Results input shaper

How satisfied are you with the results of Input Shaper?Relatively little feedback comes here.

I am satisfied with some things, but with some I have the impression that there is no effect at all.For example here.

Belt tension was checked.

I am excited to see what improvements will come ..... or not.

RE: Results input shaper

I calculated the frequency by measuring and came up with X at 47.8.

The value in the firmware is 50.x. Should have a sufficient effect.

RE: Results input shaper

The positive side: you can cut down the printing time without loosing too much quality. On the attached picture you see standard MK4(23min); MK4 with speed settings (18 min) and MK4IS (13 min).

There is room to improve - but this is Alpha SW.

RE: Results input shaper

I’d be happy with that quality for such a time saving!

RE: Results input shaper

The cubes look good. But the ghosing on my print is extreme. I repeated the print without IS at 0.20 speed. The ghosing is gone but the vertical artifacts are still there. But they are not influenced by IS either. I'll post a picture tomorrow. I would appreciate if you post more pictures of your prints. whether good or not so good. This gives the developers feedback on what works and what doesn't.

RE: Results input shaper

One more item or problem I posted here:

Vibration artefacts on Y-Axis – Assembly and first prints troubleshooting – Prusa3D Forum

It is not related to InputShapeing - but due to the higher speed it showed up during my testing. Prusa support could not help me and I have no clue how to fix it. It might be some mechanical coupling/resonance - but could also be the Y-Stepper motor - but how to prove?

Because quality comes first to me and I do not care about longer print time I stepped back to standard and wait for the final InputShaper SW.

RE: Results input shaper

I printed the part again with 0.20 speed on the MK4 and Mini. When printing with the mini, Filament was no longer enough.Not bad, was not a good quality.

The ringing is gone, the vertical artifacts are there for everyone. That still looks best with the mini.

RE: Results input shaper

Try to increase the y-belt tension (even higher than proposed by the tuning App)- did help on my problem.

RE: Results input shaper

I'm now in the middle with the belt tension. Measured with the app and the prusa tool. I'll go to the upper limit.

RE: Results input shaper

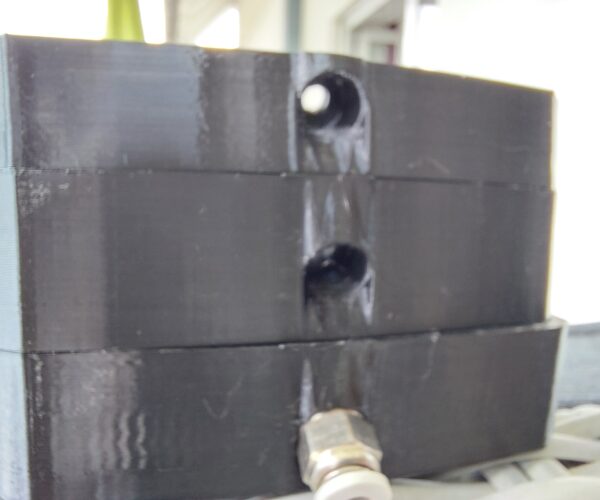

from buttom to top: medium, high and very high tension (whatever that means). I printed this in "vase mode" with very high speed (300mm/s).

RE: Results input shaper

I have now set the Belts to a bit to Tight. I don't want to do more. Not because of the Belt, rather because of the motor bearings.

I am very satisfied with such things with the input Shaper version. The speed impresses me with the quality.

RE: Results input shaper

what frequency did you set yours to on x and y?

RE:

I used the "ringing tower" and instruction on:

Input Shaping | Marlin Firmware (marlinfw.org)

On my printer:

X: 42 Hz

Y: 41.2 Hz

For those who don't know:

the InputShaper frequencies can be found on the "Printer" Setting on "custom gcode". At the end of Start-gcode you can find the M593 commands:

M593 X T2 F42

M593 Y T2 F41.2

Dont forgett to change the gcode setting on "layer change":

M593 Y T2 F{interpolate_table(extruded_weight_total, (0,41.2), (300,30.5), (800,20), (10000,20)) }

this is the weight compensation on the Y-Axis

RE: Results input shaper

I left the original values. For the first part, I calculated X to be 47.8 Hz.

Before that I did a test print with the part from Klipper. I don't remember the exact values, but they were pretty close to the originals.

I want to try the Marlin variant. Let's see what comes out.

I've posted it elsewhere, but with no response. It would be interesting if many users post their frequency here to see if there are big differences.

@Volker did you also change the input shaper? MZV is currently in the settings. Klipper recommends EI more for bed slingers.

From the Klipper Doku.

- For most of the printers, either MZV or EI shapers can be recommended. This section describes a testing process to choose between them, and figure out a few other related parameters.

- EI shaper may be more suited for bed slinger printers (if the resonance frequency and resulting smoothing allows): as more filament is deposited on the moving bed, the mass of the bed increases and the resonance frequency will decrease. Since EI shaper is more robust to resonance frequency changes, it may work better when printing large parts.

RE: Results input shaper

My frequency

X 44.6

Y 37.8.

Input shaper as intended by Prusa T2/MZV is better than T3/EI for me.

RE:

M593 X T2 F41.21M593 Y T2 F47.65

;BEFORE_LAYER_CHANGEG92 E0.0;[layer_z]M593 Y T2 F{interpolate_table(extruded_weight_total, (0,47.65), (300,32.5), (800,20), (10000,20)) }M201 X{interpolate_table(extruded_weight_total, (0,4000), (1400,2500), (10000,2500))} Y{interpolate_table(extruded_weight_total, (0,4000), (1400,2500), (10000,2500))}M74 W[extruded_weight_total]

bumping faster for the last one.

bumping to (same print type different dino)

GEEETECH HighSpeed PLA FL:200 OL:190 Bed:60

filament overrides

Length .2

Lift.2

Retraction Speed 45

Min. Trav. 1.5 RoLc active.

(edit)

Still playing with retraction - but maybe I should try Linear/pressure Advance first.

RE:

Currently Printing

bridgemonger - Twitch

Edit* funny thing is, I forgot to change infil/supports. I bump down and change from the "stock" profile. -I bumped way down too 100 for the normal pla I had, and am now increasing steadily to find happy spot.

RE: Results input shaper

Just printed all parts for the MMU3. In comparison to the provided MK3 gcode the printing time was less than half of the time and the quality with PETG (without any modification) just perfect. Only very minor ringing on shiny sufaces - but you need to look very very close to see them. Very satisfied

RE: Results input shaper

Do you also have the original frequencies? Or did you print with your determined ones?

There is supposed to be an RC firmware later this week. The new slicer profiles are already here. Tomorrow I want to reprint a part that I printed with the Mini. That had quite a bit of ghosting.

Print page in the new quality profile 3:30 instead of over 5 hours. In Speed it would even print in 2:40. And I expect it to look better....

Small notes in a guide to printing for a mechanically stressed part would be advised to print in silent mode when using a Bambulab because the stability of the part is otherwise too bad. Speed isn't everything.

RE: Results input shaper

On my printer:

X: 42 Hz

Y: 41.2 Hz

Hard to see and even more difficult to take pictures