RE: Any info on the Prusa XL?

@reddawg

That is the only reason? You are willing to give up real-estate and fight with bed leveling to nozzles for that? There has to be a better option.

This will work until something better comes along:

And some good stuff here:

I need it. For the size stuff I (typically) print, 400 x 400 x 400(?) will be more than adequate. YMMV.

Hear ye, Hear ye! Step right up folks and get your Government salvation here! Less than $.002 per word! Amazon.com/dp/B0B8XMMFP4

RE: Any info on the Prusa XL?

@christopher72

Is it this one? https://www.monoprice.com/search/index?keyword=dual+extruder Discontinued @$900?

Hear ye, Hear ye! Step right up folks and get your Government salvation here! Less than $.002 per word! Amazon.com/dp/B0B8XMMFP4

RE: Any info on the Prusa XL?

Is the MMU2S not working well enough to use for dissolvable filament? Or is there something else getting in the way of using the MMU2S for that purpose? Build volume dimensions aside, I'm just trying to understand why some here hold the view that an automated toolchanger is the better way to print using a combo of both regular filament and dissolvable filament. I'm not disagreeing, I'm just trying to understand the pros/cons of the two different approaches.

RE: Any info on the Prusa XL?

@reddawg

That is the point 400x400x400mm will become 350-375x350-375x350-375mm if you a dual extruder head. That is ignoring the fact that it takes extra diligence to tune in two heads. It is a big assumption that Prusa can get this right. Based on the struggles of the MM2s, I suspect that will be a challenge.

--------------------

Chuck H

3D Printer Review Blog

RE: Any info on the Prusa XL?

@reddawg

That is the point 400x400x400mm will become 350-375x350-375x350-375mm if you a dual extruder head. That is ignoring the fact that it takes extra diligence to tune in two heads. It is a big assumption that Prusa can get this right. Based on the struggles of the MM2s, I suspect that will be a challenge.

Actually it's more like 350-375x400x400. The dual extruder will only impact the X axis (at least based on the typical orientation of dual extruders).

RE: Any info on the Prusa XL?

Well, Chuck.... Since you're always looking for comparisons to do, I'd love to see a round-up and quick test of multi-filament solutions:

- MMU2 (multi-filament feeder)

- Palette (filament chopper)

- Combined dual/multi-extruder (e.g. E3D Kraken or Chimera)

- Dual independent extruders (independent X axis)

- 2 filament/1 nozzle extruder (e.g. E3D Cyclops)

Evaluation can include the usual quality considerations, but also:

- Impact on build area.

- Complexity of installation.

- Complexity of operation.

- Complexity of maintenance.

I don't have an immediate need for a solution, but based on what I know now, I'd be tempted to try a Cyclops 2 filament/1 nozzle solution. Simpler than the MMU and likely to fit nicely into existing enclosures.

Of course, this would be an ambitious and pricey project! Maybe a collaborative effort or over an extended period of time?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Any info on the Prusa XL?

Is the MMU2S not working well enough to use for dissolvable filament? Or is there something else getting in the way of using the MMU2S for that purpose? Build volume dimensions aside, I'm just trying to understand why some here hold the view that an automated toolchanger is the better way to print using a combo of both regular filament and dissolvable filament. I'm not disagreeing, I'm just trying to understand the pros/cons of the two different approaches.

The MMU2 is not great for true multi-material printing in general. There are two primary issues as well as two additional related issues.

The first issue is when using filaments with different temperature requirements. PrusaSlicer doesn't handle this properly and it will start printing before the nozzle is at the desired temp. This can lead to carbonization (e.g. printing PLA while the nozzle is still way too hot) or straight failures to extrude (trying to print a high temp filament after a colder one). Depending on your purge volume (see next items for more on that) and the temp swing it is possible for the nozzle to still be at the wrong temperature by the time it gets back to the actual print which may have a negative impact on print quality. This can be gotten around with gcode tweaks, but is still not ideal (see next item).

The next issue is purging the prior filament properly and there are two issues here. The first (going back to the previous point) is that during the purge the heat needs to find a balance between both filaments so that the old filament can be purged without causing problems (e.g. not too cold that it clogs or too hot that it burns). The second is the amount of purging needed to produce a clean extrusion in time for the print itself. In my (limited) experience with PLA and PVA I was up to a 1000 cubic mm purge and still seeing PLA in the PVA and PVA in the PLA. The observed result of incomplete purging is that the printed part is significantly weakened in the areas following a tool change.

Related to the purging is the amount of wasted plastic used in a wipe tower. Having dedicated hotends for each filament means such a tower is not needed and thus a significant savings in filament. Depending on the required tool changes it is not uncommon for the wipe tower to consume more filament than the printed object itself. A 2 color Benchy, for example produces a 40g wipe tower while a 5 color Benchy's tower is over 100g.

The other related issue is one of time. While there would certainly be "lost" time for switching physical tools, that should be in line with the time it takes to retract the filament in the MMU2 and load the next one. The MMU then requires more time to adjust the temp (if needed and if the gcode is modified to do so) as well as the time it takes to do the wipe process (before unloading and after loading). The length of time for the wipe process is directly related to how much volume is being purged. My experience with multi-material prints says that 600 cubic mm is the minimum viable purge volume and that comes out to about a 2.5 minute tool change (without waiting on temp changes) with only about 30s of that being the unload and load process.

The MMU2 is a useful tool and a decent compromise, but it does have limitations.

RE: Any info on the Prusa XL?

[...] The first issue is when using filaments with different temperature requirements. [...] The next issue is purging the prior filament properly and there are two issues here.

Based on my understanding, I'd expect this to be a problem for any of the x-in/1-out designs, whether MMU2, Palette, or Cyclops. Purging is wasteful of material, build area (probably as much or more than a 2nd extruder would be), and time. Mixing temps and associated oozing issues make true mixed-materials (e.g. PLA and PETG) difficult or impossible.

Thinking about this, I can see the appeal of true separate extruder-hotend paths (e.g. 2-in/2-out Chimera), but 1st layer calibration with 2 independent nozzles on a combined X gantry will be complicated. As noted by others above, there is a penalty in terms of build area.

Two independent extruder-hotend X & Z paths (e.g. a Zidex design) allows adjusting the 1st layer of each nozzle to be set relatively easily, but now you're adding considerable cost & complexity, and greatly reducing build area ... unless you can move one nozzle completely up above the other perhaps? Definitely will cost Z build space if so.

I really do think and hope that we're in the "dot matrix" days of 3D printing. What we really need is a new technology to move forward in a big way. I'm not going to spend more than hobby $ on anything for the next few years.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Any info on the Prusa XL?

[...] The first issue is when using filaments with different temperature requirements. [...] The next issue is purging the prior filament properly and there are two issues here.

Based on my understanding, I'd expect this to be a problem for any of the x-in/1-out designs, whether MMU2, Palette, or Cyclops. Purging is wasteful of material, build area (probably as much or more than a 2nd extruder would be), and time. Mixing temps and associated oozing issues make true mixed-materials (e.g. PLA and PETG) difficult or impossible.

You are correct that these issues apply to any X-in/1-out solution.

Regarding the wasted build space, there are games you can play in that regard.

The first is that you can control both the placement and orientation of the wipe tower. So (using MK3 dimensions) if you wanted to print something that was say 250x100 (and assuming both colors are needed on the extreme ends) you could position the wipe tower so that you could use the full X range while a dual nozzle option would only have have 220mm or so in the middle where both nozzles could reach.

Another option is that if you can wipe to infill which will reduce the size of your wipe tower. If there is enough infill in your print it is possible to not end up with a wipe tower at all. If your outer perimeters aren't opaque enough, however, that can have undesirable effects on the visual quality.

While those two options are built into PrusaSlicer, some of us have also played with sneaking a purge bucket at the end of the X axes with some degree of success. This takes fiddling to make work and you have to take control of the purge process in the gcode, but the end result is no loss of bed space (we also saw some time reduction as we could perform the purge at a faster rate).

Thinking about this, I can see the appeal of true separate extruder-hotend paths (e.g. 2-in/2-out Chimera), but 1st layer calibration with 2 independent nozzles on a combined X gantry will be complicated. As noted by others above, there is a penalty in terms of build area.

Or marketing can cheat like Ultimaker does on the S5 and claim that both nozzles have access to the entire build area. Of course the reality is that they simply made the build area smaller than the actual X travel distance so that you just don't see the lost space on the platform.

Two independent extruder-hotend X & Z paths (e.g. a Zidex design) allows adjusting the 1st layer of each nozzle to be set relatively easily, but now you're adding considerable cost & complexity, and greatly reducing build area ... unless you can move one nozzle completely up above the other perhaps? Definitely will cost Z build space if so.

I really do think and hope that we're in the "dot matrix" days of 3D printing. What we really need is a new technology to move forward in a big way. I'm not going to spend more than hobby $ on anything for the next few years.

I don't know the full details of how it works, but the PolyJet seems to work similar to being a cross between SLS and FDM printing. My understanding is that a base material is laid down similar to SLS (so supports are not needed) and additives (color only?) are added just prior to fusing which changes the properties of the base material.

I was part of Hero Forge's kickstarter for full color prints and while I don't think the coloring is WYSIWYG with their online tool, the result is still damn impressive (SLA detail quality with an incredible color range).

Definitely out of the hobbyist level printer though 😆

RE: Any info on the Prusa XL?

@bobstro

I never really thought about the cyclops. Good idea.

It will work if you are planning to use two types of the same filament such as 2 colors of PLA.

https://e3d-online.com/products/cyclops

--------------------

Chuck H

3D Printer Review Blog

RE: Any info on the Prusa XL?

If you look at the Stratasys 250-mc this is sort of what they are trying to accomplish (SORT OF).

We used these at Boeing in our tooling area. the machines are OK at best as far as print quality (Prusa was better at finish and quality).

The biggest thing I seen was cost to maintain at $300+ per filament cartridge (and not refillable) and other cost.

They are built like tanks and had some really cool design featchers like purge box for the filament changes and automatic filament change on the head.

http://precenglab.riteh.uniri.hr/stratasys-fortus-250mc-3d-printer/

And this is a used desktop $17,500.00, you get the pitcher here as why we pay so much for government spending and cost of doing business.

RE: Any info on the Prusa XL?

Another attractive feature of the toolchanger design would be that it might afford a degree of redundancy that might allow your printer to keep running while you're asleep or otherwise away: in theory if a particular printhead runs out of filament or gets jammed/clogged, the toolchanger could demount it and replace it with another and keep on printing. Time is money, and so that alone might help justify either some or all of the cost, especially for someone who is deadline driven or otherwise in a hurry.

RE: Any info on the Prusa XL?

It does indeed look as though doing a toolchange need not take very long at all:

Looks quite promising! Limited need to purge, and I presume any oozes would be wiped off on a wipe tower or something. It doesn't really intrude upon the build plate either (unless you want to make an argument that the space they occupy could have been allocated to more build area instead, but, meh, I have space on my Ender 5 Plus that's outside the build plate that isn't currently being used for anything, so I don't completely buy that argument).

RE: Any info on the Prusa XL?

Has anyone seen of heard of FDM printing with resin ? It would be fairly easy I guess to have several needles in a cone-like structure depositing different colour/property resins. All one would need is an added UV lamp at the nozzle, a bit like UV printers.

Having problems with bed adhesion every morning...

RE: Any info on the Prusa XL?

@reddawg

That is the point 400x400x400mm will become 350-375x350-375x350-375mm if you a dual extruder head. That is ignoring the fact that it takes extra diligence to tune in two heads. It is a big assumption that Prusa can get this right. Based on the struggles of the MM2s, I suspect that will be a challenge.

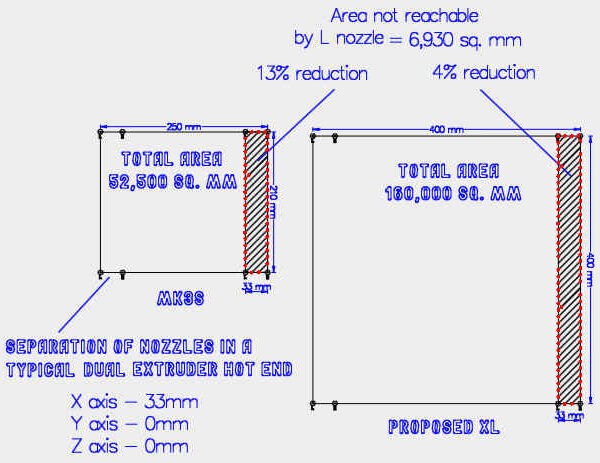

Chuck, you have a basic misunderstanding about how typical dual-extruders work. The following diagram shows the metrics for the MK3/S and (probable) XL using the geometry of my ancient MakerBot "Brooklyn Replicator" extruder pair. Without wasting a lot of time looking them up, I imagine designs that are not a decade old may be more compact, but here's a diagram that may help:

Hear ye, Hear ye! Step right up folks and get your Government salvation here! Less than $.002 per word! Amazon.com/dp/B0B8XMMFP4

RE: Any info on the Prusa XL?

After looking closer at the toolchange video, the whole issue seems to be a false dichotomy: the toolheads are being stored above the build plane, so there's no need for trading off. As per @bobstro's star trek quote, it's only if you think in 2D that they appear to interfere. The filament and extruders, if that's what they are, mounted below could be mounted just as easily on the other side of the cube wall.

RE: Any info on the Prusa XL?

@reddawg

Given your diagram wouldn't the Right hand nozzle be unable to reach a similar 33mm wide strip on the LEFT side of the print area ? As such only the middle common area would be available to both nozzles. So that would be an 8% reduction instead of 4% on your 400x400 plater. Sorry unless my basic math has atrophied badly.

RE: Any info on the Prusa XL?

@reddawg

I understand, but your math is wrong. You will lose the same distance on both sides if you are using dual-extrusion. With a tool changer, you will lose zero.

--------------------

Chuck H

3D Printer Review Blog

RE: Any info on the Prusa XL?

@cwbullet

Hear ye, Hear ye! Step right up folks and get your Government salvation here! Less than $.002 per word! Amazon.com/dp/B0B8XMMFP4

RE: Any info on the Prusa XL?

@reddawg

I think it is important to understand the tool changer. If you want a dual extruder, you can add it yourself. If you want or need 20 heads, you can add it yourself. That is the beauty of a tool changer.

--------------------

Chuck H

3D Printer Review Blog