RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Curious if those of you that have installed the BondTech heat break are using the PID gcode recommended in the installation guide? The guide states: add M301 P13.54 I0.98 D46.58 to the start G-code in the slicer before the ; intro line.

is that line necessary? I don’t recall that being part of the install process originally.

What? There were instructions? 🙂 Seriously, no, I did not edit my PID settings. I just swapped it out.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

What? There were instructions? 🙂 Seriously, no, I did not edit my PID settings. I just swapped it out.

What are your results, is it worth the money?

Stock MK4S with FW 6.2.6

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

What? There were instructions? 🙂 Seriously, no, I did not edit my PID settings. I just swapped it out.

What are your results, is it worth the money?

I think it is well worth it. Makes it almost as good as an e3d for much lower cost. All my problems (title of this thread) are gone. It just works now. The way a Prusa should.

My printer worked great out of the box but after a few months I started experiencing the issues in the title of this thread. I think the shrinking PTFE tube others identified is very likely the culprit. The design Prusa introduced with the Mini requires the length to be perfect. The Bondtech design just brings you back to old proven technology which is more tolerant of variations with time (temprature, humidity, age).

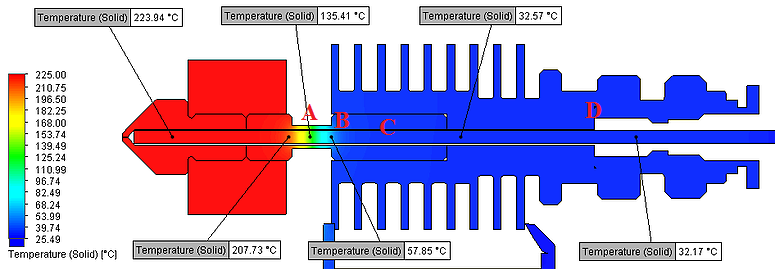

I found a pretty neat thermal analysis study someone did of e3d which is one of the most successful designs out there ( https://thomasannet.wixsite.com/portfolio/thermal-analysis-hotend ). Money shot below. The reduced neck (labeled "A") is important to keep the molten material out of the heat sink and nowhere near the PTFE interface at the point labeled "D". The Mini design not only allows more heat to flow into the heat sink because it doesn't constrict the tube at point A, but the PTFE interface is pushed all the way through the heat sink to about 6mm from the hotend (point "B") below. The Bondtech not only adds the missing thermal constriction so it looks more like the image at point A but also moves the PTFE inferface further away (point "C"). Not as far as the e3d but a good compromise to work with the rest of the Mini print head. There is now almost no chance of molten material reaching it so it doesn't matter if a gap develops at the PTFE interface with age.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Thank you, I have ordered the part and hope for the same results (with the explanation above I expect that it will) 🙂

Stock MK4S with FW 6.2.6

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

After my second hot end rebuild/adjust the mini ran great until last night. Jammed up good. Fortunately, I had the BondTech heat break and extruder just waiting for the occasion. Install went well and BondTech's instructions are excellent. The mini is currently printing without issue. Time will tell!

Bondtech Heat-break

After about 30 hrs of printing PLA and PETG the original nozzle jammed. The PTFE tube that came out was shorter than the Prusa replacement included with the printer, so rather than fighting it, I put in the Bondtech heat-break along with a Bondtech Dual Extruder. No problems since then. The heat-break is well worth the money IMHO. The extruder MAY BE, but I won’t know until I try to print some flexible filament.

Until Tictock mentioned it I hadn’t remembered to put the different PID commands in the slicer. Now that they are there I don’t see much difference, but I use a silicone sock on the nozzle and it evens out the temp fluctuations anyway.

oxygen: I thought the idea behind that breakout tab on the Mini’s control board was to prohibit unauthorized changes to the firmware without voiding the warranty???

Have you heard that Prusa going to modify the OEM firmware to allow some limited changes? The Bondtech dual extruder has some code changes it needs as well. Somehow, I can’t see Prusa modifying their firmware to make it easier to use aftermarket parts at the cost of extra complications with their warranty support.

S//

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Bondtech instructs you to use the PID values: P13.54 I0.98 D46.58

I decided to run my own autotune. I got this: P20.77 I2.22 D48.59

Quite different!

However, my hotend is wearing a sock, in turn requiring a different PID.

I do suggest you run your own autotune, whether you have a sock or not, with the command: M303 C8 D S200

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/

Auto tune?

How do you get the Mini to run auto tune? I would use Pronterface on an i3, but I thought that it doesn’t work on the Mini because of the locked controller board.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@vazovsky

Just user Pronterface:) The Mini can receive G-code obviously. It can't, however, save any settings sent via G-code to EEPROM (M500).

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Until Tictock mentioned it I hadn’t remembered to put the different PID commands in the slicer. N

S//

..for the record, it was actually @stevensmith who brought it to my attention

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Bondtech instructs you to use the PID values: P13.54 I0.98 D46.58

I decided to run my own autotune. I got this: P20.77 I2.22 D48.59Quite different!

However, my hotend is wearing a sock, in turn requiring a different PID.

I do suggest you run your own autotune, whether you have a sock or not, with the command: M303 C8 D S200

Interesting, I also have a sock on my MINI, When the heatbreak arrives and is mounted I'll inform you about the output of the M303 command

Stock MK4S with FW 6.2.6

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

[...]

oxygen: I thought the idea behind that breakout tab on the Mini’s control board was to prohibit unauthorized changes to the firmware without voiding the warranty???

You do not have to break anything to alter the start GCODE in your slicer it is just some extra GCODE that is sent to the printer before a printjob.

Stock MK4S with FW 6.2.6

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Bondtech instructs you to use the PID values: P13.54 I0.98 D46.58

I decided to run my own autotune. I got this: P20.77 I2.22 D48.59Quite different!

However, my hotend is wearing a sock, in turn requiring a different PID.

I do suggest you run your own autotune, whether you have a sock or not, with the command: M303 C8 D S200

PID autotune... I didn't recall reading about the PID setting when I installed my Bondtech heat-break, now I found that out and now you're telling me that I can even autotune this for my setup (my printer wears socks too 😂)... that's too much.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

After the BondTech heat break/extruder install, I've run prints with both the "stock" PID settings and the settings given on the website. I don't really see any difference. The temperature chart in Octoprint is rock steady for both. I think for now, I'll just run without them.

On a different note, I was curious what many of the stock settings are. I did a reset and then an M503 and captured the output. This includes the stock PID, filament extrusion lengths and e-steps among other things. Might be useful to some. I've attached it as a text file.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

I bit the bullet and bought one Bondtech heatbreak too. I don't have many issues with MINI, aside from noisy X idler and Live-Z flying up and down each print (discussed in different threads around here). I will replace it once I do bigger maintenance, I will upgrade plastic parts too as my MINI is still fully R1.

Anything I need to pay attention to during change? Is PTFE tube actually the same size as stock MINI? I see they don't do the quarter-turn pre-stressing of PTFE tube either.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Bondtech heat break PTFE tube is shorter = 35.3 mm. I made a shorter version of PTFE Tube Chamfer and Cut Jig for that.

Have a look at my models on Printables.com 😉

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

The replacement heatbreak arrived and is built into the printer -- did not use the M301 from Bondtech because I use a sock did my own M303 and put the values into the start GCODE. I printed the calibration cube with filament that never worked and this is the result -- I am happy

Stock MK4S with FW 6.2.6

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Fascinating stuff honestly, I haven't even gotten my mini yet and I'm already considering ordering the Bondtech heatbreak now, that way I don't have any hotend issues when it does arrive. I've had bad experiences with 3D printers in the past, so I'm a bit tempted to just cancel my order now, seeing as this is such a glaring flaw in the engineering of the hotend, and that Prusa has been silent on this for months. Has anybody reached out to support and asked about if they're looking into retooling?

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Bondtech heat break PTFE tube is shorter = 35.3 mm. I made a shorter version of PTFE Tube Chamfer and Cut Jig for that.

You have some nice models there 😲 simple yet useful. I bookmarked you.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@crawlerin

Thank you.

Most of my models is just things I needed at some point...

Easiest way to bookmark is to be a follower 🙂

Have a look at my models on Printables.com 😉