Low nozzle pressure after color change giving me a headache.

First things first: I told PrusaSlicer my Mini has 7 extruders & uses the M600 color change command for the "Tool change G-code" It works just fine doing manual color changes as long as there's not too many in a print. Anyway, onto my problem:

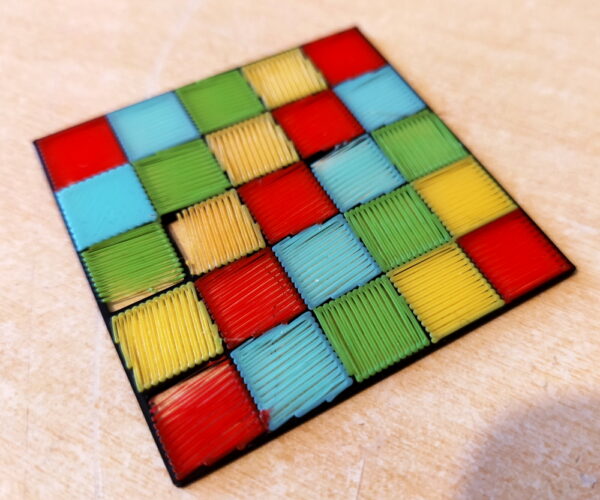

I'm working on a design that includes a 'stained-glass window' effect & the intention was to print several layers for a frame then a single layer including several color changes for the pieces of glass, then another few layers for the other side of the frame. I did a test print & found it missed out the first few extrusions after each color change & you can quite easily see gaps where each color started.

I've since tried changing the "Extra loading distance" setting under "Single extruder MM setup" but that only seems to increase the amount purged after the color change, not the following extrusion.

My next thought was to add some g-code after the 'tool change' to move the print head to the very back of the bed, where I'd leave space for it to print a purge line similar to the one it does at the start of the print. Sadly, the only way I can think to do this is to store the position using G60, do the line, then return to the position using G61 & after some quick tests I found the Mini's firmware doesn't support these g-code commands.

Third work-around I came up with (while I started writing this forum post) was to essentially add my own purge block model alongside the print to avoid any custom g-code shenanigans, but forgot you cannot control the order in which parts are printed. It may end up leaving a half empty 'pane of glass' then a perfectly full block of purge.

Maybe I could increase the flow-rate after every M600, then learn to write a post processing script that returns the flow-rate to normal x amount of moves later.

Anyway, open to ideas.

That is a very loose layer, if it is a first layer then your first layer Z calibration is off ....

... if as I suspect, it is not a first layer then it's pretty good for a single layer bridge. Drop it to the first layer and it should be OK.

Cheerio,

RE: Low nozzle pressure after color change giving me a headache.

They are lots of little single layer bridges. I'd drop it to the first layer.. but that's not what I'm trying to print.

There's going to be the same black frame on top as there was below.

They are lots of little single layer bridges.

Almost impossible to print. They aren't even proper bridges. You are starting each pane in mid air and hoping to adhere to the side.

I'd drop it to the first layer.. but that's not what I'm trying to print.

Tough. You have to design for the medium...

There's going to be the same black frame on top as there was below

Either cut the frame, print one part with the colour panes on the first layer and the other without, glue together post process.

Or: Design the frame with registration points and print the panes as seperate inserts.

Cheerio,

RE: Low nozzle pressure after color change giving me a headache.

I don't think you understand what I'm trying to do here, but thank you for your help anyway.

This isn't an issue with printing a lot of overhangs, we can pretend it's a perfectly normal print with a simple color change in; I'm asking if there's a way to make sure plastic comes out consistently after using the M600 to change filament or if I'd have to resort to firmware changes.

I don't think you understand what I'm trying to do here,

I can see what you're trying to do with this example, perhaps it's not the best choice to illustrate your issue.

I'm asking if there's a way to make sure plastic comes out consistently after using the M600 to change filament

Even if the post-change extrusion is reasonably consistent this example doesn't give it anything to stick to. As a test apply the technique as a surface on a previous layer, if it works then it may be the bridging that needs attention.

Cheerio,

RE: Low nozzle pressure after color change giving me a headache.

Even if the post-change extrusion is reasonably consistent this example doesn't give it anything to stick to. As a test apply the technique as a surface on a previous layer, if it works then it may be the bridging that needs attention.

You're right, this project probably wasn't the best example to use when asking about this problem. But in the past, I've had the same issues changing color, be it on the build plate or on top of other solid layers. It's just not pushing out the first bit of plastic after the swap.

On a somewhat related note, I've noticed the filament has a tiny bit of space to move in the bowden tube when retracting & extruding. Perhaps if I swapped it for a capricorn tube the tighter inner diameter may help with extrusion performance when it comes to the smaller movements.

RE: Low nozzle pressure after color change giving me a headache.

Sorry to dig up this old post, but I'm having a similar issue where, after a color change, the extrusion flow is almost nonexistent for the first layer. This is critical for my model, since I'm adding 5mmx1mm lettering to the top of an object. If the extrusion is too low after the M600, these letters pop right off . See photo for detail (the stringing here is due to wet PLA+, I know-- just showing the M600 problem here; it happens even with dry filament, so I don't believe that to be the problem).