Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

All of the problems listed in the title and more can be (and probably are) caused by a wrongly assembled hotend or perhaps just simply a flawed hotend design. It can be frustrating to troubleshoot these problems as the symptoms vary and disappear & appear at different times. Additionally, the troubles may go away when switching to another filament only to return randomly later on or when swapping the filament again. Another misleading trait in the example of under/over extrusion is that it's very consistent when it comes to the areas of the print that display the problem. I had a stack of 10 Benchy bottoms showing extrusion issues in the exact same area.

Several people, myself including, have reseated the hotend, even rebuilt the hotend, in an attempt to fix the issue. However, the attempt resulted in failure or only a temporary fix with the problem manifesting itself again, perhaps this time as a different symptom.

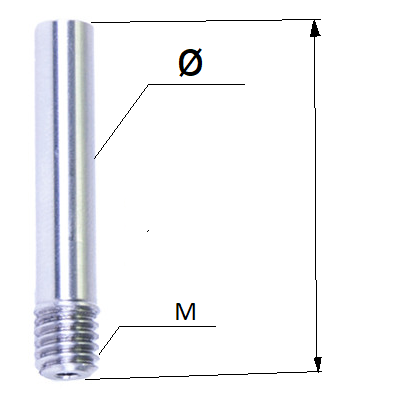

There is a right way to assemble the hotend and it's documented quite well by Prusa here: https://help.prusa3d.com/en/guide/how-to-change-a-heaterblock-heatbreak-mini_122769#123645 It requires assembly in the correct order, a precise pretension and precise torque, which in my opinion are not adhered to by Prusa themselves during pre-assembly at the factory. Not only must it be assembled tightly without any gaps, it cannot be assembled too tightly either.

I spent all of 3 minutes gathering a list of posts here on the official Mini forums which appear to all be related to what I have just described. It seems to be quite a widespread problem:

- https://forum.prusa3d.com/forum/how-do-i-print-this-printing-help/periodic-print-gaps-after-adjusting-head

- https://forum.prusa3d.com/forum/general-discussion-announcements-and-releases/sudden-under-extrusion-extruder-clicking-and-nozzle-temp-lower-than-what-is-shown/

- https://forum.prusa3d.com/forum/assembly-and-first-prints-troubleshooting/underextrusion-4

- https://forum.prusa3d.com/forum/general-discussion-announcements-and-releases/retracting-and-clicking/

- https://forum.prusa3d.com/forum/hardware-firmware-and-software-help/hot-end-assembly/

- https://forum.prusa3d.com/forum/hardware-firmware-and-software-help/prusa-mini-extrusion-e-steps-calibration-under-extrusion/

- https://forum.prusa3d.com/forum/hardware-firmware-and-software-help/extruder-clicking-2/

- https://forum.prusa3d.com/forum/hardware-firmware-and-software-help/hotend-temperature-issues-clogging-temperature-seems-to-be-lower-than-read-assembly-instructions-for-hotend/

- https://forum.prusa3d.com/forum/hardware-firmware-and-software-help/second-layer-first-half-under-extruded-and-another-over-extruded/

- https://forum.prusa3d.com/forum/how-do-i-print-this-printing-help/thin-walls-changing-thickness-on-layers-with-windows-ceiling-architecture/

- https://forum.prusa3d.com/forum/how-do-i-print-this-printing-help/extruder-will-not-advance-filament-during-print/

- https://forum.prusa3d.com/forum/assembly-and-first-prints-troubleshooting/extruder-failure-blockage/

- https://forum.prusa3d.com/forum/assembly-and-first-prints-troubleshooting/underextrusion-4/

- https://forum.prusa3d.com/forum/assembly-and-first-prints-troubleshooting/problems-with-clogged-nozzle/

- https://forum.prusa3d.com/forum/assembly-and-first-prints-troubleshooting/any-idea-what-causes-this-pilling-and-mess-on-the-first-layer/

- https://forum.prusa3d.com/forum/general-discussion-announcements-and-releases/prusa-mini-filament-frequently-jams-after-about-2-hours-of-printing/

- https://forum.prusa3d.com/forum/general-discussion-announcements-and-releases/problems-unloading-filament-jamming-in-ptfe-tube/

- I am sure there are more

I think it's fair to request a statement from Prusa Corp. regarding this. I think it's fair to demand a solution to this as well.

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

I don't agree with your analysis, some of those problems are with setting z height. I think we first have to establish whether these are indeed the same underlying issue. It would be nice if there was one common issue to fix, from my experience, I think it is unlikely.

Getting consistently good prints is a combination of lots of aspects being tuned correctly. I've been working through a few issues, it's a question of working through them one by one to get incrementally better prints.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

I don't agree with your analysis, some of those problems are with setting z height.

I do agree that many factors go into a well-tuned print. Also that a bad Z height can cause some of the issues I have outlined. However, the hotend assembly in the Mini absolutely can and does cause all of those issues and as far as I see, I just double checked, all of the linked posts in the OP are related to a poorly or incorrectly assembled hotend, not a bad Z height.

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

https://forum.prusa3d.com/forum/assembly-and-first-prints-troubleshooting/any-idea-what-causes-this-pilling-and-mess-on-the-first-layer/ was Z height, not related to hotend assembly.

Anyway, I'm out. Good luck.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@bobcousins

Unfortunately although OP of that post saw an improvement after calibrating Z, it appears that his issue was never fully resolved. The last suggestion was to lower printing speed. I do believe his problem is with the hotend assembly.

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

So I got my second Mini a week ago, neither my 1. Mini (delivered 12.12.) nor my new Mini has any of the described problems. I can use the cheapest PLA (under 10€/Kg) and I have never seen any problem.

I think I must have a different hotend than that you are describing.

Cheers

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@ulrike-b

Very glad to hear that. If you do start experiencing any problems and it turns out to be the extruder assembly, please let me know. I have seen it mention that the Mini works great for days or weeks and suddenly develops problems that are related to what I have described in the OP. However, I hope you don't 🙂

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Here is a video of iqless with the same problem:

Bondtech has released a potential fix to the problem. It's a new heatbreak:

https://www.bondtech.se/en/product/bondtech-heat-break-for-prusa-mini/

But it appears to be more delicate due to the thinner walls.

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

I think the follow up video is more instructive Prusa Mini Fix: Hot end sticking out too far. Around the 18:00 mark he outlines what he thinks is going on, and it makes sense to me. Particularly the demonstration pushing by hand, shows that after sitting for a while, the filament in the heat break expands and makes it difficult to extrude afterwards.

The interesting thing there is that he has Mini R1 and it was clearly adjusted wrong from the factory, but nevertheless worked "well enough", until other factors started to cause under-extrusion.

The fit of the PTFE liner seems quite critical. When I replaced mine with the spare, the old one was 42.4mm, a whole 1mm shorter than it should be. Does the PTFE liner creep and get compressed over time?

I noticed the Bondtech heatbreak yesterday when searching for a dual drive extruder. I might order both the extruder and heatbreak and see how that goes. I am also looking to replace the PTFE liner. I have never been a fan of plastic parts in my hotend.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@bobcousins

But what is the point in buying a Prusa printer that needs upgrades and 3rd party parts... Why not go to a cheaper printer if you are going to spend money on upgrades and time to fiddle with everything from scratch.

Really disappointed to see all these errors. This was supposed to be a printer for newbies and people who do not need to fiddle with initial settings or have any previous experience on 3D printing.

Nevertheless it is really interesting to see what other companies have come up with in order to overcome the problems of this printer.

Original Prusa Mini + Smooth PEI

Prusa Slicer 2.6.0

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Since I already bought one, for me your question is not relevant. I suggest discussion about which is the best value printer for newbies deserves it's own thread, please start one if you wish to discuss that.

I'm an engineer by profession. Fixing things is what I do!

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Being an engineer myself I can agree with you and I don't have any problem fixing something and getting to the root cause of the problem. This is where the joy lies. But this "product" was designed and advertised as something different and addressed to newcomers, that's all I am saying.

Anyway sorry for the off-topic. Looking forward to the results of the Bondtech dual drive extruder.

Original Prusa Mini + Smooth PEI

Prusa Slicer 2.6.0

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Actually I ordered a dual drive extruder from a vendor on Aliexpress. https://www.aliexpress.com/item/4000816286181.html

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

That's really interesting. Are you going to upgrade the heatbreak also?

Original Prusa Mini + Smooth PEI

Prusa Slicer 2.6.0

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

indeed, keep us posted.

Stock MK4S with FW 6.2.6

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Yup, I ordered a Bondtech heatbreak as well.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

Keep us posted. I read the install instructions for the heat break and I'm curious about the step where you are installing the assembled hot end and it states "push it all the way up." This is before the PTFE tube is installed and doesn't seem to jive with Prusa's instructions for assembly. I don't know if there is a 'stop' inside the heat sink that bondtech's heat break hits or not, but there doesn't seem to be a step where the heat break/ptfe tube is compressed against the brass fitting like Prusa indicates.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

@stevensmith

Prusa's instructions indeed want 1/4 turn of preload, Bondtech just says 'tighten the coupler'. I've emailed Bondtech asking for clarification. They also have a chamfer in the PTFE tube whereas Prusa has a flat end.

RE: Under extrusion? Over extrusion? Clicking? Pilling? Inconsistent layers? Clogging? Unloading problems? It's probably all the same core issue...

The Prusa Mini heatsink has a ledge inside the heatsink which prevents insertion of the heatbreak too far. The original heatbreak does not reset on this ledge, if it did, the 43.4mm PTFE tube stick out too much and the coupler would not be able to screw into the heatsink. I am sure this was by choice.

I believe the BondTech heatbreak is designed to sit flush up against the ledge and the provided PTFE tube is shorter to compensate for the difference.

I just started having extrusion problems again and had to reseat the heatbreak once more on my Mini and have decided to order the BondTech replacement as well. Should be here this week.

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/