Seeking advice on print flaws

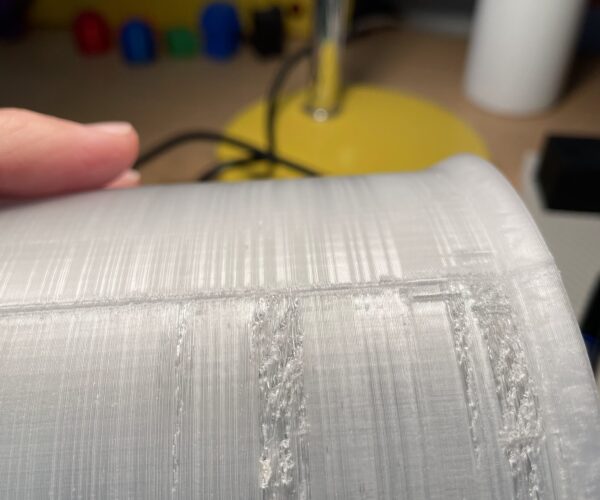

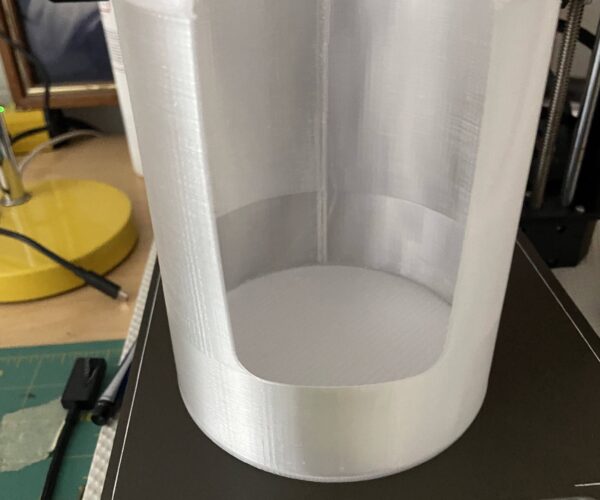

I'm printing with MakerShaper PETG at 230 and as you can see from the pictures the print starts out pretty well for the first few inches. I set the seam to the back so that I wouldn't get pips all over the place, which for this print looks better. I dried the filament for about 5 hours before printing although I also store it in a dry box when not printing as well. I am not using vase mode for this because I want it to be stronger/thicker than I get with vase mode. But as you can see in the full shot as well as the other two there are some flaws that occur part way up the print. Can anyone advise me what might be the cause and or things to try to tune this away? If I could get the whole print to have similar quality to the bottom section I'd be thrilled.

Thanks

For the curious, this a chawan holder to stack rice bowls so they don't tip over when stored.

Take a look at:

Cheerio,

RE:

After reading that post and responses it does look similar, although in my case the walls are straight up, so one might expect each slice to be for the same size wall. I had previously noticed the "gap fill" and tried playing with extrusion widths and # of perimeters to see if I could get rid of the gap fill.

I don't see the issues in the sliced visualization, other than the existence of the gap fill. Would playing with the wall thickness in Fusion 360 possibly change the need for gap fill and then get rid of these issues?

Thanks

It's certainly worth trying.

Cheerio,

RE: Seeking advice on print flaws

To follow up...I messed around with various wall thicknesses in Fusion360 and eventually reduced the "Gap Fill" to almost nothing. Now the print looks much better. Maybe this will be helpful to someone else in future.