MINITEMP ERROR. Unable to resolve (cables are fine, resistance seems fine).

Had my Prusa Mini a couple of months now (so far, FATANSTIC), gone through 1.2-1.5KG of PETG, and generally very reliable (although a bit stringier than my MK3s+).

This week I started randomly getting the red screen reboot of death while printing from OctoPi. Disconnected the pi and printed from USB with the same result, but this time with better error codes indicating the MINITEMP had triggered.

I have tried:

- Printing from different USB sticks as well as directly from OctoPrint

- Ensuring the bed was heating up (tested by hand)

- Checking all cables (I really wiggled them around, pulled and pushed) and didn't get any 0/0 or error on the screen while printing

- Removing the probes during a print, which caused the error

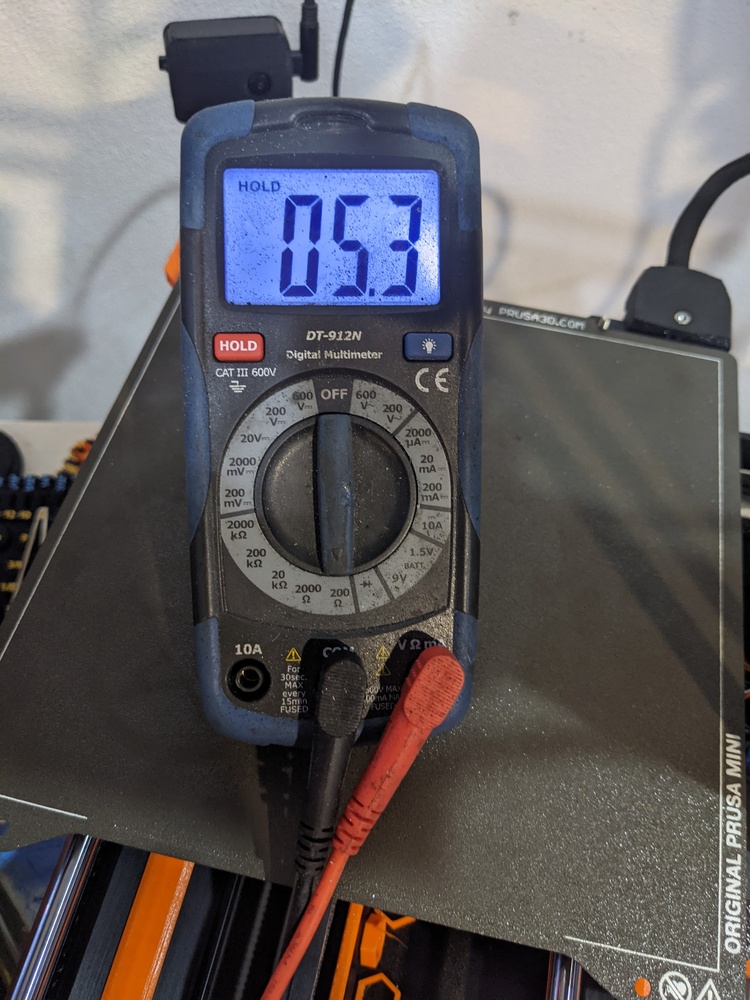

- Checked resistance of both probes and the heatbed as per instructions. They seem fine, images following

- Upgraded firmware and slicer (good to do anyway)

- Pulled out some of my hair

Keep getting the error, usually a couple of hours into a large print.

Obie-prusa-Kenobi, you are my only hope.

Error screen:

Bed probe resistance:

Hotend probe resistance:

Heater resistance:

Gone Fishin!

Obi Prusa Kenobi, is on holiday at the moment, I hope Joan of Nark can help.

generally Mintemp is caused by either...

1, Very cold Ambient temperatures (Below about 15C)

2, Poor connections, sometimes one pin is not correctly inserted into the connector plug and although the connector is inserted firmly, the one pin, makes a poor connection

3, intermittent connection in the wiring loom, ar wires flex, they age harden. and eventually break, this is a common issue on moving platforms like the heatbed. (ESPECIALLY if the printer is too close to the wall, and the wiring loom touches the wall when it moves backwards)

at first this tends to be an occasional problem, that get rapidly more common. (this can also be a problem if the thermistor wire was trapped somewhere or caused to bend in a localised manner

4, the thermistor could be failing... (Rare issue)

replacing the thermistor and cable assembly is the most obvious cure, but I guess you don't have a spare...

another option is to replace the section of cable that flexes. with a similar length of flexible wire

I have sacrifices a USB charger lead, and grafted it into the thermistor lead, making soldered and insulated joints under the heatbed, and inside the einsy case(I only have Mk3 style printers,) you would make the joint inside the Buddy board box.

the thermistor is not polarity conscious, nor does it carry high current, so as long as you connect the two wires through the new cable, you should be fine...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Might sacrifice a USB cable for science!

I read that soldering (along with wire length and gauge) can change resistance to the probe and show incorrect temperatures, but might be worth a try!

I wasn't able to find a fault jiggiling nor wiggiling the cables, so not entirely sure if that is even the issue.

I might purchase a spare thermocouple, just a shame the shipping to Australia is expensive 🙁

Hi Joel,

the thermistor resistance at 25C is 100,000 ohms, or there abouts.

a soldered joint has negligible resistance. so in this instance it is unlikely to make a measureable difference to the printer

I have repaired both the Heatbed thermistor wire and the extruder thermister wire, in this manner on one of other of my printers.

the Extruder goes to much higher temperatures, which causes the thermistor to go to much lower resistances, where the effect of additional resistance would be much more apparent, but once again, I have not witnessed any issues.

when I print overnight, I sometimes get a Mintemp Error (corrected) or similar message. because the printer finished and cooled down, and the low night time ambient temperature caused a legitimate Mintemp situation, which resolved itself as the morning warmed up!

I generally keep spare thermistors and spare heaters, plus 22AWG and 16AWG flexible silicone insulated wire, in my spares box.

22 awg, can replace all of the low power signals in the wires fatigue, such as thermistor, pinda, fan and motor wires,

16AWG will easily replace heater wires... keep hold of the high temperature sleeving by the heater block, this is much better heat resistance than heat shrink tubing, in that area.

repeated flexing eventually causes wires to fatigue, the flexible silicone wire lasts MUCH longer

this might not be your actual problem, but changing the wires will rule fractures out, as a possibility

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

IT WORKED!

Just touching base to say replacing the wires worked a treat. 🙂

Still not 100% sure where the breakage was and why it didn't occur regularly (I did a mighty jiggle test), but I'm happy none the less.

<3

with intermttent problems, fault location can be really difficult. it's often easiest to bite the bullet and replace the most likely culprit!,

If the fault goes away, you have prevented another failed print!

my most common fractured cable was the heatbed power cable, on early printers they were soldered onto the heatbed and that caused a focus point for stress concentration. i have had three prusa cables break, but since I started using Flexible silicone wires, none have broken!

I built the last three printers with silicone heatbed power wires from day one!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

fix

As Joan said, if it happens again, just replace the cable. I put a short piece of shrink wrap at the spots where it is likely to bend or add a piece nylon filament to reinforce it.

Just touching base to say replacing the wires worked a treat. 🙂

Still not 100% sure where the breakage was and why it didn't occur regularly (I did a mighty jiggle test), but I'm happy none the less.

<3

--------------------

Chuck H

3D Printer Review Blog

keep a spare

Having had two go now, I keep a spare thermistor & cable on hand. I've also made a new heat bed connector that incorporates some cable support/strain relief, which I'm hoping helps reduce the wire fractures as the bending isn't quite as pronounced as the heat bed moves forwards & back.

thermistor

I probably have a dozen of various manufactured thermistors. They seem to all function sufficiently.

Having had two go now, I keep a spare thermistor & cable on hand. I've also made a new heat bed connector that incorporates some cable support/strain relief, which I'm hoping helps reduce the wire fractures as the bending isn't quite as pronounced as the heat bed moves forwards & back.

--------------------

Chuck H

3D Printer Review Blog