Getting started with PETG (on the Mk2.5)

Hi there,

I am using a Mk2 for about half a year now and bought the Mk2.5 upgrade end of April. Since I was printing ABS until now, I wanted to learn to print PETG – but for the last few weeks I am only looking at failed first Layers (despite the very first print, a Benchy, with the Live-Z from ABS). Since then I tried nearly all values around the ABS-Live-Z (+-100), corrected the right side mesh bed leveling to be +50 now (the skirt was stopping on the right, so I raised the bed level correct until it nearly does not anymore, but also I am at the max). This is the first attached image, where the brim gets really squished at the right back side.

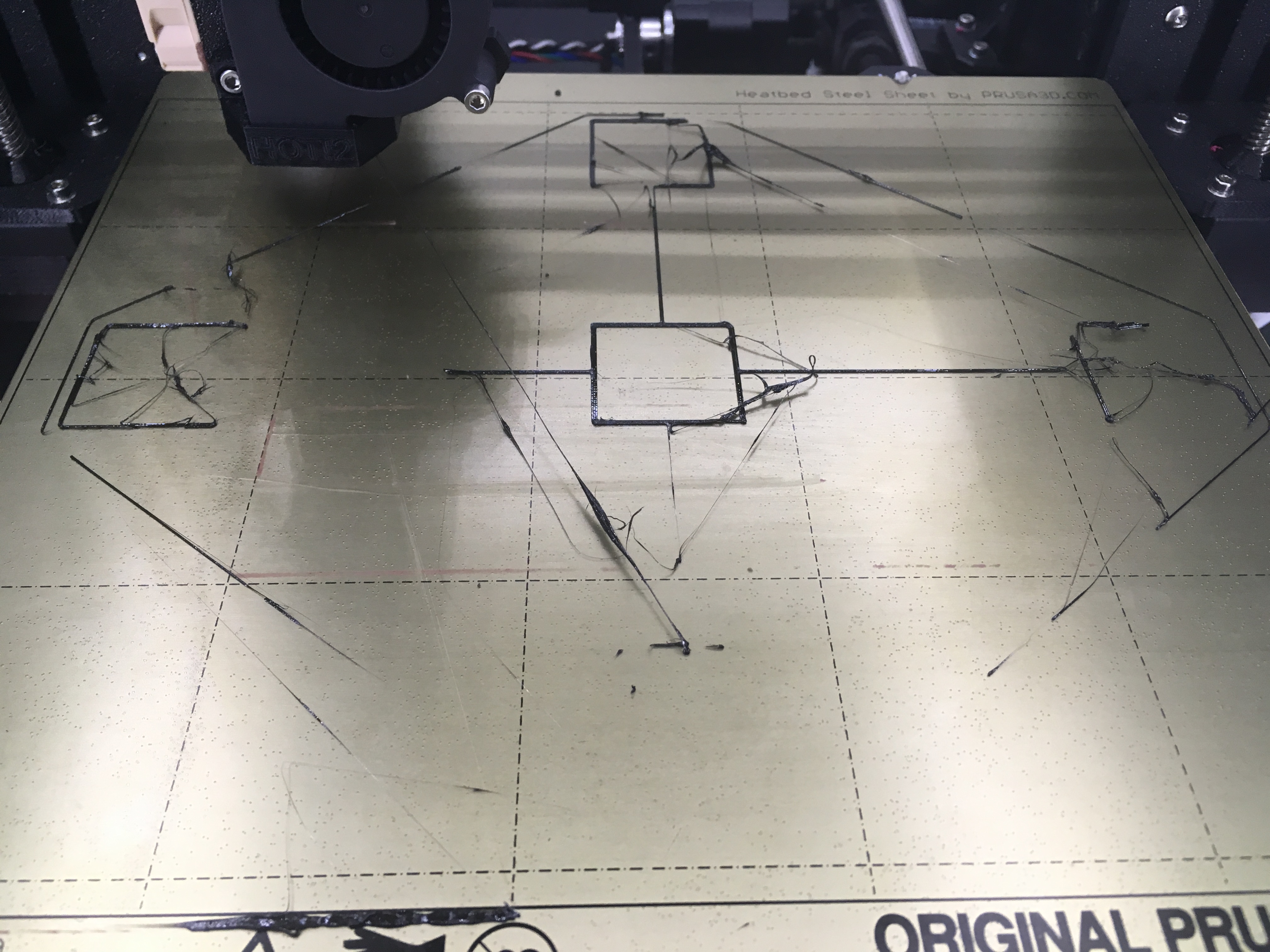

I also tried different temperatures for the original Prusa PETG and a little bit of flow. And – most of all, I looked at the print start with a speed down to 25% to slowly see, where it might fail, which I try to illustrate with the second image, that usually (with ABS) should read S-t-a-c-k-e-n – and I know it's a fine structure, _but_ it worked fine for all my test and prototypes for the last half year with ABS (using the same settings even for the first prints on the Mk2.5).

The problem seems to be that a little bit of PETG catches the nozzle and from than on a small blob smeares the PETG everywhere but not where it should got. And that seems to happen at a random point (sometimes it looks a bit better in the beginning, and as I said, the first Benchy printed well including the text on the bottom) – but I can't figure out why that is happening and it is not happening deterministically.

Any ideas what I can check besides 200nm of Live-Z checked through, temperatures, speed (all from 30% to 100% in 5% steps)? I am really lost in my approach to PETG and running out of ideas. I also tried with glue and without, with even more glue,...

Even more since the same Live-Z (even without the 50nm correction on the left) and the same 3D model, just sliced in Slic3r to the gcode for ABS works completely fine, that's what's wondering me the most.

First image

second image

Re: Getting started with PETG (on the Mk2.5)

I'm using Inland PETG. I had to increase the temperature to 250C and slow it way down to get it to stick to glue stick. It still doesn't stick directly to the PEI bed.

Re: Getting started with PETG (on the Mk2.5)

That's why I already switched from PrimaSelect PETG to Prusa PETG, because I thought for that one the slic3r (Prusa slic3r) PrusaPETG settings should be right. For me it seems - independent of what I am doing, PETG has the most preference to just stcik to the nozzle.

Re: Getting started with PETG (on the Mk2.5)

The trick to PETG is to put a Z offset of 0.15 - 0.2mm in the slicer and print the first layer very slowly at the bottom of the temperature range. You can up the temperature on the rest when it speeds up. You also may need to increase the extrusion multiplier slightly and the K value as the filament is just falling to the bed/print so the amount extruded must be just right.

Regards,

Martin

Martin Wolfe

Re: Getting started with PETG (on the Mk2.5)

Dear Martin,

thanks for the ideas, what to try, too. Can you help me a little bit and guide me to where to set the Z offset in slic3r? I have found the extrusion multiplier, but I can only set that globally and not modify it for the first layer (for temperature I can do that, of course). And – what's K value? I never heard of it and google is not much help.

Re: Getting started with PETG (on the Mk2.5)

I did a short morning test with these squares https://www.thingiverse.com/thing:1776031 and the result actually does not look that bad. It's completely the same settings I ended my test with the above file, just in the version with a lot of glue on the bed (but that did not work on the above file either).

The middle square is not perfect, but in total this looks quite reasonable. I am totally puzzled, why the above file won't print, if this one looks that good. Somewhere I have a huge misunderstanding in my head concerning PETG.

Re: Getting started with PETG (on the Mk2.5)

The Z offset is found in 'Printer Settings/General/Size and Coordinates' the highlighted number in the screen shot below

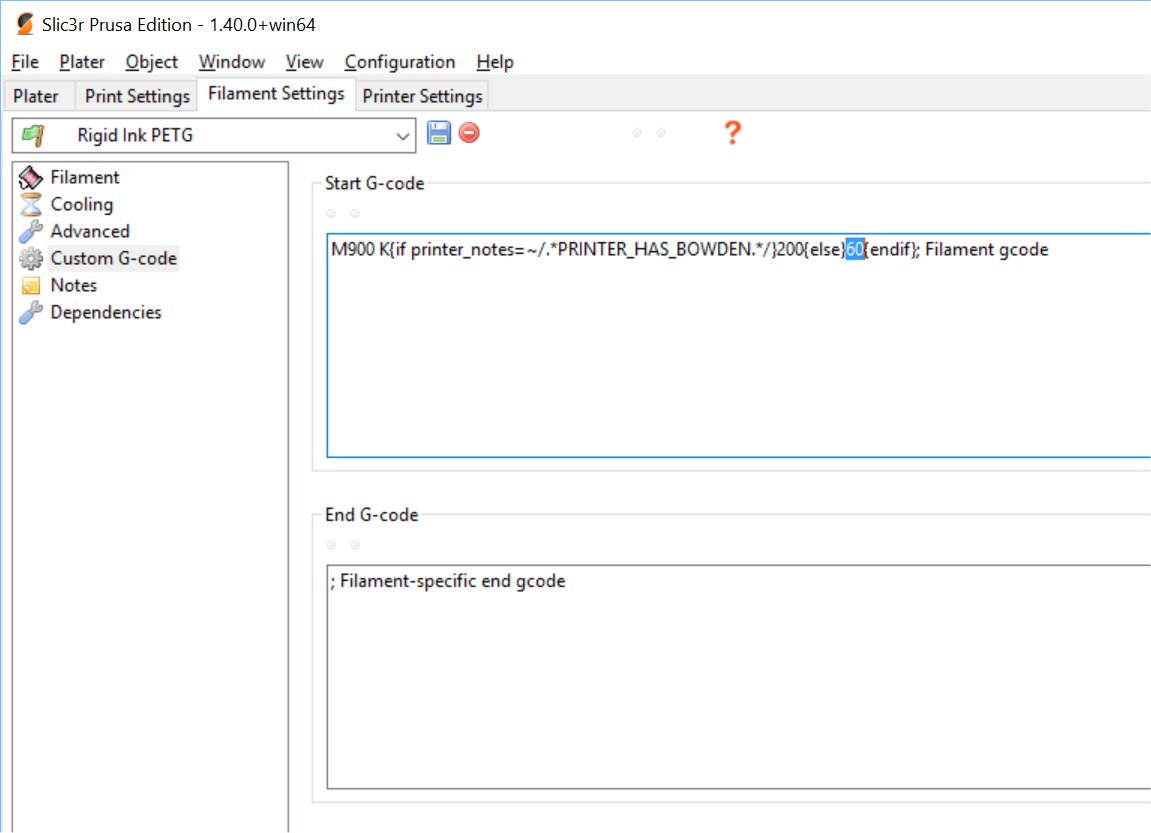

The K value is found at 'Filament Settings/Custom G-code/Start G-code' the highlighted number in the screen shot below

K value is the ratio off extrusion on slow parts (corners) to fast parts (long straight runs).

You are correct that the extrusion multiplier is global. It would be nice if it could be set separately for the first layer. As a result my first layer is slightly under extruded but the rest is fine.

Regards,

Martin

Martin Wolfe

Re: Getting started with PETG (on the Mk2.5)

Thanks for the heklp. May I asked, what the K value actually does?

I now first tried adapting your values (K60) (Z offset 0.2) and an additional extrusion of 1.05

(each enabled and disabled and one short print try with my first layer from above) none of that

yielded anything nearly as good as the one above; so for most cases the PETG had the favour

of just building a large blob at the nozzle.

Compared to my ABS approaches, it seems that the Z-Leveling (Z offset & Z Live) has to be :_veeeerry_ precise

and in total that's so many values which I don't know the effect of... is there maybe some visual guide somewhere saying: Your Print looks like this or does that THEN do this change to your settings?

I feel like turning something like 8 knobs randomly without getting any feeling for the effects.

Re: Getting started with PETG (on the Mk2.5)

Actually because of that Z offset PETG is a lot more forgiving on bed levelling. To quote Rigid Ink "It is like printing on air"

Regards,

Martin

Martin Wolfe

Re: Getting started with PETG (on the Mk2.5)

Since my last post I have changed my nozzle and heater block of plated copper ones. After some initial problems I managed to tune PETG in for this nozzle and block combination without sock.

I increased my Z offset from 0.2mmm to 0.3mm this completely eliminated any dragging. So I upped my first layer speed to 30mm/s (the default in Slic3r as set by Prusa.) A perfect first layer at speed.

Regards,

Martin

Martin Wolfe

Re: Getting started with PETG (on the Mk2.5)

I am still trying and getting nearly constantly the result as above independent of Temperature, LiveZ/Z offset (they are the same of course) and (a little bit with) extrusion – my first layer speed is still the standard from Prusa/slic3r. I think I am missing something important in my parameters, but can't find which one. K is 60 as in your settings...

Though the tests since my last post where not that many, I am a little busy in my job these days.

Re: Getting started with PETG (on the Mk2.5)

Don't bother looking for the K value. Just set the first layer height to 0.3mm instead of the usual 0.2mm. That gives far better results than changing the K value anyway.

Regards,

Martin

Martin Wolfe

Re: Getting started with PETG (on the Mk2.5)

So I played with Z offset and Z-Live for 2 hours now. I can't get anything consistent together here (240° nozzle, 85° bed, no glue but isoprop before every print)

I did a test for all values from a Live Z 430 to 477 at 50% Prusa speed (not set in slic3r but at the Mk2.5); up to 450 it is printing on air, keeping everything at the nozzle (for the detail letters above, the first round of getting filament running always looks fine to me, not too squishy, nicely laid...). 452 worked nearly, 455 worked for a nearly perfect first row of letters and the second was not on the bed at the top and then everything went down. 457 swuished one line in the other and then everything went bad) from 460 on the nozzle dragged a little filament nto one neighboring line and everything went bogus.

I can't get any reasoning in a layerheight with PETG, to me that seems _completely_ random. I am now just out of ideas.

Re: Getting started with PETG (on the Mk2.5)

So while the last Z-Live-values where with Z offset 0 I am not at Z offset 0.3 and Z-Live 730, K 60, 250° Filament, 85° bed, 100% speed on Prusa Print (rest of speed ist standard of PrusaPETG); I am slowly running out of PETG (1kg without any succesful print) and here is my last phenomenon that I can't get a clue on.

I printed TWICE with completely the same setting, did the same preparations before: clean bed with isoprop. Clean nozzle with brass brush (no visible filament remaining), both performed directly afterwars (actually after the better one I tried to reproduce)

Actually I stopped the second one when it started to “fill” the first (front) square since there was already a full blob building at the nozzle.

Even for the first print you notice a small error at the front, where the filament decided to stick to the nozzle (lost it when starting to fill the center) – and it does that _COMPLETELY_ at random, sometimes it also stops that randomly sometimes it does not.

So my last question before finally giving up: HOW can I avoid, that PETG sticks to the nozzle that much and that randomly? I really can't find settings (K,Z-Live,Z offset, speed, K, ° filament, ° bed) where that does not happen – after nearly 1 kilogram of PETG only doing first layers :/

Re: Getting started with PETG (on the Mk2.5)

I can't get anything consistent together here (240° nozzle, 85° bed, no glue but isoprop before every print)

That 240°C nozzle and 85°C bed could be part of your problem. The first layer nozzle needs to be as cold as possible with the bed as hot as possible. Slow down your first layer print speed if you have too to get that temperature down. PETG is very attracted to hot metal. My temperature settings for te first layer are currently 220°C nozzle and 90°C bed. I would go hotter with the bed but I have already ruined one print fan nozzle doing so. Once I am in a position to print myself a PC print fan nozzle I will experiment again with higher bed temperatures. When I was still on the stock heater block and nozzle I had to run with a first layer temperature of 230°C. The lower print temperatures and high bed temperatures is the magic that makes PETG still to the bed a little too well necessitating the use of a separator to prepare the bed.

Regards,

Martin

Martin Wolfe

Re: Getting started with PETG (on the Mk2.5)

Hi Martin.,

thanks for the patients and trying to explain so many things – is there some page where this is explained? Somehow for ABS that was easier, I think.

However, concerning yxour temperature advice – I slowly increased the temperature top get rid of blobs on the bed that looked like the filament not consistently flowing. When ging back to 230 or 220 now – the image of the bed gets even more boring (the remaining settings kept as above, just trying Live-Z +-50 manually) – then from the start _all_ filament sticks to the nozzle. I'm sorry, maybe, I should really give up, when this spool is empty.

Re: Getting started with PETG (on the Mk2.5)

Just to check that you are moving your Z in the correct direction. Lest say your Z for PLA is -750 then you would need -550 or even -450 (my current PETG Z offset if 0.3mm) for PETG.

Regards,

Martin

Martin Wolfe

Re: Getting started with PETG (on the Mk2.5)

My PLA (or better ABS) Live Z is -650. Z-Offset 0.3; the above ones are with about -450, the frames look a little better But it indeed doesn't matter for -850 the frames/boundaries look a little better but the fil in still does not. But after again 3 hours this morning I am just getting tired of looking at failed prints (for over 4 weeks); still thanks for responding so fast. I think I'll just give up for now. I just don't get any feeling for the values (for ABS I have the feeling for seeing the first layer and knowing what to change/adapt; after all these experiments for PETG – it all feels just randomly failing, or to be precise randomly working but mostly failing).

Re: Getting started with PETG (on the Mk2.5)

Sorry I could not be of more help. One thing I have taken to doing when printing PETG is cleaning the exterior of the nozzle once it is partially heated at 160°C before letting the print start. However the few times I have forgotten this it has not had any impact beyond the splatter that is on the nozzle from the last print falling to the bed during levelling.

Regards,

Martin

Martin Wolfe

Re: Getting started with PETG (on the Mk2.5)

No, thanks for trying so many ideas 🙂

I think the splatter is my main problem. Even with cleaning the nozzle very carefully (which I did for the last week), such that there is no filament visibly left at the nozzle, the first parts stack up again during the first round of skirt and I think thats causing most of the randomness, that theres always stuff at the nozzle that's leaving it somewhere in between.

Because the layed lines (for -850) look as I would expect them for ABS – just slighty squished layed onto the PEI; and the one print that nearly worked today had nice closed surfaces. Repeating the same print with the same settings messed everything up again due to splatter. For me that all seems so much random, that I can't get any feeling for using PETG for all the time I am fighting it now. And now I'm tired of fighting.