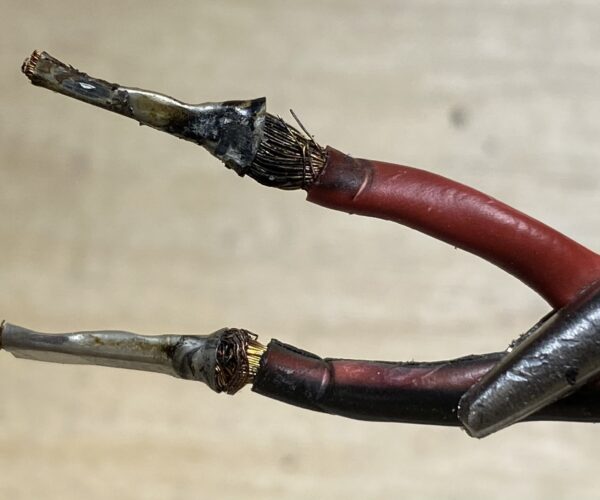

RE: Burned wires, Melted plastic

hey @grandpa-joe,

I had this problem 2 times in about 3 weeks probably because the strain relief of my heatbed-cable wasn't done proper by me. After this, I soldered the wires directly to the mainboard and since then, I never had any issues. (and I 've made the strain relief correctly)

RE: Burned wires, Melted plastic

Thanks. I ended up with a new circuit board and a new heat bed.

RE: Burned wires, Melted plastic

Just be careful and try to avoid what caused it. This could result in a fire. I burned up one controller board.

--------------------

Chuck H

3D Printer Review Blog

RE: Burned wires, Melted plastic

I ran into this problem on my upgraded mk2.5s after many years of printing, a couple of the molex connectors started to melt.

These are the part numbers for replacements:

Had no issues desoldering in the replacement board connectors, GND terminals will need quite a bit more time to heat with the soldering iron.

Cut back the wires till the copper is fresh again and crimp a suitable sized ferrule on if you already have one of the crimper tools.

Been running the printer for nearly a year since I had to install the replacements, will know to keep an eye on the terminals more often to check for signs of melting.

RE: Burned wires, Melted plastic

I review your pictures again. You must have had a loose screw on the terminal connector or bad solder on the board. To heat up like that it must have had significant resistance.

--------------------

Chuck H

3D Printer Review Blog

RE: Burned wires, Melted plastic

@cwbullet

Thanks. I went ahead and replaced the heat bed.

RE: Burned wires, Melted plastic

@grandpa-joe

I am pretty sure that is best.

--------------------

Chuck H

3D Printer Review Blog

Old parts are the problem

I had this problem also just this week. I think it’s likely that the wiring was impacted by repeated movement creating a looser connection. I found the mk2 rambo box does not secure the heat bed wiring with the newer mk2.5s wire covers. The old wire covers were thick plastic and the new ones are thinner plastic felt.

I review your pictures again. You must have had a loose screw on the terminal connector or bad solder on the board. To heat up like that it must have had significant resistance.

in my old MK2 i soldered everything, both on bed and rambo 🙂

but i did it only because ready to replace them

I'm not an expert. Ma parlo anche italiano 😉

Soldering

I am not a pro at soldering and it always worries me that my efforts will create too much resistance.

in my old MK2 i soldered everything, both on bed and rambo 🙂

but i did it only because ready to replace them

--------------------

Chuck H

3D Printer Review Blog

Solder!

It was a loose connection, eventually also causing this...

Hypothesis; since the terminals on the heatbed are bolted and not soldered, the bolt came slightly loose, created more resistance, melted the rambo and a created a short.

I've soldered the heatbed connections and also think that solves part of the issue.

RE: Burned wires, Melted plastic

After 3 years of printing I had the same issue. In my case it was caused by a not perfect crimped cable connector inside the PSU (power supply unit). after fixing the cable and installation of a new moldex connector on the board the printer worked again

RE: Burned wires, Melted plastic

Yup. I have had this also. I check my terminal screws once a month.

--------------------

Chuck H

3D Printer Review Blog

RE:

I discovered this issue today, contact area became minimal due to the nylock nut and bolt getting loose on the positive terminal and almost loose on the negative.

I think this was due to thermal and mechanical cycling since when I started using PETG, heating the bed to 85C. When doing TPU and PLA clearly this issue would either go unnoticed or be non-existent.

Considering the hazard involved, I'll be checking the cable cover for overheating when starting each print and the bolts every few tens of hours of printing time.