Re: New printed parts B7/R3 and other improvements for the MK3

Hello all,

Just had a failed unload. The withdrawing filament got pushed into the inspection whole and curled damaging the filament sensor. Could you please remove the inspection whole in the next iteration of the parts.

Regards,

Martin

Martin Wolfe

Re: New printed parts B7/R3 and other improvements for the MK3

Hello all,

Just had a failed unload. The withdrawing filament got pushed into the inspection whole and curled damaging the filament sensor. Could you please remove the inspection whole in the next iteration of the parts.

Regards,

Martin

Martin how did that happen, I thought you had to pull on the filament when unloading, that is what I do, did you pull or just let it unload alone, just for info.......... 💡 💡

Re: New printed parts B7/R3 and other improvements for the MK3

The unload was triggered by the filament sensor at the end of a real. So the top tip of the filament was below the inspection whole but above the bondtech gears when the unload started. As the curve in the filament had not been ironed out as it reversed upwards the tip got caught on the inspection whole causing the filament to bed further and slam into the sensor.

I ended up having to manually pull the filament out with pliers to complete the unload. The good news is once I loaded the new filament the print resumed to completion. 🙂

Regards,

Martin

Martin Wolfe

Re: New printed parts B7/R3 and other improvements for the MK3

The unload was triggered by the filament sensor at the end of a real. So the top tip of the filament was below the inspection whole but above the bondtech gears when the unload started. As the curve in the filament had not been ironed out as it reversed upwards the tip got caught on the inspection whole causing the filament to bed further and slam into the sensor.

I ended up having to manually pull the filament out with pliers to complete the unload. The good news is once I loaded the new filament the print resumed to completion. 🙂

Regards,

Martin

Cheers for that Martin, will keep my eye on that when I decide to change my parts................ 🙂 🙂 🙂 🙂 🙂

Re: New printed parts B7/R3 and other improvements for the MK3

I haven't received my first printer yet (arrives in a few days) but I already have a Raspberry Pi B+ lying around and I plan to use that and a Pi webcam to run Octoprint. How easy would it be to modify the Mk3 case to house that rather than the Zero?

Anyone?

Re: New printed parts B7/R3 and other improvements for the MK3

I haven't received my first printer yet (arrives in a few days) but I already have a Raspberry Pi B+ lying around and I plan to use that and a Pi webcam to run Octoprint. How easy would it be to modify the Mk3 case to house that rather than the Zero?

Anyone?

Simple as below.... 😀 😀 😀 😀 😀

Re: New printed parts B7/R3 and other improvements for the MK3

Hello all,

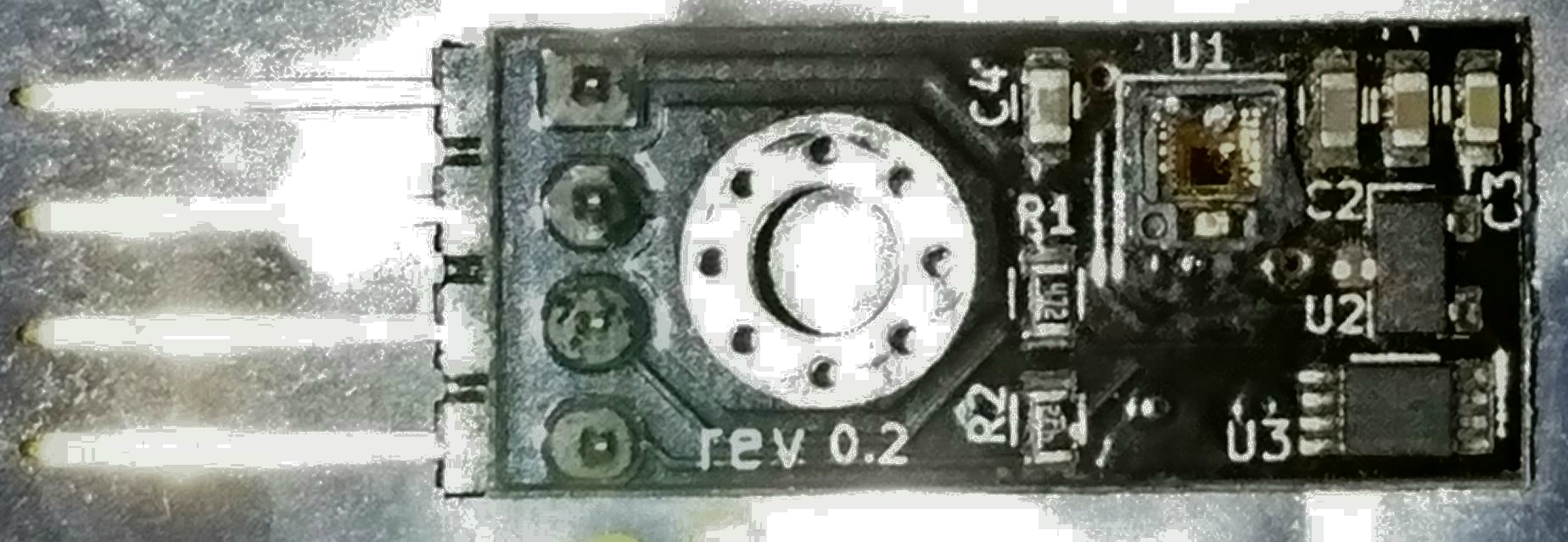

Just a quick follow up to my last post. My new filament sensor arrived today and is now fitted. It is rev0.2e as against my old one which was rev 0.2. The damage is quite visible in the photo below.

In a few days I will be changing over to martin_au's indirect filament sensor which should provide me with a permanent fix that prevents filament from ever crashing into the sensor again.

Regards,

Martin

Martin Wolfe

Re: New printed parts B7/R3 and other improvements for the MK3

I haven't received my first printer yet (arrives in a few days) but I already have a Raspberry Pi B+ lying around and I plan to use that and a Pi webcam to run Octoprint. How easy would it be to modify the Mk3 case to house that rather than the Zero?

Anyone?

Simple as below.... 😀 😀 😀 😀 😀

https://www.thingiverse.com/thing:3127643

Great - many thanks.

Re: New printed parts B7/R3 and other improvements for the MK3

Hi everyone,

UPDATE: New parts C1/R4 for the MK3S/MK2.5S/MMU2S are out! More here: https://shop.prusa3d.com/forum/general-discussion-announcements-and-releases-f61/new-printed-parts-c1-r4-mk3s-mk2-5s-mmu2s-t27888.html

/ Knowledge Base

The guy behind Prusa assembly manuals...

Re: New printed parts B7/R3 and other improvements for the MK3

There is an android version of the APP Jakub, 😀 so the instructions to tighten the belts "to a Low tone" is no longer used?... my use of low 'A' at 220 cycles was based on that instruction and the belt tension report for both belts is smack dab in the middle of the desired range for both of them :geek: I just do better with quantifiable instructions hence my use of a torque driver to tension all the bed screws to that same 10 inch pounds which is 1.13 Newton Meters (N·m) I had to guess at that based on the fasteners size and made out of SS and I would have much preferred to have had a hard torque number from Prusa for all the fasteners in Newton Meters (N·m) is fine I can convert to the inch pounds my tool uses... but I guess you don't want folks with limited tool boxes to think they need to buy a bunch of stuff to assemble a printer and it can be done with the tools you provide but tightening nuts with a needle nose pliers well it offends all the mechanics and engineers in my family tree 😉

I was curious about this print and when I made it and tested it it was spot on at 1 Newton Meter (N·m) It seems to be intended for installing e3d nozzles

IMG_0288.jpeg so folks can print their own torque driver 🙂

I haven't received my first printer yet arrives in a few days but I already have a Raspberry Pi B+ lying around and I plan to use that and a Pi webcam to run Octoprint.