more sticky than the bed. The perimeter doesn't always go down if the direction change is too quick and as you can see from the photo the first fill layer clumps up as it doubles back. I've played around with different setting but feel like I'm stabbing in the dark. Please help:

Here is a list of my some of my current settings:

1st Layer bed temp: 75

1st Layer nozzle temp: 210

Previous nozzle Z was: -0.650 Currently: -0.475

Retraction: 2mm

Retraction speed: 25mm/s

I have a schedule of every setting I use so let me know if you need to know anything else. Thanks in advance.

Tony

Re: First layer Trouble

Hi Tonyptah,

are you using the latest Slic3r prusa edition?

My mk2 has a multi material unit on it, so the settings are a bit different to normal

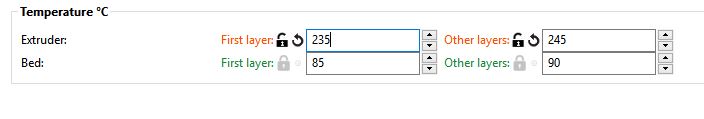

on my Mk3 I use the generic PETG Profile which uses the following temperatures

rigid ink suggest different temperatures

but they all look higher than yours...

I prefer to go slowly on the first layer 15mm/s

do you need 2mm retraction. I use 0.8mm

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: First layer Trouble

I have just dialled in for PETG and launched a print. Surprisingly I found live-z same as PLA. I also found a very narrow heatband based on a temperature tower test I ran. First later 225/75, remainder 220/80 spool is marked as 210 to 230 extruder.

Windex sprayed directly on the bed, spread evenly with a paper towel and left to dry.

Bill

Tagaytay City, Philippines

Founder member of Philippines Prusa Printer Owners FB Group

Sponsor Pillars of God Academy in Bacoor

Re: First layer Trouble

Righty guys, based off your kind suggestions:

Attempt - 1

1st Layer bed temp: 75 to 85

1st Layer nozzle temp: 210 to 235

Previous nozzle Z: -0.475

Retraction: 2mm

Retraction speed: 25mm/s

Perimeter: 30 to 15

External perimeter: 30 to 15

This shows definite improvements but the material was still being dragged. decided to alter Live Z to previous ASA filament settings of -0.650

Attempt - 2

1st Layer bed temp: 85

1st Layer nozzle temp: 235

Previous nozzle Z: -0.650

Retraction: 2mm

Retraction speed: 25mm/s

Perimeter: 30 to 15

External perimeter: 30 to 15

I put a bit more glue stick on the problem area but as you can see its still smears excess material as it doubles back which in this case turned into a blob. You can see "strings" all across the surface. What next guys??

Re: First layer Trouble

See my post "Not All Glue Sticks are Created Equal" https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/not-all-glue-sticks-are-created-equal-t24236.html

I was having the same kind of problem as the OP when using the glue stick that came with the kit, but Scotch Craft Stick solved the problem.

Re: First layer Trouble

Just tried another go but backed off the Live Z to -0.575. This seems to have helped reduce the dragging and I nearly got some sort of complete 1st layer.....until the lump of excess filament that again built up on the nozzle dropped off. GRRRR.

RetireeJay makes a good point about glue sticks but I don't appear to have that problem. To me it looks like excess material?

Could I I solve this by lowering the extrusion multiplier from 1 to 0.95? My reason for asking instead of trying is that I don't want to start messing about with settings that you guys haven't had too. I'll end up over complicating the issue.

Re: First layer Trouble

Decided to lower the extrusion multiplier anyway from 1 to 0.95. (I know I'm impatient). Had to nip out to get Special with Seasonal Vegetables and Salt and Pepper chips but came back to a much better looking 1st layer (missed photo op). This print has quite a big surface area so no idea how the multiplier will affect things. Never messed with it before.

Hopefully this will help someone else.

Ps: If this was the wrong setting to change please let me know. Thanks again.

Re: First layer Trouble

It looks like maybe your nozzle is too low, creating the "plowed field" effect where plastic gets squeezed out and up on either side of the actual trace. In effect, there's too much plastic being extruded relative to the thickness of the first layer, and it's got to go somewhere so it ends up creating those ridges and sandpapery peaks. The solution to that is to reduce the amount of Z offset. Since Z offset is a negative number, that means making it less negative. You can "live adjust" the Z offset while doing this print, and once you get a good value, the printer will remember it.

You can learn a lot by using a first-layer calibration routine, either the one built-in to the firmware or the one that Joan T mentioned. The problem with the first-layer calibration routine built into the firmware is that it pretty much insists on using PLA, which is inconvenient if you have PETG loaded in the extruder. (I have submitted a request on GitHub for the developers to change that, but it's been ignored for many weeks now.)

When you have a first-layer over extrusion problem, reducing your Extrusion Multiplier is the wrong answer because it affects every layer throughout the whole print. The only correct answer is to change the Z height so that the first layer isn't over-extruding.

Re: First layer Trouble

I think there may be a bit of confusion here

The first layer can suffer from over extrusion. And it can suffer from the extruder being too low. In fact it can suffer from both at the same time...

Both look the same on the fi8rst layer. Because you are trying to inject too much molten plastic into too small a place...

Reducing the extrusion multiplier if you are not actually over extrusion can result in a thinner than expected first layer. And underextruded upper layers.

I have found that it is best. To start with an extrusion multiplier of 1 then address the first layer by adjusting live Z on its own to begin with.

Then when you have the perfect first layer

Look at succeeding layers.

If they have the ploughed field look. Then. And only then. Reduce the extrusion multiplier

Now reducing the extrusion multiplier affects all layers. So this May require your first layer live Z to be lowered a tiny bit... However following that Re adjustment all layers should be good.

The problem is. If you change a number of things at the same time. You can get into a heap of bother...

PETG seems to like building up on the nozzle. So over extrusion is a bad thing...

A little under extrusion is less problematic.

Let us know how your model turns out

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK