Weird bumps/gaps when using ZIRO silk PLA

I've been using Overture PLA since I got my Mini+ a few weeks ago. I've also used Overture silk PLA and different colors of the regular PLA with no issues at all. I recently tried printing with ZIRO silk PLA since the Overture silk doesn't look shiny to me, and I got a couple of successful prints that don't look that great. The left piece in this image was printed with Overture Silk, and the one on the right using ZIRO silk PLA. I'm using the Prusa Slicer on a stock mini+, 0.25 layer height and 10% infill. Both pieces are printed using the same settings:

Nozzle temp: first layer 205, other layers 200.

Bed temp : 60

Retraction length: 3.2mm

Lift Z: 0.4mm

Everything else is set to generic PLA profile.

I also noticed that the ZIRO silk PLA is a bit runny when coming out of the nozzle, and usually looks much thicker than the Overture silk PLA. I tried adjusting the extrusion multiplier to both a higher and lower value, but noticed right away from the brim that the problem was getting worse.

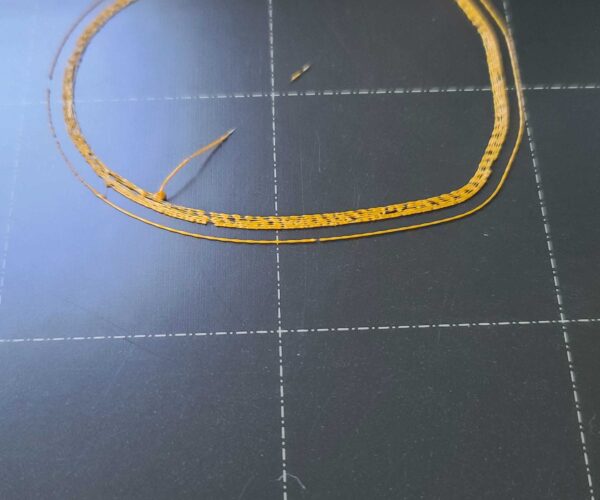

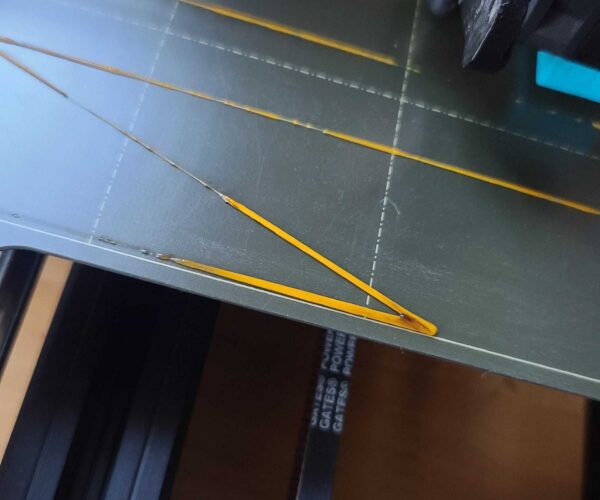

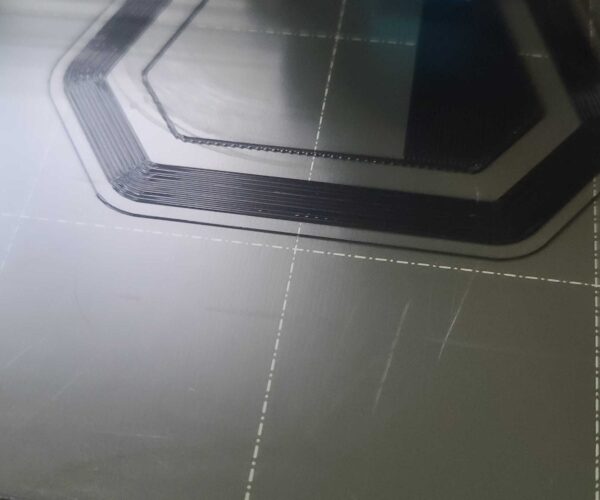

I also tried running the first layer calibration with ZIRO to check whether the z height was the issue for this specific brand, and it started extruding in bursts, so I stopped the test as I was worried about clogging. Here is what the test looked like at the point I stopped it. The lines were really hard to remove from the bed sheet, and they left a mark when I was able to get them off.

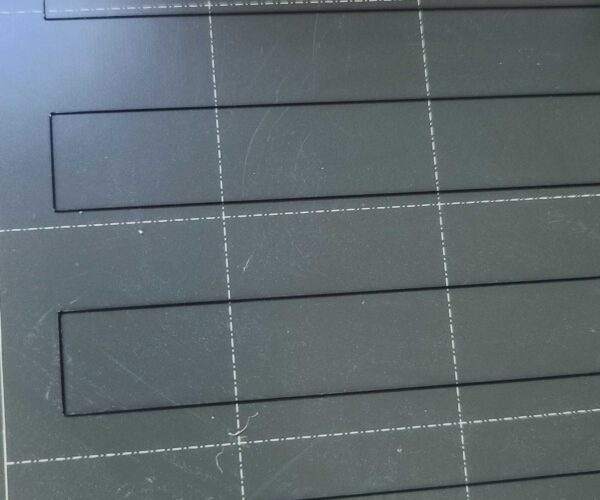

I switched back to the regular Overture PLA and ran the first layer calibration again and it looks great.

Why is this happening only when I use ZIRO? is it my print settings or could it be the filament itself (maybe a bad spool)? Any help would be appreciated as this is my first 3D printer and I'm still learning everything.

RE: Weird bumps/gaps when using ZIRO silk PLA

It's likely the filament. Silk filaments are somewhat known for being a little stubborn to print. You may or may not be able to tune it a bit for your specific roll, but don't stress it. I've come across some youtube videos that have some tips.

I used some eSun silk PLA the other night, it turned out decent because it was a round model, if it was something like a statue it would likely be stringy.

Regardless a filament dryer like a food dehydrator would be handy for all of your filament, good for drying descendants as well.

RE: Weird bumps/gaps when using ZIRO silk PLA

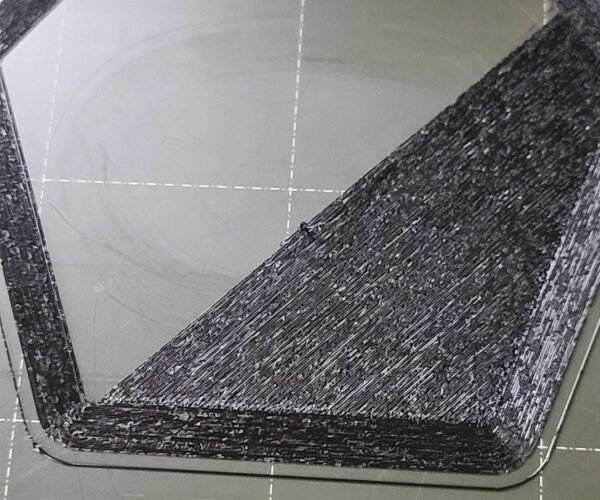

I've been experimenting for a few days and this seems to happen randomly with different filaments. I've turned in my settings for the silk PLA after my first post here and was able to get some really nice prints. But today the same issue was happening with my regular black Overture PLA which has always been really reliable. Here is what my first couple of prints today looked like:

The filament comes out really nice when purging and it creates a nice spiral pattern, but when printing it makes a small sizzling noise and the first layers looked like this. I unloaded/reloaded the filament a few times and tried using a red colored regular PLA which worked fine for the first few layers then ran into the same issue. I then switched back to the regular black PLA and it was printing fine without any adjustments to the printer or print settings.

I had already put both the red and black filaments in a food dehydrator at 45C and that didn't have any effect on my print until it randomly decided to start working properly.

I also tried adjusting my z-height and retraction settings, none of which seemed to help. Again, it just seems very random to me as I haven't been able to reproduce it or find a reliable solution every time.

Sizzling? It does sound like damp filament. Silk is particularly temperamental.

Filament absorbs water starting from the outer layers of the spool, in the dryer it loses water from the outside first too. Most damp filament only needs a couple of hours in the dryer but if it has been exposed for a long time it can take most of a day to dry. It's possible to partly dry a spool that then prints well for a little while until the deeper, still damp, layers begin to come off.

Cheerio,