inconsistent layers

I have some inconsistent surface issues with My Prusa Mini.

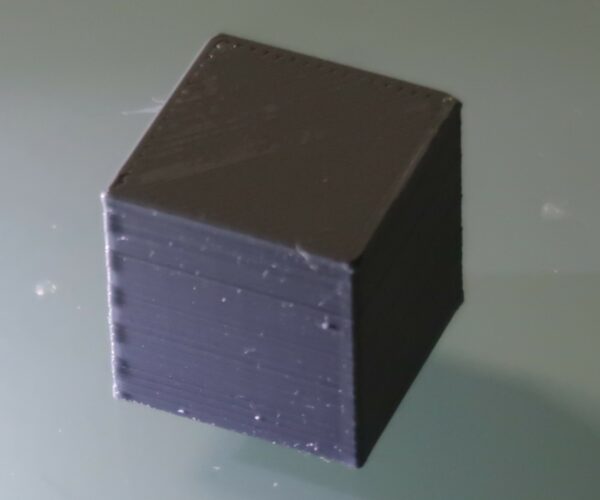

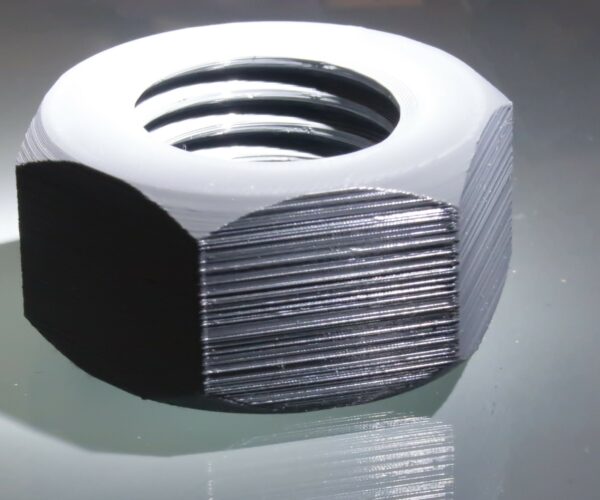

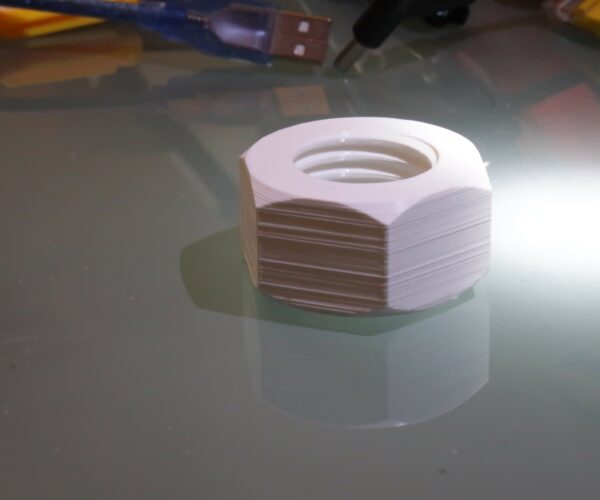

I printed a box and teh results were as I was used to: very good the layers were consistent and nice. Then a bit of life and 4 weeks later I print again, and the results are less than good. with somehow ugly surfaces as each layer seems to be a bit off. I thought that may be an issue with the quality of the filament (Fillamentum Iron Grey) as it was left outside maybe too long, and I don't have -yet- a box to dry them, so off I went and got a new fillamentum traffic White this time, and the first print after unsealing the box is also attached here:awful. All prints with the fillamentum PLA profile on my prusa slicer, printed at 0.20 quality. Slicer and firmware on the mini are the latest versions. I did take a look at the printer, increased the tension of the belts and did a general cleaning to no avail, nothing changed, same crap quality. The Printer has been always in the same place, so no issues with vibrations, though I also checked.

My mini has been printing from March regularly, but not constantly, I ordered in Dec 2019.

I did search the forum and saw nothing on this

Fillamentum Iron Grey

Fillamentum Iron Grey Fillamentum Iron Grey after a month

Fillamentum Iron Grey after a month This is the first print after opening the box

This is the first print after opening the box

RE: inconsistent layers

I am having the same issues. I have two of them and they face the same issue. I have no idea how to solve

RE: inconsistent layers

same with my mini.

thats why i searched the forum for a suitable solution, not going through 100 tweakings here and there...

but whats the solution to restore good quality printing?

RE: inconsistent layers

hard to check 1000 things for this quality loss...

maybe related to colder room temperatures in winter? -> https://forum.prusa3d.com/forum/hardware-firmware-and-software-help/too-cold-to-start/

or might be anything else. but i did not want to have such surprises, thats why i bought a prusa..but looks like i could have saved money and spent same time to optimize any other printers

RE: inconsistent layers

One of the benefits of buying from Prusa is their support. I'd suggest using the web chat on the e shop page to contact them and discussing it with them. Support will work through some checks and send replacement parts if necessary.

RE: inconsistent layers

@gordon-w

I wish that was the case. I had an issue with a loose brass nut on the PTFE tube and support told me that they fix the nuts with specialised machinery, which is not true. This forum -much quicker than the chat- provided the correct answer: they are auto-locking, no need for any machine.

As of the problem on the layers, I found a marginal improvement once I tighten the belts and all nuts and bolts I could access, but (very) far from original quality.

@Toz: it is cold outside but I am blessed with a decent heating system, temp indoors: 21 to 23C and that should be OK...

I will try anyway the support but that starts to be the end of my honeymoon with Prusa, tbh. If anyone finds the magic wand for this problem, I'd highly appreciate a word here...

RE: inconsistent layers

This might help:

Unscrew the brass fitting on top of the extruder

Loosen then 3 little screws that hold the heat break.

Put the heat break all up

Fasten the little screws

Screw the brass fitting back all the way down. It looks like I get better results. Try and let me know if it helps for you.

RE: inconsistent layers

@sptnq-com

i did this, than spend an hour in fiddling to calibrate the first layer. i had different results doing it with the mini-os and with a prusa-slicer file. i learned something, but my mini is not the "dont-care" workhorse i liked to buy from prusa... still have to fiddle today with experiments to see if i get some quality prints without to much tweaking 1 of 1000 settings...

@gordon-w

yes, there is support, but first i spended my extra money to a "prusa"-printer, not for support to get it better. simply printing without fiddling, i hoped ...but thats not so much the case for my mini, i guess ...

RE: inconsistent layers

I totally agree. I bought two minis for my office and they are a disappointment so far.

RE: inconsistent layers

@toz

but did this solved the issue of the layers for you? I am reluctant to go through that process (I did it a couple of times at the beginning) for a marginal benefit if at all. If it does solve it I'll do that. So far I've tried also to slow the speed (no change in quality really appreciated) experimented with flow multiplier and looked for some other less than perfectly tighten bolts... I may look into the nozzle but does anyone knows if nozzle-wear will cause this? I am running out of options... I am also bother by the edge behaviour on the cube below, a regular pattern I can't explain...

RE: inconsistent layers

I just did it yesterday and printed two flat disks for work. It seemed to be better but the disks where just 2mm in Z. To judge the wall quality, it needs to be higher. I had the impression that it looked better.

I know this regular pattern as well, I had them too.

RE: inconsistent layers

@ddx30

i tested some things, no one-for-all-solution found.

there is a thread with all my problems exactly described - also by others.

at the moment there seems not one solution.

it seems to me that there are distrubuted flaws in the mini: the hotend-construstion has architectural errors, there a quality issues in parts (minda/spuer-pinda not temp-compensation), firmware is improving (4.3. compensates different plate-heights for z-calibration: had to be there from the beginning!), extruder could be different, hotend-temp is false.....and other little things more for the prusa-techs than for an user.

i bought a prusa not for fiddling, but the mini seems not a market-ready product.

i have to follow some threads to see if there comes a solution.

what i observed (and the prusatester2020) is, that the prints well 1 time after a filament change.

nothing more than that (at least for me)..

RE: inconsistent layers

@ddx30

I have been having similar issues, same as you it all came out of the blue (I also have the bondtech heatbreak). To me it only happens with some filaments, or to be more concise, with some new batches of filament. In the pictures you can see a set of benchies I did. Both of them are PLA, both from PUSH Plastic (terracota and light gray) and the gray being the latest one printed (same gcode, same configuration, just changed the filament).

So far, I think it all has to do with the filament. I ordered a couple of spools from COEX and it is showing similar issues. I had to increase the temperature to 245 (yes, no kidding) to get a good print.

I think all Fillamentum, COEX and PUSH use Natureworks Ingeo as their PLA source, so it could be that the issue is coming from there ? Was there a change in the formulation somewhere this year ? Do you have an older spool to see if you have the same issues ?

RE: inconsistent layers

@aurru

That's a new idea. I actually do have some older filaments I had good prints, but I am skeptic as the two prints on my first post in grey come from the very same roll, just a couple of weeks apart. I had increased the temp to 225 with no really difference in the results, will also try higher...

@toz

really agree with you, I forked extra money to have a no-frills experience, and for a while it was so, now things seem to have gone south...

I also wrote to support, not that I expect miracles, but just to cover all bases...

oh and I am pure stock no upgrades or changes, just as it came from Prusa.

RE: inconsistent layers

Found this thread in which they are discussing our issue. They seem to be pointing towards the Bondtech heatbreak.

RE: inconsistent layers

If it is the filament, it is not acceptable . That would need to be advised prior purchase. I believe it has to do with pressure inside the nozzle/heatbreak but who knows!

RE: inconsistent layers

well, not that I got the solution but I found, for what is worth, that increasing the temp to 225C, and speed to 150 % (!) of the the preset in Prusaslicer, actually improves the finishing noticeable... I can't explain the reason, but that's the best I got in a while. Trying again today other models, see what happen...

RE: inconsistent layers

Let me give yiu hope. My Mini has standard Prusa parts. After one month of working flawlessly it started clicking, under extruding and giving poor results. After trying to clear up the hot end I contact Prusa support via chat. For me, the support was instant and thorough. After much interaction, including review of photos I sent, they suggested to bump up the temperature quite a bit. This worked surprisingly well.

Thinking how it worked before, I didn’t see increasing temperature as a permanent fix. I raised the hot end, inserted a new PTFE tube and spent ages looking down the nozzle. It was very hard to see but there was definitely a ring of filament in the nozzle. Several previous cold pulls had failed to remove it. With careful digging with a small drill and needles I managed to clear out the nozzle. After that I used pre heat for 3-5 minutes and it has printed perfectly in PLA and PETG of various brands (there was a time when Prusament was out of stock) ever since. The Super PINDA was not strictly necessary for me but I fitted one anyway. Once your Mini settles down it can become very stable. Do have another look down the hot end nozzle to check for a tiny blockage. If higher temperatures improve your prints it could well be that you have a blockage in your nozzle.

RE: inconsistent layers

Well, after many attempts to get this sorted and a few rather not helpful tips from Prusa support, The issue is solved by replacing the nozzle. However I can't say this is the solution as I have done enough things not to be able to attribute to a single one off them the outcome. I have replaced the nozzle and done a few more cold pulls with a clear filament I had around from Fillamentum, nothing particularly came out of those, but after that I changed the nozzle and attempted to replace the PTFE tube in the hotend, but looked perfectly fine to me so I put it back. I also loosen the idler screw even more than I had, to the point I think is actually not engaged any more. Result is that I printed again the cube and the walls are back to smooth and other print I have now in the machine is coming out good. Unfortunately I am now printing with clear filament and is very difficult to show the finishing in a picture, actually the best proof is touching it, but can't show this here, so you'll have to trust me. when I print again in some color I'll post here the result. the "corner" issue I had seems to be a different problem, so will ignore it for now...

Thanks everyone for their support, hope this helps someone...

RE: inconsistent layers

Hi! I had a very similar issue and i went through quite a lot of posts. I also tried to clean the nozzle, reseat hotend and clean the extuder gear+lead screw but nothing worked. My only work-around was increasing the print temperature to 245C and the result is somehow acceptable.

Today I finally solved my issue by relacing the PTFE tube - although it looks OK from outside. The heatbreak design of MINI resulted in a really high temperature on the PTFE tube and creep -- not only axially, but also radially. My PTFE tube has a zone near the entrance where the diameter is significantly larger than 2mm. I guess this created a small jamming region which at the end built up the pressure.

So my advice to anyone who is checking the post: try a new PTFE tube and the result might surprise you. The fix is not permanent since the high-temperature creep would eventually result in the deformation and we will have to replace the PTFE tube again. I guess i will just replace my PTFE tube every 2 months or so. Luckly it is pretty easy to cut and chamfer.