What is the poing of a skirt perimeter made of 3 layers ?

Hello,

I am just starting out with the Mini and PrusaSlicer. I do have some background using Cura with a CR10 and an Ultimaker3, as well as Repetier over USB on a Printrbot.

Coming into the Prusa ecosystem I am noticing that default settings in PrusaSlicer create a perimeter skirt made of 3 layers, and the same goes for at least some of the test prints from the USB contents (the test nut has it). And so far, this odd stacking of 3 thin lines has always failed.

This isn't a big issue as I can obviously remove that from the slicer settings and never have to worry about it, but still - what is the idea behind that ? I just can't imagine this skirt ever printing successfully, and thus often ending up being dragged onto the print causing a mess.

What am I missing here ?

RE: What is the poing of a skirt perimeter made of 3 layers ?

What am I missing here ?

Mostly that with proper live Z calibration and a clean steel sheet (scrubbed with hot water and dish washing soap) your skirt stick as well as anything else.

Having said that, I totally agree, 3 is too much. For a while I used 1 as the default, but now I'm using 2 layers as it makes it easier to remove.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: What is the poing of a skirt perimeter made of 3 layers ?

Hello !

I probably should have been more clear. I am not talking about a brim connected to a part in order to help with bed adhesion, but rather talking about the fact that there is an outer skirt line of 3 layers in the default settings and in the provided test files.

Now with other printer setups I've always perceived such looping skirts (looping a few times, but only on the first layer) as a handy last opportunity to adjust bed levelling. But here with Prusaslicer the default settings and examples all seem to suggest that doing a vertical skirt of 3 layers is a good idea. I'd like to understand what the point of it is ...

RE: What is the poing of a skirt perimeter made of 3 layers ?

Its simply to make them easier to remove from the pei sheet (especially the smooth one). thin stuff like the skirt flexes with the plater and so wont flex off like most models, so you usually end up using some form of scraper. 1 layer can be difficult for a scraper to catch on and so we get the 3 loops default.

RE: What is the poing of a skirt perimeter made of 3 layers ?

Neophyl is correct.

From Prusaslicer docs -

One-layer tall skirts can be difficult to remove from the print bed. Prusa profiles typically use a three-layers tall skirt for this reason.

RE:

Alright, thank you all for chiming in !

That does confirm that this is indeed the reasoning since the docs confirm it.

I personally completely disagree with it, as in my experience a thin one-layer line has never been of any difficulty to remove on any printer, at least with PLA, which the USB defaults are sliced for. And, the benefits of having a skirt loop outside the perimeter of a part (to check if a print is starting under good conditions) are IMHO far outweighed by the cons of a print potentiallyfailing because the nozzle ends up dragging along a skirt that gets detached (which has happened to me 2 times out of my first 3 prints, even after proper Z calibration).

Anyhow ! Thanks again for taking the time to chime in with the explanations. My question is now answered 🙂

RE: What is the poing of a skirt perimeter made of 3 layers ?

If your skirt is detaching then you have not mastered the 2 most important points of printing with a PRUSA printer, scrupulously cleaning the pei sheet and having a correctly dialled in live z setting. If you don’t master those 2 things then at some point you WILL get a print detaching and that will cause a world of hurt.

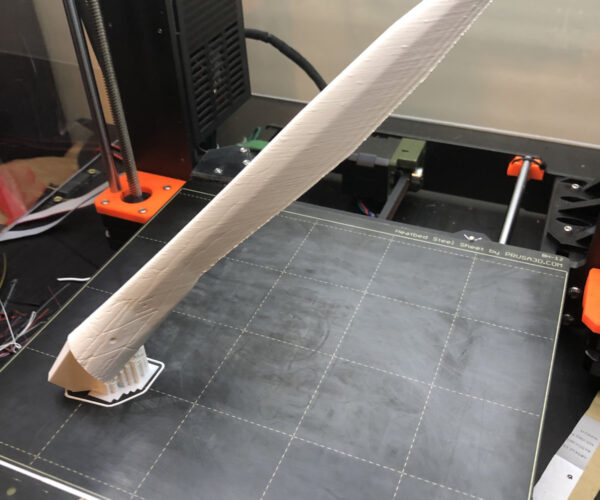

once you get it down though you can print stuff like the following 100% reliably

RE:

Of course - but the irony is that even on this photo, the skirt loop *did* indeed get detached 😀 Meaning that if the nozzle had done another pass over the area shown on the right of the picture (with the break in the loop), it would have been dragged along 🙂

In and of itself, the stacking of 3 layers of skirt does nothing to the adhesion of the whole piece - only the first layer is relevant. Unless the next two passes are seen as a test to check if the skirt resists the force of the nozzle going over it two times ? But that would contradict what the docs are saying (since according to the docs, the only reason for staking 3 vertical layers of skirt loop is to make it easily removable)

But hey, if it works for some, it works ! It's just very surprising coming from Cura, where default skirts are done literally the other way around (multiple concentric loops, as opposed to stacked loops. )

RE: What is the poing of a skirt perimeter made of 3 layers ?

No it didn't come loose by itself, that was me removing the other parts that it was around. You can also see the remains of a bit of support a bit behind. Also my skirt settings are a single layer high as I happen to also prefer a single loop too. Had to use by scraper on that anyway. That slice was done with a much older version of PS too, from back in 2019 so none of the newer support options. That's the beauty of settings though, you can change them to suit your personal taste. Just edit the profile and give it a custom name - done.

Here's a more recent pic, last year. That's almost full height diagonal on a MK3 (bottom corner to opposite top corner, only way to fit it without cutting). I never stop being impressed by the sheer holding ability of the smooth sheet. Its why I added the same setup on my Cr10.

RE: What is the poing of a skirt perimeter made of 3 layers ?

Well if anything, this thread shows that the maximum part length is actually much longer than the official 18cm measurement ! So that's good 🙂

(and as a matter of fact .... I also get a spare sheet myself, to retrofit onto a crumbling DIY Printrbot 🙂 )

RE: What is the poing of a skirt perimeter made of 3 layers ?

@neophyl was that orange part made just like that, without supports? 🤯

Mini+MK3S+XL 5 Tool

RE: What is the poing of a skirt perimeter made of 3 layers ?

Yes it was. The contact area is also less than it looks as there is a square 'hole' for a 6mm tactile switch that runs through the piece. You can get away with some quite steep angles once everything is dialled in.

On that particular part there's one small spot that could have done with support but its quite high off the bed and it bridged across (mostly) so the extra time to print small but high support tower wasn't worth it. I just ended up cutting off a single loose strand of filament with some wire snips and you basically couldn't tell.