PETG Headaches

Hey all,

First time posting here, so forgive me if I'm leaving out something important.

I've been wrestling with getting PETG to print on my mini for what feels like 2 weeks now. I have absolutely no issues with PLA filament from any brand -- it comes out immaculate. But regardless of the PETG, I get all sorts of awful monstrosities.

I've tried a number of different things in all different permutations. +/- anywhere from 5-20 degrees on both the nozzle and bed, turning the fan off for the first several layers, slowing the print speeds way down, adjusting the layer heights, changing retraction length and speed, Z offsets, tossing the filament in the oven to bake out moisture... it seems like nothing is giving me really stellar improvements.

Initially, I couldn't get PETG to adhere to the bed for the life of me, but I'm at least at a point where things will print, they just print in such a way that I'm not sure it's worth using the part.

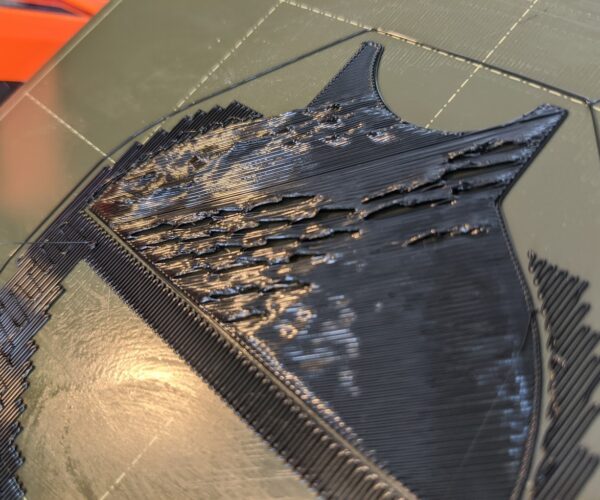

I've thrown in some pictures of my most recent attempt (a water bottle holder for my bike). Right from the start, I've noticed that there's weird lifting in the first layer. I suspected that maybe my nozzle was too close and the filament was attracted to the hot metal and drawn upward, but if I raise the nozzle far enough for that to not be a factor, I wind up just dragging pieces of PETG around through time and space instead of actually having it stick to the plate. I've cleaned this sucker more times than I care to mention, I've rotated to see if it was just some flaw in the surface (it's not, it does the same thing in the same spot), and I've witnessed this happen on entirely different prints which I assume rules out flaws in the underlying model.

I haven't really even gotten to the point of tackling all the random imperfections in the middle of the print, some of which I think are still moisture related, and others I haven't really researched yet.

I'm about ready to just give up on PETG all together, so I'm hoping you all might have some more guidance for me.

RE: PETG Headaches

Have you performed a first layer calibration after changing the filament? Different temperatures of the heatbed affects the MINDA probe and it needs adjustment.

Other than that there is a lot of underextrusion. Maybe you need to also adjust the tension on your idler screw?

Have you printed a heat tower for this filament?

I have some trouble printing PETG too mostly because of incosistent layer height but overall I have managed to get some decent results.

Original Prusa Mini + Smooth PEI

Prusa Slicer 2.6.0

RE: PETG Headaches

I've done the first layer calibration, but it seems like, while things might go great during the calibration, it's a totally different world once I start printing larger pieces in PETG.

I got a temp tower out -- looks like the 230-235 range looks best with the particular filament I'm working with at the moment.

I'll take a look at the idler screw tension to see if that helps any.

I have managed to get some okay prints the past few days after tweaking some of the settings, but I do still see some abnormalities. The first few layers look a little more fibrous than subsequent so that's probably just some more tweaking of the first layer settings, I'm guessing. I've also noticed that any time there is a jump between points and the print head travels abruptly, it leaves a little blip in the wall where it drags a tiny bit of filament away. Not sure what would help most with that -- maybe enabling the Z lift during retractions? Threw in a picture below of what I'm talking about.

RE: PETG Headaches

@geoper2

I just finished a first layer calibration on my mini with PETG. I had to crank it down from the -1.213 I was using for PLA to -1.240 for the PETG on the textured plate. I think I could even go lower. I would have thought the textured plate would have made me raise, not lower, my Z-offset.

I haven't tried to print anything with the PETG yet, but probably will today...

I'm not a mad scientist, I'm an angry engineer in training.

RE: PETG Headaches

@brianbag

Those are seams and you will never manage to hide them fully because its where the layer changes. You could change their position in Layers and Perimeters in the advanced filament settings. Other than that I can see that your results are better.

Original Prusa Mini + Smooth PEI

Prusa Slicer 2.6.0

RE: PETG Headaches

The first layer seems a little tall/high try a little more z offset and did you have the part cooling fan on or on high? I have horrible issues with another printer when the part cooling fan starts with PETG, PETG likes to cool slowly I guess or it will warp/curl/not stick to the previous layer all that well.

RE: PETG Headaches

@paddoswam

I had read that for PETG you should raise the nozzle up higher, otherwise it'll draw up to the nozzle as it's printing and goop up. It seems like I took that too literally and I was way too high. I wound up watching someone's YouTube video of a simple print from front to back of one layer of a rectangle and what the lines should look like. In the end, my best results were not all that different in height from other filaments, and I needed to compress the bead a bit as it printed.

Here's a more recent print after readjusting my offset.

RE: PETG Headaches

The first layer seems a little tall/high try a little more z offset and did you have the part cooling fan on or on high? I have horrible issues with another printer when the part cooling fan starts with PETG, PETG likes to cool slowly I guess or it will warp/curl/not stick to the previous layer all that well.

My guess is the same. I would say you are too low.

--------------------

Chuck H

3D Printer Review Blog

RE: PETG Headaches

I am fairly new with PETG as well and went and bought the textured plate but for the life of me I couldn't get it to stick. I switched to the messed up side of my smooth plate because I've seen a few pics of the surface tearing from it sticking too well. So far I haven't had any issues. I adjusted my Z-offset and slowed the printer way down. I'm running the stock parameters in Prusaslicer except I've slowed the infill and solid infills down to 70mm/s and then on the machine I drop the speed to between 45-50 and it's been printing really nice, just really slow compared to what I've been used to with PLA. I'll take the trade off though. Once I'm done with these parts for my E3P I'll go back to tweaking and try the textured plate again with the slower speeds as well. Once I get it to stick better on the textured plate then I'll try and tweak the speeds and see if I can speed it up at all.

RE: PETG Headaches

@shawn-blakeman

I found texture sheet can have some very nice adhesion if you clean it properly 😆 the force of PETG cooling down over this area was so big it lifted sheet from magnetic bed.

https://www.reddit.com/r/prusa3d/comments/iuix2n/speaking_of_textured_sheet_adhesion_problems/

But the real test will be housing for those drawers, it will be 13-hour print, 145 mm height printed standing.