Nozzle broke when trying to remove it (only had the printer exactly 1 week lol.

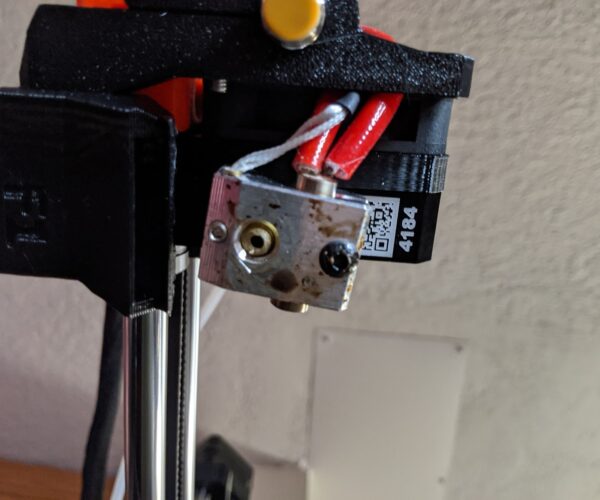

I had a nozzle sheer off when I tried to remove it to fix a clog.

Pre-heated to PETG, used the provided wrench and it just twisted right off.

The hot end is not available in the spareparts pages, I have submitted a help request to see if they can either replace it or let me buy a new one.

RE: Nozzle broke when trying to remove it (only had the printer exactly 1 week lol.

Have you been logged in when you scanned the spare parts? I can see the hotend heaterblock MINI for 11.99 €.

RE: Nozzle broke when trying to remove it (only had the printer exactly 1 week lol.

If you're in the US, you can get most spare parts at either Filastruder or PrintedSolid. Shipping will be faster and prices might be a bit lower.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Nozzle broke when trying to remove it (only had the printer exactly 1 week lol.

Did you manage to get out the rest of the nozzle? The issue could be, that you unsrewed the HOT nozle ,when all dimension increase due to thermal expansion.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Nozzle broke when trying to remove it (only had the printer exactly 1 week lol.

- It is recommended to unscrew the nozzle at 280°C.

- Could it be, that you screwed in the wrong direction?

RE: Nozzle broke when trying to remove it (only had the printer exactly 1 week lol.

Happened to me as well. Then I tired to set free the heating tube and termistor from the metal block, the plier slid, and ripped the wires from it. It was not covered by waranty, so I ordered new preassembled hotend from eshop.

RE: Nozzle broke when trying to remove it (only had the printer exactly 1 week lol.

I have not managed to free the threaded part.

I preheated to petg because that's what I had always done on the now u it's when they jam.

And yes I was trying to unscrew from the correct direction lol. I will take a look again maybe j just missed it.

RE: Nozzle broke when trying to remove it (only had the printer exactly 1 week lol.

Brass in aluminium, hmm, a small stud extractor may stretch the brass and damage the aluminium, I think you first need to remove the thermistor and heater cartridge and remove the heatbreak from the heater block, but if it's as stuck as your nozzle was, there could be trouble ahead.

I've removed damaged threaded brass air fittings from aluminium manifolds when there is no other way by very very carefully grinding away the middle up to almost the threads then managed to collapse the now very thin brass part with the thread in on itself into the now big hole through the middle. usually once you start, a set of long nose pliers will allow you to grab onto some of the brass and unscrew the rest, but I can honestly say, I've never tried it with brass in aluminium and hot melted filament thrown into the mix!.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Nozzle broke when trying to remove it (only had the printer exactly 1 week lol.

I managed to get the threads out using one of those reverse screws, and I have a new nozzle in there good as new.

Good job. I wasn't aware of the reverse screws, will have to check those out!

Be 100% sure you have a small gap between the nozzle hex and heater block after tightening at 285C. If not, you're likely to need another tear-down!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Nozzle broke when trying to remove it (only had the printer exactly 1 week lol.

Good result.

Do you have any details for your screw extractor you used, as there are so many different ones available.

This sort of information on this forum may well help others whom are in the same predicament, also did you have to heat the hot end whilst removing the remains of the nozzle.

Thanks.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Nozzle broke when trying to remove it (only had the printer exactly 1 week lol.

just a 2mm left hand screw i bought it at home depot.

RE: Nozzle broke when trying to remove it (only had the printer exactly 1 week lol.

@littleneutrino

Sorry to resurrect an old thread, but did you have the nozzle remains heated or cold when you used the reverse-thread screw to pull it out. If it was hot, how hot?

i broke a nozzle off as well the other day and my stripped screw extractor kit didn't work.

RE: Nozzle broke when trying to remove it (only had the printer exactly 1 week lol.

how to https://help.prusa3d.com/en/article/changing-replacing-the-nozzle-mini_134235I

could hopefully work also for remains

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Nozzle broke when trying to remove it (only had the printer exactly 1 week lol.

Thanks. Unfortunately, not in my case. There wasn't enough of the nozzle outside of the heat block for the socket to get hold of. It broke off with the only pieces still attached being too far up inside the heatblock.

RE: Nozzle broke when trying to remove it (only had the printer exactly 1 week lol.

@littleneutrino

I've had a similar issue with the nozzle breaking in the hotend, the fix for me was to use an 'Easy Out' drill bit for removing damaged screws.

https://www.bunnings.com.au/sutton-tools-no2-easy-out-extractor-screw-set_p6360081

This is a reverse threaded drill bit. You screw it in (in reverse) it bites, then turns the nozzle out.

Prusa Mini+ - Fw. 2.3.1 - PrusaSlicer 2.3.0 (Mac) - Filaments PLA / PLA+ / PETG.