Help with ironing?

Good morning all!

After tuning my Mini, it seems to be printing well. I printed a large plaque and enabled ironing but I'm having some issues with ironing that I'm hoping you may be able to help me work out.

For reference, I've never used ironing but thought it would look great for this large surface.

In some areas of the print, it seems that there is no filament being extracted from the hot-end while ironing. My understanding is there is supposed to be a small amount of filament extracting during the ironing process. I've attached a few pictures that depict this. You'll notice in some areas the ironing looks GREAT. Very impressive. However in some areas you can see large gaps where it doesn't appear to have been ironed. In the left bottom corner you can also see that the nozzle seems to have crashed in to the print.

Please let me know if this is a desirable outcome of ironing. Since I don't know much about it, I'd like to know if this streaking etc is to be expected.

Using Prusa Mini + with Prusament White PETG, default ironing settings: all top surfaces, 15 % flow rate, .1 spacing between ironing passes.

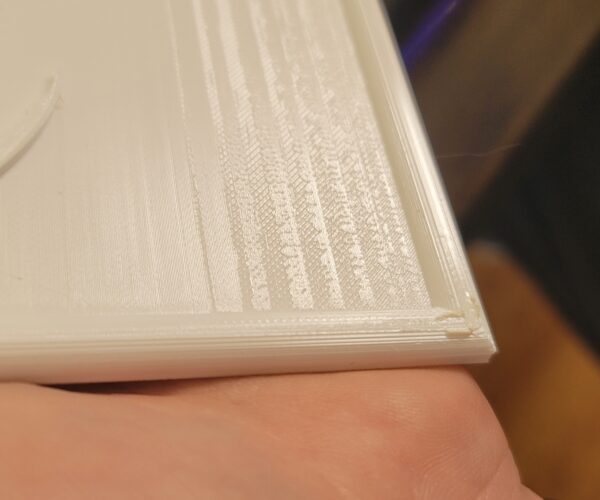

First pic depicts the streaks without ironing and the nozzle crashing in to the corner:

More streaks without ironing:

Crash + streaks:

Streaks:

Thanks for your input!

Best Answer by Adam_pres:

@daryl-2

I've found that increasing your infill % (30% plus) helps with ironing. The top surface needs to be perfectly level for ironing. If only 10% infill then the top layer will sag and the ironing pass will miss it. Also same if your bridging you need lots of support .

Also helps to have at least 5 top layers.

Correct extrusion multiplier calibration is a must.

RE: Help with ironing?

I tried ironing for the first time today using the defaults in Prusa Slicer, just turning on ironing and specifying all top surfaces. I also have some places that look great and others that are un-ironed. I'm hoping someone with some experience will help us!

RE: Help with ironing?

I guess we are the only ones using ironing. I'll run some experiments and see if it can be improved...

RE: Help with ironing?

@daryl-2

I've found that increasing your infill % (30% plus) helps with ironing. The top surface needs to be perfectly level for ironing. If only 10% infill then the top layer will sag and the ironing pass will miss it. Also same if your bridging you need lots of support .

Also helps to have at least 5 top layers.

Correct extrusion multiplier calibration is a must.

RE: Help with ironing?

@adam_pres

Thanks for the tips, look forward to trying them out.

RE: Help with ironing?

I also had this issue and I use 35% ironing flow rate which seems to result in perfect ironing every time, while still not over-extruding. Tested with filaments.ca PLA and PETG.

I wonder why the default value is so low? Maybe it's sufficient if the bed is perfectly level and fully flat (not warped)? I found my own bed (MINI+) to not be perfectly flat. I assume that some micrometer-scale variance might prevent the nozzle from being low enough at some point to fully lay the filament on the surface..?

@Adam_pres Any tips for extrusion multiplier calibration?

RE: Help with ironing?

@fortinmike

Thanks for the tip,I’ll give that a try. Your bed level theory is interesting, there’s only so much that can be done with the data points from scanning the bed with super PINDA before the print starts.

I ran the bed leveling plug-in in Octoprint and was surprised how ‘warped’ it looks. Someday maybe I’ll try one of the manual leveling techniques.

RE: Help with ironing?

Thank you all for the input! I'm going to bump up the flow rate and I'll report back with my results.

RE: Help with ironing?

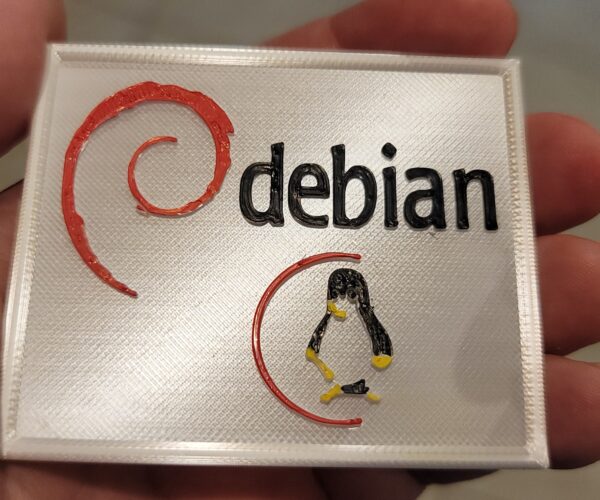

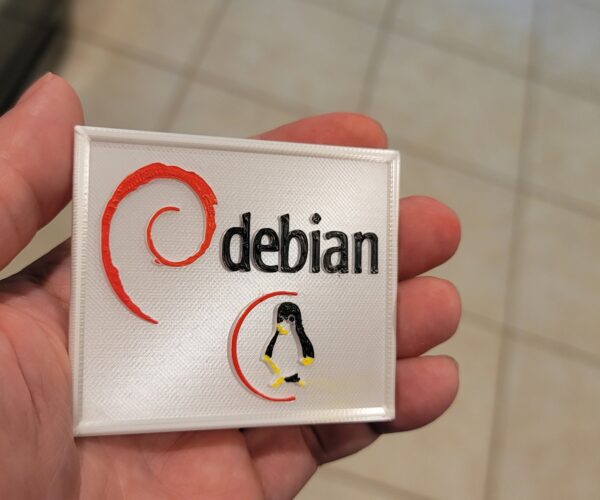

Wow. 35% was the trick. I'll print a few more with different values to see how good I can get it but that is great!

This is a silky PLA BTW and you can really see the shine.

RE: Help with ironing?

@daryl-2

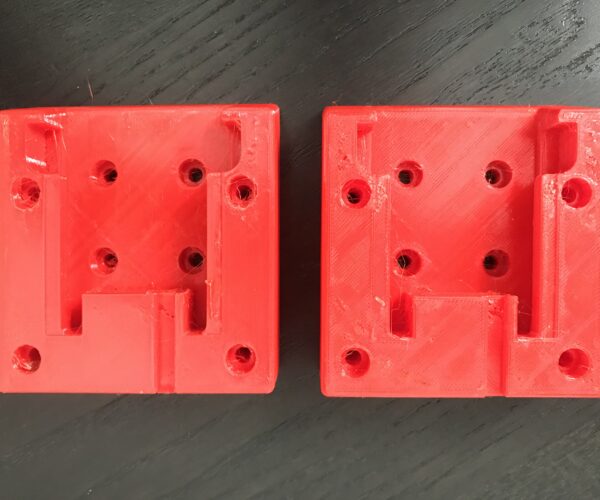

Funny, I designed one for a Milwaukee battery!

RE: Help with ironing?

Uh ohh. Something went wrong the last time I ironed a model. That Debian model I just posted may have accidentally been sliced WITHOUT ironing. I'm doing a test now at 5% increments to see what the magic value is.

Sorry about that.

RE: Help with ironing?

Funny, I remember ironing working much better (smoother) when I first started playing with it - but then I started to notice in the last few weeks that across all of our printers Mini and MK3S+ the ironing began looking underextruded or dry and scratchy. Maybe it's the current filament that is loaded that just shows the under-extrusion better. Regardless... I'm now running 30% flow with good results and could likely go 35%. Just thought I'd chime in and report that the increased flow is indeed helpful.

My ironed surface is way worse than un-ironed

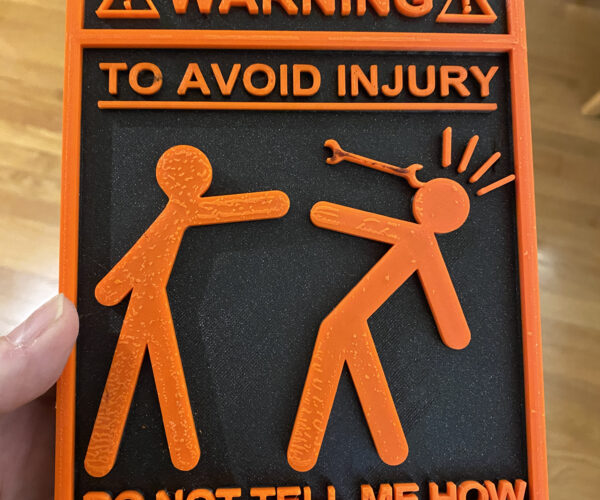

So decided to try ironing on my mk3S. Set it for the topmost layer only (so presumably the words). Obviously this is a color change. I have it set for 5 top layers. This is a brand new spool of Prusament PLA. Note I have a E3D Nozzle X if that matters. I am assuming the small amounts of black streaking is just some galaxy black that is built up around the nozzle is getting re-smeared down... But the surface of the people is terrible

Did you increase flow for ironing?

So decided to try ironing on my mk3S. Set it for the topmost layer only (so presumably the words). Obviously this is a color change. I have it set for 5 top layers. This is a brand new spool of Prusament PLA. Note I have a E3D Nozzle X if that matters.

Did you try the recommended 30-35% flow? I found that improves results significantly. Save your current 3MF project file, zip it up, and attach it to a reply here so we can see your part & settings and give better recommendations.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…