"Crunchy" or "Loose"-sounding Extruder?

Hi all,

I have a new minor issue (which may or not be an issue) on my extruder (I think). It sounds like something is loose or crunchy. The noise I am hearing seems to happen every time there is a reversal of the feeding stepper motor (i.e. during filament retractions). It has gotten louder over the last few prints.

I can't visibly see anything wrong or feel anything out of place. Here is a short video:

Does this noise sound familiar to anyone? Is it a cause for concern? Any suggestions on what to look for?

Thanks in advance,

-Iain

Best Answer by Bazim:

This can help: https://www.reddit.com/r/prusa3d/comments/kaellv/how_to_fix_clicking_extruder_on_the_mini/ I had exactly the same.

I don't recognise the sound but I suggest you check your X idler.

Cheerio,

RE:

This can help: https://www.reddit.com/r/prusa3d/comments/kaellv/how_to_fix_clicking_extruder_on_the_mini/ I had exactly the same.

RE: "Crunchy" or "Loose"-sounding Extruder?

Hi Bazim,

Thank you - I think this did the trick!

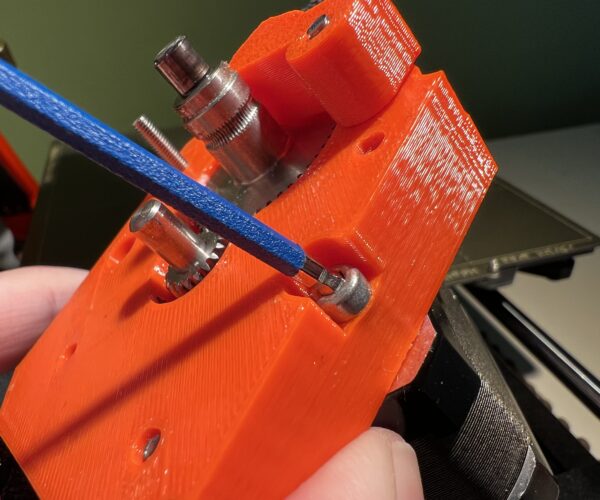

Before I pulled apart the extruder, I checked one other thing - I noticed a lot of lateral play (about 1 mm) on the extruder gear itself.

When I watch back this video now I can see that it almost looks like the end support bearing had been pushed back/out - you can see a very small bulge or gap toward the back of the extruder. I took care to press this back in.

I also put a small dab of grease on the teeth of the extruder gear. It is kind of a no-no to use two steel gears like this in design; for unlubricated operation, one should always be plastic.

It took 5 or 6 tries to find the "sweet spot". Too much force distorts the shaft upward and then when reassembled the gears will be meshing with far too much force.

Take care not to do what I did and overtighten the two screws securing the extruder stepper motor. The thin plastic on one of the two screws will deform outward. I would recommend only using the ball end of the allen wrench when tightening.