Printing a Box - Why only one edge is bad?

Hi there

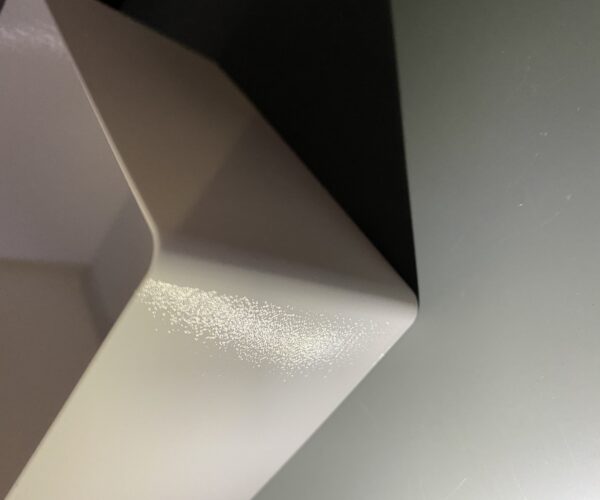

I recently have printed a 90x100x60 box with only 1mm shell thickness with original Prusament PETG and standard 0.4 nozzle. Normally i leave the settings as default whenever possible. The box looks pretty good, except one edge/corner looks quiet awful. I think this is the edge where the printer changes to the next layer. I only tweaked the flow factor to 100 because during the first layer i saw some small gaps between the lines.

On the pictures, you can see how the bad edge and the good edges are look like.

Does anyone know how this can be fixed?

Many thanks!

Best Answer by herbert:

This is the seam position, where the layer change happens

RE: Printing a Box - Why only one edge is bad?

This is the seam position, where the layer change happens

RE: Printing a Box - Why only one edge is bad?

Thanks, for the hint, i will try out!

RE: Printing a Box - Why only one edge is bad?

I have the same problem with the seams, when I print the same thing on my other printer, a cheap flashforge finder, the result is much better. My first thought when I unpacked my mini was that the construction felt lean and allows a lot of movement when it only has one arm up.