Bolt Factory issues in Blender 2.8

Hi folks,

If this is the wrong place to put this post, I apologise. I couldn't find anywhere on the Blender site to do with 3d printing, so I thought I'd try here. Please point me in the right direction if there is one here!

I decided I would have a go, as a beginner on Blender, at printing nuts and bolts on my i3 Mk3s. This will be a useful skill for some of my projects.

After some time of poor and slow progress, I discovered the Bolt factory add-on, and was in awe of the ease of producing stuff until I discovered that none of my nuts (sorry) would go further than 1/6 turn onto the supposedly matching bolt.

I'm using Sunlu PLA+ 1.75 filament with a base layer at 220 and subsequent layers at 202, which produces less stringiness for me, retaining with decent layer adhesion. Other settings are as the default PLA settings.

The picture shows one of my nuts done up as tight as it will go. When I try to tighten it further with pliars, the bolt snaps: this is not just a bit of "string" caught in the thread.

I have tried:-

- producing a bolt, duplicating it and then modifying the duplicate into a nut.

- Producing a nut, then producing an exact copy in Bolt factory but as a nut

I can't think of any other way to do it, but whichever way I try, they don't match up. I have yet to try Scaling the nut or or down in the Z axis to see if there is a fixed percentage error, but I wonder if anyone here has struggled with this, and if there's an answer already there

Advice will be gratefully received.

Many thanks

Pad

RE: Bolt Factory issues in Blender 2.8

I haven't used the bolt factory add on as yet but when you generated your bolts what sort of tolerance did you take into account ?

3D printers arent perfect and the stl models generated are made up of triangles/quads generally so can cut 'corners' especially on circles. Its usual with a 3d printer to run some form of tolerance test to determine what sort of leeway you have to have for parts to fit together. It will vary from printer to printer and can even vary for different filaments. There are plenty of tolerance tests out there you can download. For example on my printer if I need a 3mm hole that a M3 bolt will fit through without having to thread the plastic then I need to make it 3.1 -3.2mm in diameter.

If you want to model up your own test make a 10mm diameter cylinder roughly 15mm high. Then make a flat plate around 10mm thick. Model in several holes from 10mm to 10.6 at say 0.05 or 0.1 increments then print them out. You can now see which of the holes the cylinder fits through and what sort of fit each one gives.

You can do the same for a 10mm square tower with square holes too to get a feel of the difference between hole and rectangle tolerance too but generally circles need a bit more leeway. Or you can search thingiverse and download one 🙂

My Mk3 needs 0.1-0.15 depending on the shape but my cr10 needs 0.3-0.4 for most things. Remember if you ever release any of your models to others to think about other printers tolerances. They may be worse than what you are using.

RE: Bolt Factory issues in Blender 2.8

@neophyl

Thanks again.

You spend your life bailing me out of the sh1t!

I tried printing several nuts at +1% and -1% and then +/- 2% for the M8 setting, changing the vertical height only in slicer (bad choice, as it is far less easy to control).

In any case, one of the nuts didn't stick properly to the platter, and it all went to pot in a mass of hairy bits, so I'll try again, this time changing the dimensions on Blender, which is far more controllable.

I'll let you know how it goes.

Cheers,

Paddy.

RE: Bolt Factory issues in Blender 2.8

To be absolutely honest, I didn't think about tolerances until it didn't work. How daft is that? I just assumed that it'd be fine, and that Bolt Factory would simply work.

Of course different printers have different tolerances - it's obvious when you think about it. There is my problem for this one. I didn't think. Not until the problem was staring me in the face.

Some of the test prints are ongoing right now.

Pad

RE: Bolt Factory issues in Blender 2.8

Best practice for me is to scale the nut by 3-5% in the slicer in x/y direction. You have to keep the Z scale at 100%, otherwise you're deforming your screw.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Bolt Factory issues in Blender 2.8

@paddy_finn

what layer heights did you use and whic profile ? 0,2 mm or lower? For threads and nuts design I am using Fusion 36o with built in plugin using parameter modelling (this exports the exact shape) , and slicing it 0,15 mm and it goes very well. The smallest nut(screw combination of M5 went smoothly.

On your picture I see not very sharp edges, it could be done by design or printing?

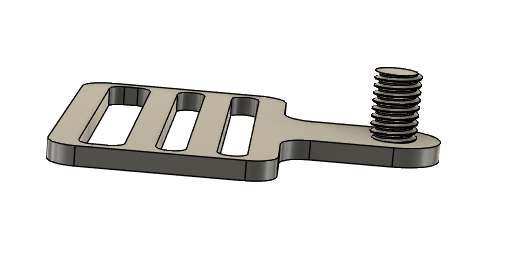

This is how it looks like in Fusion. In reality I am going to print it out right now

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Bolt Factory issues in Blender 2.8

@nikolai-r

Thanks. I assume that you are scaling the nut to increase its size by 3-5%?

I tried the scaling exercise from Neophyl, and with circular holes I could (just) drive the same-sized cylinder into the hole it created by Boolean subtration, but at 2.5% it was an easy fit. I assume 1% would work, but that's another print to do.

In Blender I can type the % change, but I haven't found a way to do that in Slicer - a % change typed in for any dimension seems to force a change in both others. I can adjust a single dimension using the mouse and dragging but it lacks accuracy and reproducibility.

Thanks

Pad

RE: Bolt Factory issues in Blender 2.8

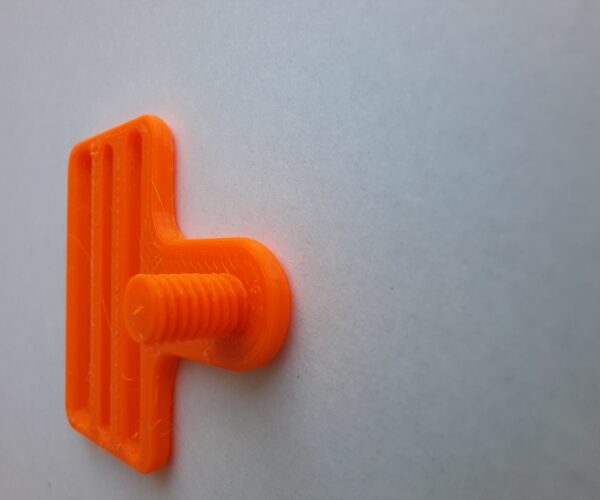

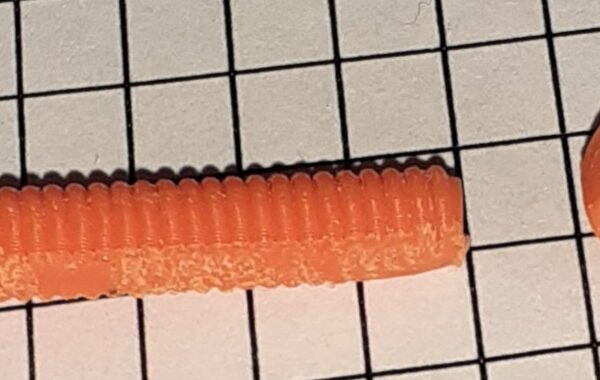

Here's the photo. Hairy little bugger, but the hairs are very fine. The increments show very clearly. This bolt had a 6mm outer diam and a 4mm inner diam, to try to enhance the thread well, but with no scaling between the nut and the bolt. It was still limited to 1/6 turn before it jammed.

The tests on scaling with nuts remain for tonight, and I'll report back.

Pad

RE: Bolt Factory issues in Blender 2.8

@paddy_finn

Correct. Scale up :). Default the scale is locked to all axes. Click on the lock icon to unlock it:

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Bolt Factory issues in Blender 2.8

Use a very quick pass with a blue flame or a heat gun to remove the hair like strings. They will just shrivel right up.

RE: Bolt Factory issues in Blender 2.8

Hi,

So heres a screw with matching bolts that I put into Slicer and resized in 0.5% increments from left to right. Front row resize in x-y only, rear row z only. Max resize was 2.5%

None of them would turn! So now it's a re check to make sure the nut and bolt really did match (got to cover all bases) and then repeat, changing all dimensions.

At least, that's.my next plan.

If you have other ideas, please let me know.

Pad

RE: Bolt Factory issues in Blender 2.8

@paddy_finn

The print quality doesn't look good. Either filament is bad or your printer has some issues. MK3 can do much better.

Anyway, try to print with 103%, 104%, 105%, 106% in X/Y direction only!, like already mentioned.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Bolt Factory issues in Blender 2.8

Yes, it was pretty poor.

That was printing with Sunlu PLA+ at 215 degrees for all layers.

I get far better results from 202. Adhesion is rubbish if the first layer is at 202, so that still goes down at 215.

I had a mad moment, and forgot to set it in Slicer.

Retry later.....

Pad

RE: Bolt Factory issues in Blender 2.8

@lichtjaeger

👍

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Bolt Factory issues in Blender 2.8

@lichtjaeger

That was a very timely tutorial video.

RE: Bolt Factory issues in Blender 2.8

@lichtjaeger

Thank you so much - that is amazing.

Not only covering offests, but techniques I have never heard of!

Soooooooo much to learn.

Pad

RE: Bolt Factory issues in Blender 2.8

Well, I did a new build of an M8 but and bolt following this guy's recommendation, and for the first time for one that screwed up properly.

I'll try that % of change for the others and see what happens.

Very exciting

Pad

RE: Bolt Factory issues in Blender 2.8

So... after the excitement of playing with the features mentioned in the video, I found that neither the 0.2 change nor a proportional reduction of that made any difference to my smaller nuts and bolts. So disappointing!

Above is a 22mm M4 bolt with a nut printed at a 6% x/y increase, as per nikolai-r, neophyl and Zoltan suggestions, and while I wouldn't describe it as a loose fit, the nut does fit finger-tight all the way up. This was printed at 215/200C in 0.09mm layers (0.2 for the first). I made the thread deeper than the default settings in Bolt Factory, and set the pitch at 0.85mm to improve separation of the thread while printing.

The thread seems miles better formed when I flatten off part of the head and thread of the bolt and print it flat on the platter.

The print is still a bit stringy, even printing with this better filament and at 200 degrees.

Could it be the nozzle - I've printed 850 meters of PLA and FLEX through it so far?

Pad