RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@robee

Which sock did you use on the Mini?

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

I made some of these: https://forum.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles/specific-silicon-socks-for-mini/

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@classic

I replaced the PTFE (which did shrink) and got it back up and running so I can print the mount for the Mosquito 🙂

Something worth noting: The Bondtech heatbreak rests upon the inner ledge of the heatsink. This means that if the PTFE shrinks, you can't just loosen the set screws and push the heatbreak/hotend assembly up to compensate.

This is something you can do with the origin heatbreak as it does not rest on that inner ledge. So you have a few mm of adjustment in the case of PTFE shrinkage.

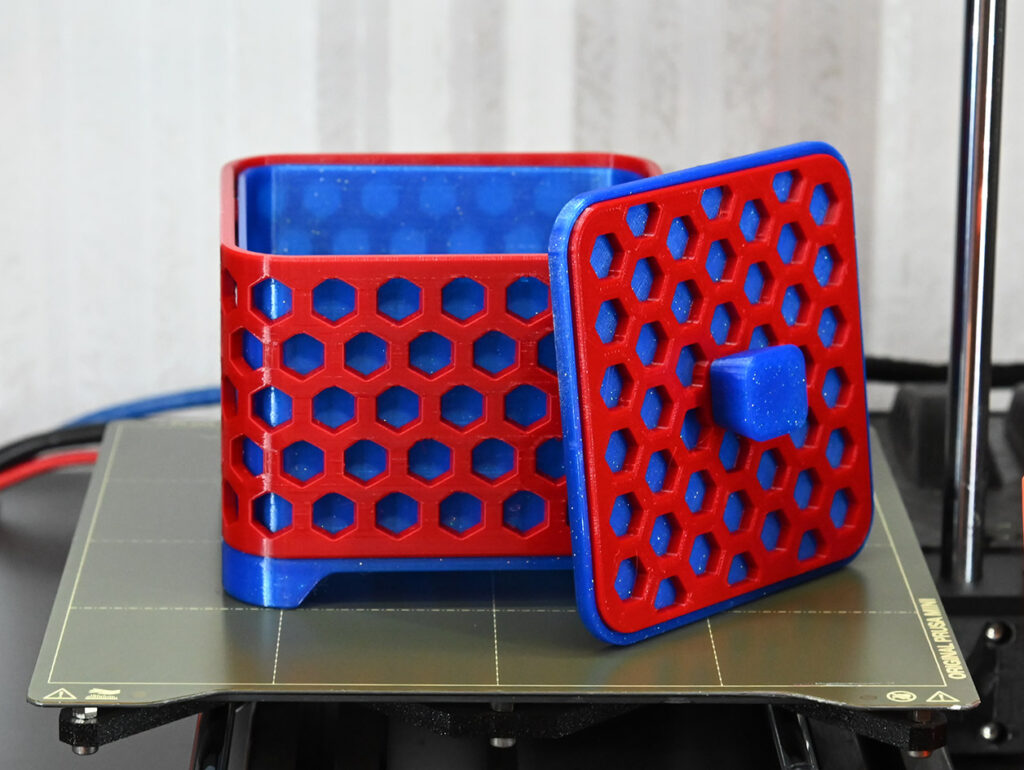

@benji, keep us posted on the mosquito hot end project! While what you say about the Bondtech is true, the PTFE tube is much shorter and most importantly, it does not extend into the hot zone. Even if there is a small gap, it is unlikely to cause the same type of problems that the stock heat sink does. For those considering the Bondtech, my stock mini would have choked on the outer red section of the hex box print below. There are too many retractions involved and heat creep would have been an issue. With the Bondtech, no problem.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

So like a lot of folks here , I did hte Bondtech upgrade and still had the same issues. MY PTFE tube did not shrink but still the problems persist. I have since started printing with PETG and have not had any problems. The problems so far only occure with PLA. So this must be heat creep right ? I can't even print a 10 minute job in PLA without the problem occuring.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@benji

T'is true, I really hate having to mod printers to get them working. For me printers are just a manufacturing tool so I want as plug and play as possible.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@classic

I replaced the PTFE (which did shrink) and got it back up and running so I can print the mount for the Mosquito 🙂

Something worth noting: The Bondtech heatbreak rests upon the inner ledge of the heatsink. This means that if the PTFE shrinks, you can't just loosen the set screws and push the heatbreak/hotend assembly up to compensate.

This is something you can do with the origin heatbreak as it does not rest on that inner ledge. So you have a few mm of adjustment in the case of PTFE shrinkage.

In the diagrams from Bondtech they showed that the PTFE tube resting further away from the heater block means that if a gap does arise then it shouldn't cause the same problems as the standard heatbreak since the filament isn't as melted back there. Fingers crossed this is true!

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

So like a lot of folks here , I did hte Bondtech upgrade and still had the same issues. MY PTFE tube did not shrink but still the problems persist. I have since started printing with PETG and have not had any problems. The problems so far only occure with PLA. So this must be heat creep right ? I can't even print a 10 minute job in PLA without the problem occuring.

This sounds like it could be a problem with the hotend fan then, it sounds like it's running too slow hence why PETG works fine still but for PLA the heatcreep due to the lack of fan power is causing it to soften too high up and then jam. Have you mentioned this to customer support because they might be able to provide a fan replacement?

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

So like a lot of folks here , I did hte Bondtech upgrade and still had the same issues. MY PTFE tube did not shrink but still the problems persist. I have since started printing with PETG and have not had any problems. The problems so far only occure with PLA. So this must be heat creep right ? I can't even print a 10 minute job in PLA without the problem occuring.

This sounds like it could be a problem with the hotend fan then, it sounds like it's running too slow hence why PETG works fine still but for PLA the heatcreep due to the lack of fan power is causing it to soften too high up and then jam. Have you mentioned this to customer support because they might be able to provide a fan replacement?

I will do that now, good observation. thank oyu for the input.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@benji

T'is true, I really hate having to mod printers to get them working. For me printers are just a manufacturing tool so I want as plug and play as possible.

This is why I waited for the Mini as my first printer, I knew I didn't want to spend twice as much on a MK3, and I knew I didn't want to have to modify it a lot to make it useable. The bondtech heatbreak is the only thing I've had to do to improve the reliability of mine, so I think it's been the perfect choice. It's easy to forget how cheap the Mini is, I see people complaining it doesn't have the features of the MK3 but then that is more than twice the price.

There is probably just one little easy to fix thing wrong with most people's problematic Minis, but trying to find out what that one thing actually is can be a very unfun experience.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

So like a lot of folks here , I did hte Bondtech upgrade and still had the same issues. MY PTFE tube did not shrink but still the problems persist. I have since started printing with PETG and have not had any problems. The problems so far only occure with PLA. So this must be heat creep right ? I can't even print a 10 minute job in PLA without the problem occuring.

This sounds like it could be a problem with the hotend fan then, it sounds like it's running too slow hence why PETG works fine still but for PLA the heatcreep due to the lack of fan power is causing it to soften too high up and then jam. Have you mentioned this to customer support because they might be able to provide a fan replacement?

Support asked me to turn the fan off and try a print. It makes zero sense. It almost seems like they don't understand the issue.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

So like a lot of folks here , I did hte Bondtech upgrade and still had the same issues. MY PTFE tube did not shrink but still the problems persist. I have since started printing with PETG and have not had any problems. The problems so far only occure with PLA. So this must be heat creep right ? I can't even print a 10 minute job in PLA without the problem occuring.

This sounds like it could be a problem with the hotend fan then, it sounds like it's running too slow hence why PETG works fine still but for PLA the heatcreep due to the lack of fan power is causing it to soften too high up and then jam. Have you mentioned this to customer support because they might be able to provide a fan replacement?

Support asked me to turn the fan off and try a print. It makes zero sense. It almost seems like they don't understand the issue.

Yeah that is weird. Do they know it's PLA you were printing. Sounds like they might have suggested that thinking you were printing just PETG. Are you able to explain the situation to them and the possible underpowered fan causing the heatcreep?

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@benji

T'is true, I really hate having to mod printers to get them working. For me printers are just a manufacturing tool so I want as plug and play as possible.

This is why I waited for the Mini as my first printer, I knew I didn't want to spend twice as much on a MK3, and I knew I didn't want to have to modify it a lot to make it useable. The bondtech heatbreak is the only thing I've had to do to improve the reliability of mine, so I think it's been the perfect choice. It's easy to forget how cheap the Mini is, I see people complaining it doesn't have the features of the MK3 but then that is more than twice the price.

There is probably just one little easy to fix thing wrong with most people's problematic Minis, but trying to find out what that one thing actually is can be a very unfun experience.

Yep, the MK3S has the potential for way more problems to arise. I had one at launch and after a few months and only 1 or 2 successful prints I just sold it. Everything that it was meant to do, like layer shift compensation, auto bed levelling, filament detection, almost every feature didn't work and the quality of the prints with the inconsistent extrusion so awful compared to the MK2 I previously had and pretty much every other printer I had.

Hopefully the heatbreak problem is the only issue to worry about!

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Ive read none of the above comments, but I had similar problems. Turned out the extruder gear tension was way too tight on my build. Took it apart and the way I fixed it is with all my filaments one by one I did the following manual test.

Starting with your hardest filament and ending with your softest, usually a flex.

Tighten the gear tension, insert the filament manually, then with one finger hold the extruder gear and with the other hand pull the filament. Keep loosening the tension until it slips, then tighten it back up about 2 turns. Move on to the next filament.. etc etc.

In the end you'll end up with good tension for even the flex filaments. My tension surprisingly feels very loose, but yet it hasnt given me any problems since. And I had most of the ones you described above.

The only other recomendation I have is changing the extrusion rate. I found most of the prusa slicer presets to be on the high side. So slowing down your prints can help as well.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@accounts-1

Please describe what manually insert the filament means. I have only used Load Filament from the control panel.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@whmacintosh

With the printer off, remove the extruder from the printer, take it apart like you do when cleaning it. And when you put it back together first put the extruder gear and the tension gear back in place and perform the above adjustments. Then finish putting the rest back together.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

I too installed the bondtech heatbreak and it didn't fix it for me. I did have an issue getting the supplied bondtech PTFE tube to actually fit in, it just wouldn't go in so had to cut the stock one to size.

When reading this thread I think what I'm experiencing is because of the hotend also. Before I dismantle the hotend again and put in a new PTFE I'm going to try a few PETG prints see if there is a difference.

This brings back painful memories of my Raise 3D N1 also, which just couldn't print PLA without an issue, it took me months to fix the heat creep on that.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

I keep thinking I have fixed the underextrusion/clogging issues with my mini after it has been printing great for a few weeks. It always makes me pay dearly the first time I swap to something other than Prusament.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@accounts-1

What is the tensioning gear? Is it adjusted by the screw under the filament input feed?

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Just wanted to add my experience with this issue.

I had the same problems with jamming/clogging at the heat break. Mine started when I began printing prusament ASA over 4 hrs.

I found the heatbreak ptfe had shrinked and replaced with the spare provided with Mini. Unfortunately that one also shrank over the next few days.

I decided to try some different ptfe tubing and cut it to 45.4mm to compensate for any shrinkage.

I used Capricorn XS low friction ptfe. I picked it at random and just got lucky i think. I didn't make any other changes to the Mini besides adjusting the tensioner a little.

I am now printing Prusament ASA at 265C and Prusament PC Blend at 275C without issue. Longes PC blend print was 13hr48min. I am glad I tried it, totaly worth the $12usd for the tubing. I was considering the mosquito hotend but the price tag was a little steep for a fix for a brand new printer.

Hope this helps, I was super frustrated when I started having problems so it is a relief to have found a fix. (Its been about 3-4 weeks since i made the fix)

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

I just pulled my Bondtech PTFE liner out and it is 35mm versus the 35.3mm it is supposed to be. Has anyone else had the Bondtech Heatbreak offer shrink. Is .3mm enough to be concerned?