Nothing sticks to textured sheet, not even PETG!

I'm having a hard time the textured sheet. I can't get PLA to stick to it to save my soul, PETG is iffy, ABS: not happening.

I've:

cleaned with 95% IPA

Cleaned with 99% IPA

Washed with dye free/scent free dishwashing soap, blue scour pad and hot water

only used gloves when touching the sheet, and I am just having hard time with it.

I have a good first layer height (this isn't my first rodeo, but first Prusa textured sheet), 75-85 temps with PETG (what I really want the textured bed for), slowed the print WAAAY down, and it still ever so barely makes it, sometimes. There is just no bed adhesion.

Is there a trick to these I'm missing?

RE: Nothing sticks to textured sheet, not even PETG!

Don't use your scour pad. It's contaminated. Always use fresh paper towels to wipe the sheets. Try again with soapy water and use a paper towel for drying too.

RE: Nothing sticks to textured sheet, not even PETG!

Do you have the smooth sheet as well? Have you recalibrated for the textured sheet.. its about 0.3mm thinner than the smooth, so you need to bring your Z height down loads to compensate

RE: Nothing sticks to textured sheet, not even PETG!

I use dishwasher soap and a scourer with my mk3 textured sheet, then wipe dry with a clean tissue, and never touch the sheet with my bare hands (only the edges to hold it). Perhaps your first layer isn't a close as it needs to be - post a picture.

Texy

RE: Nothing sticks to textured sheet, not even PETG!

Do you have the smooth sheet as well? Have you recalibrated for the textured sheet.. its about 0.3mm thinner than the smooth, so you need to bring your Z height down loads to compensate

This is spot on. My Z height is almost exactly 0.3mm difference when using the textured sheet versus the smooth sheet and I haven't any any problem getting PETG to stick (Prusament and Overture)

RE: Nothing sticks to textured sheet, not even PETG!

Yes, I have the smooth sheet as well.

I'll wash the PC sheet again with a paper towel, see if that helps. For the first layer, I have adjusted from barely touching the bed down to mega-squish levels and everywhere in between.

If it still doesn't work, I'll try the 3000 grit sandpaper on one side that I have read about.

RE: Nothing sticks to textured sheet, not even PETG!

My practices are not supported by Prusa: But this has worked for me.

1) wash textured pate with liquid dish soap and warm water.

2) Dry plate

3) LIGHTLY, rub fine 0000 steel wool around print surface using small circular motions until the raised PEI bumps have slightly lost their shine.

4) wash with liquid dish soap and warm water

5) Dry the plate

6) clean with 91-95% isopropyl alcohol. And before each print when the plate is cool.

This has worked for me and have no problems with PLA, PETG, ASA, and ABS

PETG generally like squish and slow on 1st layer.

Bed Temp I use.

PLA 60C-65C one or the other constant... higher value if it is really cold in the shop.

PETG 90C-95C

ABS and ASA 100C-110C constant

I have buildtak, PEI Smooth and Powder coated PEI on different build plates. Matter of fact. I use the powder coated plate 95% of the time. I have used the Buildtak Plate w/ some PVA glue stick on rare occasions with some difficult ABS and PETG prints to prevent edge lifting.

General rules I use on all plate surfaces.

PLA -normal squish

PETG a little more squish, slower speed on 1st layer with 0% fan... fan on 75% above 3rd layer,, start at 95C bed temp then drop to 90C after 3rd layer.

ABS Same squish as PETG but 110C first 3 layers and 100C after.

ASA the same as ABS except find better results of 35-45% fan after 3rd layer.

Sorry for the imprecise "squish" unit of measure but I do it by feel

Also, your mileage may vary and this my help you get started. I do not claim that this or any other parameters are the golden rule but, once you find your rules of practice just stick ( lol) with them.

- If you feel like trying my method of prepping the Powder Coated sheet, then go back to the initial methods you used to setup bed adhesion.

Hope this helps. Take a breath or two, try again, and have fun.

RE: Nothing sticks to textured sheet, not even PETG!

For the i3MK3S, for which I have both a smooth and textured sheet, I used a simplified version of tasmith2 's method. Basically just step 3 and some cleaning. Then use it only at high bed temperatures 80-90 deg. (so PETG). For PLA (50 deg.) I use the smooth sheet. Having only a smooth sheet for the Mini at the moment, I only print PLA.

There is probably not much wrong with the textured sheet as such, as the whole (?) Prusa print farm uses them!

Fred Jan

RE: Nothing sticks to textured sheet, not even PETG!

My practices are not supported by Prusa: But this has worked for me.

1) wash textured pate with liquid dish soap and warm water.

2) Dry plate

3) LIGHTLY, rub fine 0000 steel wool around print surface using small circular motions until the raised PEI bumps have slightly lost their shine.

4) wash with liquid dish soap and warm water

5) Dry the plate

6) clean with 91-95% isopropyl alcohol. And before each print when the plate is cool.

This has worked for me and have no problems with PLA, PETG, ASA, and ABS

PETG generally like squish and slow on 1st layer.

Bed Temp I use.

PLA 60C-65C one or the other constant... higher value if it is really cold in the shop.

PETG 90C-95C

ABS and ASA 100C-110C constant

I have buildtak, PEI Smooth and Powder coated PEI on different build plates. Matter of fact. I use the powder coated plate 95% of the time. I have used the Buildtak Plate w/ some PVA glue stick on rare occasions with some difficult ABS and PETG prints to prevent edge lifting.

General rules I use on all plate surfaces.

PLA -normal squish

PETG a little more squish, slower speed on 1st layer with 0% fan... fan on 75% above 3rd layer,, start at 95C bed temp then drop to 90C after 3rd layer.

ABS Same squish as PETG but 110C first 3 layers and 100C after.

ASA the same as ABS except find better results of 35-45% fan after 3rd layer.

Sorry for the imprecise "squish" unit of measure but I do it by feel

Also, your mileage may vary and this my help you get started. I do not claim that this or any other parameters are the golden rule but, once you find your rules of practice just stick ( lol) with them.

- If you feel like trying my method of prepping the Powder Coated sheet, then go back to the initial methods you used to setup bed adhesion.

Hope this helps. Take a breath or two, try again, and have fun.

I went through and "treated" the textured sheet with stainless steel wood, enough to get the shine off. After that, I washed with dish soap and HOT water very well. So far, so good. I've had good results with PETG (provided I keep the bed temp at 85-90), and even got a PLA print to stick with only minimal edge curling. I need to try ABS yet. It may be that I only use the smooth sheet for PLA, use the textured for PETG and maybe ABS. At least I have a sheet to reliably print with PETG, which will damage the smooth sheet.

RE: Nothing sticks to textured sheet, not even PETG!

I have several Prusa textured sheets for my MK3s and one for my MINI. I have had no problems with getting PETG to stick to the MK3s textured plates at all.

However, the MINI textured plate is different. Like you, when I first got it, I was unable to get anything to stick. I eventually tried a green 3M scouring pad (ScotchBrite) with hot soap and water. This has worked with PETG (though not with PLA yet - I haven't cared much since all I print with is PETG normally).

I tried getting support with this issue through chat and email. My experience so far with that is not great. Chat took over an hour to respond first then stopped responding all together. Email support resulted in them asking me to send the entire printer back and even scheduled a DHL pickup without my knowledge (DHL showed up at my door asking for the package 🤨 )

I know they say the plates are a consumable, and not warrantied. But one must be able to actually use it to consume it. Personally, I'm giving up ordering anything else or asking for any kind of support for 6 months when they may be caught up with orders.

RE: Nothing sticks to textured sheet, not even PETG!

[...] I know they say the plates are a consumable, and not warrantied. But one must be able to actually use it to consume it. Personally, I'm giving up ordering anything else or asking for any kind of support for 6 months when they may be caught up with orders.

They are consumables, but unless I'm mistaken, in the EU consumer protection laws cover products that are defective out of the box. I wish somebody would challenge Prusa on this.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Nothing sticks to textured sheet, not even PETG!

@tasmith2

Is correct! Did the steel wool on both my textured sheet for the MK3S and the Mini. Works great!

RE: Nothing sticks to textured sheet, not even PETG!

It's a shame someone doing the steel wool scrub does not have a USB microscope and can take pictures of the surface before and after the scrub, to see what has changed.

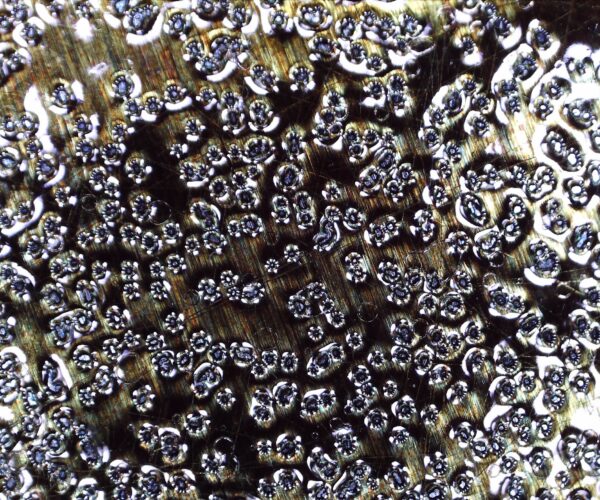

Here is my non scrubbed, original PRUSA textured sheet which PETG DOES stick to:

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Nothing sticks to textured sheet, not even PETG!

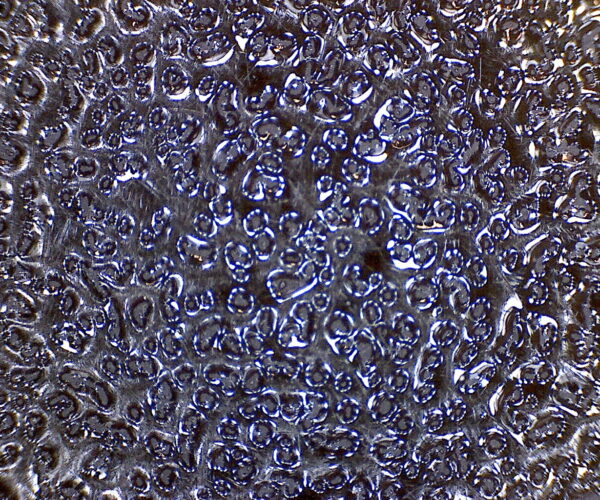

Oh for comparison here is a closeup of thekkiinngg textured sheet:

Notice how close it is to a PRUSA BH-15 as shown below:

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Nothing sticks to textured sheet, not even PETG!

This is the scrubbed side of my i3 MK3S textured sheet. PETG holds reasonable well, PLA doesn't. This might be more temperature than material related..

Greetings,

Fred Jan

RE: Nothing sticks to textured sheet, not even PETG!

I am fortunate I guess. PLA sticks great on both my scrubbed MK3 textured sheet and my scrubbed Mini textured sheet.

RE: Nothing sticks to textured sheet, not even PETG!

I also had issues getting PETG to stick to my textured build plate. As per some of the advice in the thread (thanks @shrikestorm !):

1. I hand washed my textured plate by hand with some warm water and dish soap. I didn't use a scouring pad or anything.

2. Dry it with some paper towels.

3. Wiped it down with 91% IPA

4. Did my first layer calibration, and things have been great!

I've had successful prints so far with 85°C first layer, and dropping it down to 80°C afterwards. Before cleaning the bed, I originally tried 70°C, but my prints kept coming off the textured sheet.

RE: Nothing sticks to textured sheet, not even PETG!

Whats the general consensus of the solution to this? I have finally got around to trying my textured bed and like many have reported, nothing sticks.

I have one on my MK3 and its fine... But on the Mini, nothing is stucking

My Z height on the smooth bed is -0.750 so I would expect my textured to be around -1.050.. But I have gone as low as -1.2 and can only just get filament to stuck but not for long.

A hot soap wash hasn't helped.. So it looks like I am going to have to get drastic with some wire wool or fine sand paper..

I am surprised its like this.. Prusa have surely mastered how to make the textured sheet and use them in their own factories to make the printers they sell. How can they simply not work? I am not sure whether to log a ticket before I do anything as perhaps they simply have a "bad" batch?

RE: Nothing sticks to textured sheet, not even PETG!

@jweaver

Are you sure you're not already too low? Print a first layer test. If it peels off during printing or you see a rough or "wavy" surface, then you are to low. If you hold the final piece into the light and see gaps between the lines you are too high.

It's easier to set up the correct value from the high side.

RE: Nothing sticks to textured sheet, not even PETG!

As i said, i have a Mk3 with both sheets so i know how to calibrate the first layer.

-1.0 was the point where it started to stuck (which stands to reason as the smooth sheet it -0.725 and the textured sheet is 0.3mm thinner, but from -1.00 to -1.20mm there is little difference. The layer looks ok (ie its flat bit not too flat) but it easily comes off... too easily.. certainly not enough adhesion to trust...