Poor PETG adhesion

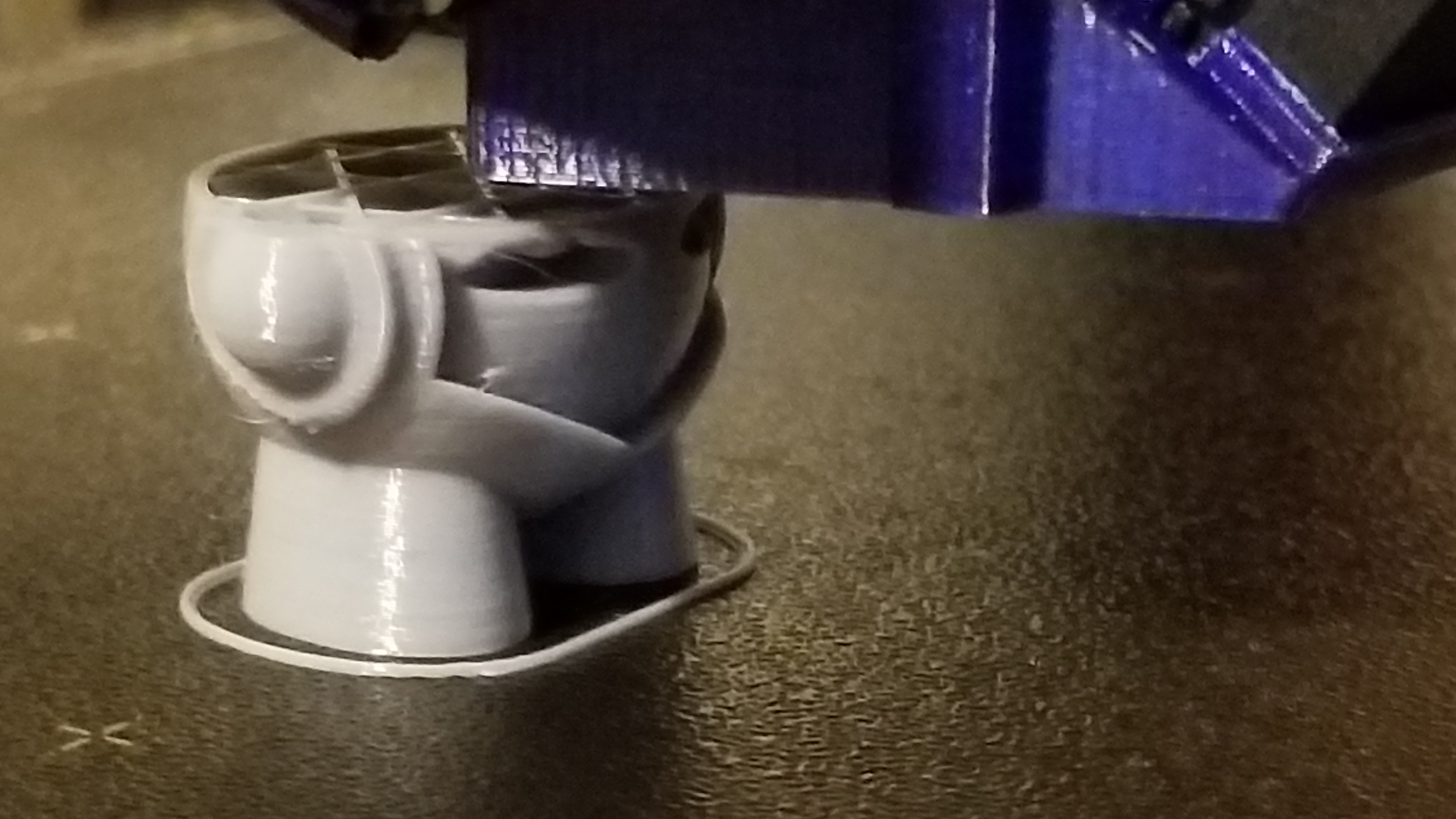

Well, finally got the PETG to stick to the coated build plate but a new problem reared its ugly head. Seems like the infill now has a problem. I am using 255/85 temps and 70% speed with a difference of 0.9z height difference between the PLA and PETG. Have not changed any other settings in the Slic3r PE software. I am using current firmware and Slic3r PE. Can someone point me in the right direction. Any help would be greatly appreciated.

Original Prusa I3 MK2s with 2.5 upgrade; Original Prusa I3 MK3s; Slic3rPE; FreeCAD

Re: Poor PETG adhesion

Hi Andy,

255 seems a bit high for PETG, I usually use 230 for layer 1 and 240 for other layers.

0.9mm difference seems a lot...

try reducing the speeds a little,

Are you using fan from layer 3?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Poor PETG adhesion

It's my opinion Infill speed is too fast for nearly all Prusa settings. The default for PLA is 15 cubic mm per second. My extruder simply can't supply that much plastic that fast. If I use 12 mm^3 /s I get better infill, but still get gaps when there is no plastic. For PLA, 10 mm^3 / s is my printers sweet spot.

I don't print much PET, but the parts I have printed have the exact same issue with infill as PLA. PET infill speeds need to be lowered to about 7.5 mm^3 /s (my experience).

Re: Poor PETG adhesion

Thanks for the reply Joan. But I found the thing that troubled me the most. I had a few issues after the 2.5 upgrade and really thought nothing of them as I was only using PLA at the time other than the Black PETG filament from Prusa for the printed parts for the upgrade. That drove me up the wall. I continued on and was impressed by the write ups about PETG. So I bought 5 spools. Still had PLA left and wanted to use it up before pulling the trigger on PETG. I upgraded to the new extruder update with the slanted fan. A few problems persisted when printing out the PETG parts for the update. A little over a month ago I started into the new PETG. Wanted to throw the 2.5 in the trash, no adhesion to the PEI sheet or the coated sheet. Layers not sticking. Infill flying all over. I was reading in the forum about all of the others that were having similar issues like mine with the filament. I knew if I increased temp the problem lessened. The first few layers were OK, not perfect. When it got to layer 3 the problems really started. That is where the infill started. RETRACTION was the culprit. The new Bowden Gears were not doing the job. Noticed the gear door would not open unless I removed the hinge screw at the top. Something was clogging the nozzle on retraction and return. I changed out the door with the one I took off for the upgrade and low and behold the problems vanished. When the retraction started it drew the filament back into the hot end and nozzle and would clog and miss a layer or two or not feed out in time to adhere the infill layer or spit out a clump that would drag off the printed layer. I feel like a fool not seeing this first but I was counting on the Prusa STL and gcode files to work without issue. I am new to this arena and learning a lot. But not knowing what the door should really look like I put the part in the printer and probably shortened my life with all the headaches I've had over the past month or so. Now I can dial back my temp to get rid of the strings.

Original Prusa I3 MK2s with 2.5 upgrade; Original Prusa I3 MK3s; Slic3rPE; FreeCAD

Re: Poor PETG adhesion

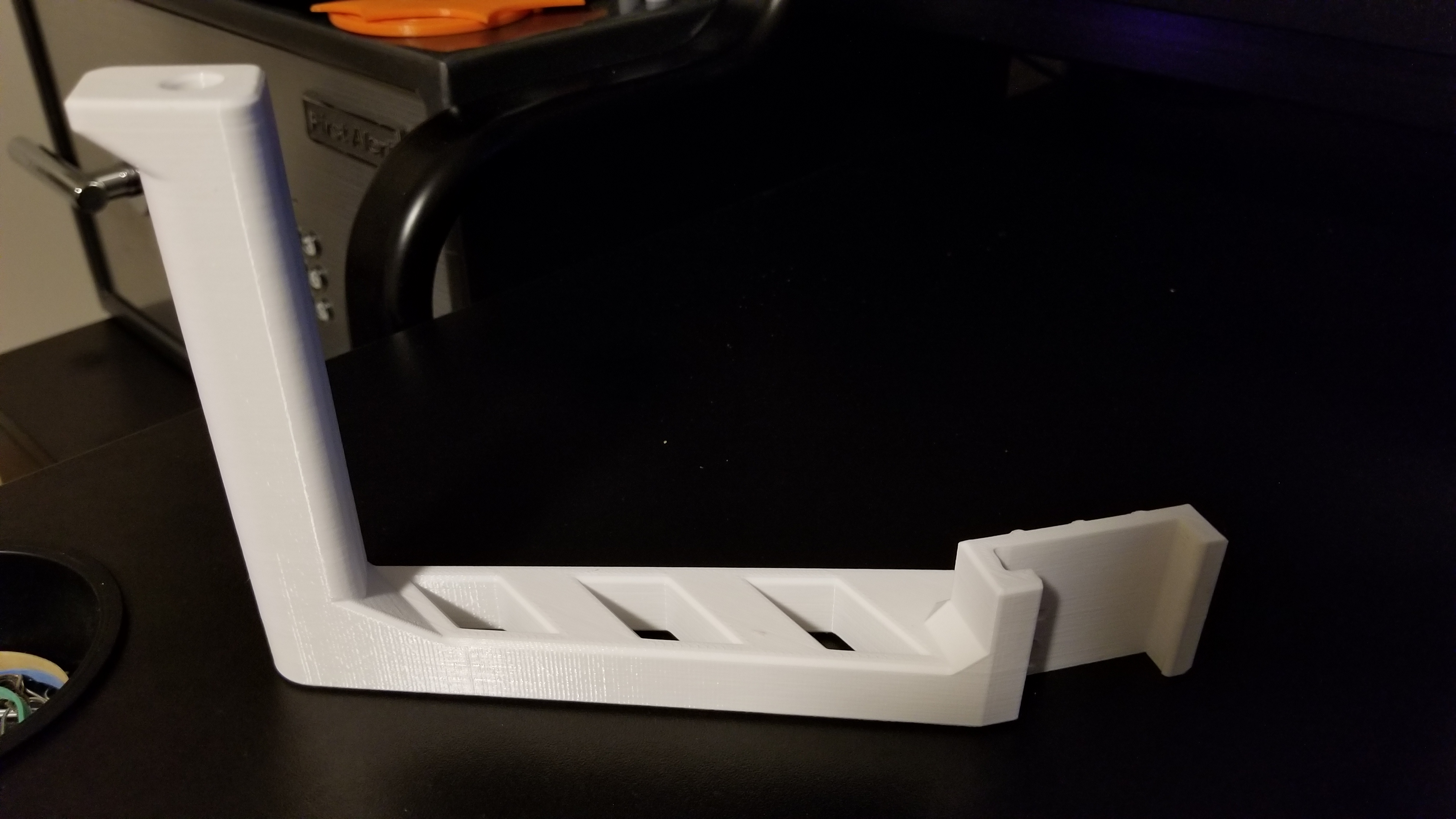

Read your reply Tim. I to thought the same and you can get the same info on Youtube. I played with the speed (down to 70%) and the flow (up to 130) without success. Once I was able to get the filament flowing correctly life was good again. I am doing as Joan suggested by running first layers at 230 and 3rd up 240. I think I will leave the fan alone for now just to see if it improves finish at 240. Did have issues with overhang and strings at 255. The print of Marvin was at 240/90 at full speed with the rest of the settings provided by Slic3r PE. I will try 230/240//85 at full speed to see what happens. At this point I am pleased with the quality, layer adhesion and shine of finished product. Probably will need a few tweaks but should not be too bad.

Original Prusa I3 MK2s with 2.5 upgrade; Original Prusa I3 MK3s; Slic3rPE; FreeCAD

Re: Poor PETG adhesion

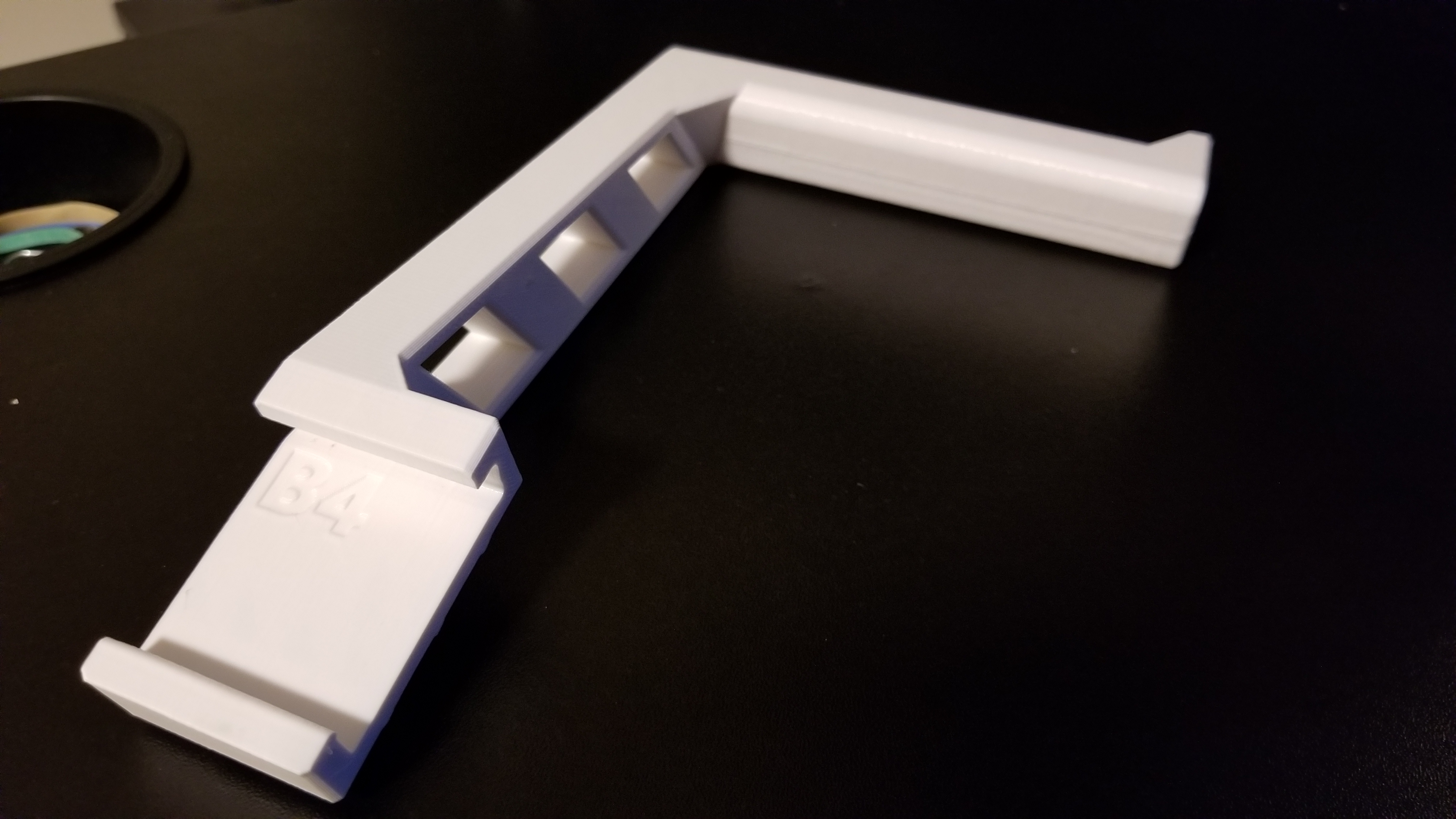

Well, I'm back with good news. The PETG issue is almost resolved. I successfully printed PETG with Slic3r PE settings except temp. I needed to use 250/90 to start first three layers then dialed it back to 240/85. There are no issues including no strings. The print has a very polished look, 45 degree overhang was perfect and almost no layer lines. I have been talking to Prusa about the problem with adhesion on the coated build plate. They are sending me a new one next week that I hope will stick better than the original I have now and I'm hoping that I can dial back the bed temperature to around 80-85 and maybe drop the hot end to 230-235. For what it is worth, I may be a bit hesitant in the future of jumping right in and doing an upgrade or update before a little time passes to see if the process is problem free. The machine worked flawlessly before the 2.5 upgrade and the extruder update but I've learned my lesson the hard way. But, on the positive side, I sure have learned a lot more about filaments, processes, temp characteristics and the disassembly of the 2.5. What an eye opener.

Original Prusa I3 MK2s with 2.5 upgrade; Original Prusa I3 MK3s; Slic3rPE; FreeCAD