RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@mike_mike

Mine started working much better after I made that adjustment too.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

then it is temp measure device error?

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@marc-c13

can you show how to measure? and your multimeter? is it infrared type? thank you

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

The multimeter that I have has a temperature probe (thermocouple) that I touched against the heat block itself.

As was discussed briefly above, I've not calibrated this, so I cannot necessarily trust the absolute value presented by the multimeter. Also, it's possible that the outer temperature of the heat block may be sufficiently different from the inner temperature.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

Brand new Prusa mini, 4.0.5

Gembird PLA+

Filament jams frequently. Unloading doesn't work almost at all. I suspect the bowden tube to be too precise.

Prusament seems OK.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@marek-3

"Welcome onboard" Mareck!… I faced same issue , and it is described here:

Then if you can't unload your filament, don't ''pull like a beast'' on it...you need to disassemble the whole stuff: PTFE, connectors, hotend… all

If you want all explanation about this issue, this guy made it clear: (you can go straight to 10:08):

https://www.youtube.com/watch?time_continue=722&v=D0QoeqRFd0U&feature=emb_logo

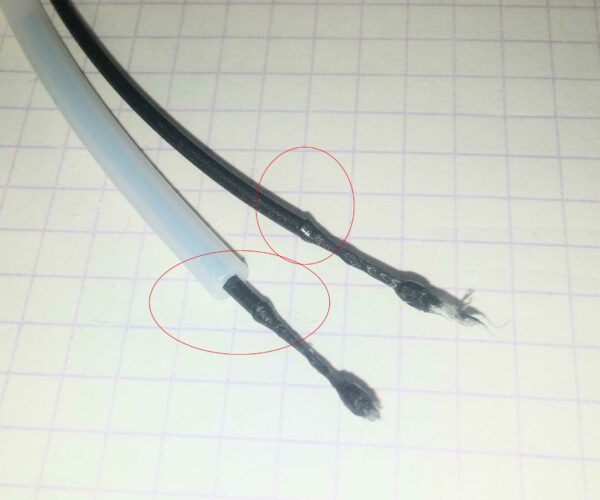

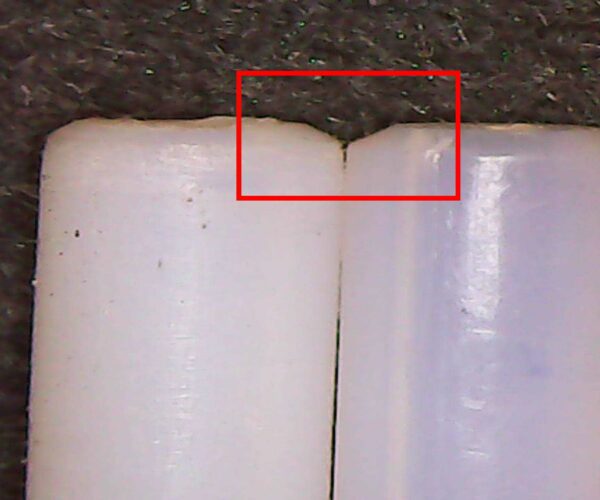

So after all disassembly you may observe this:

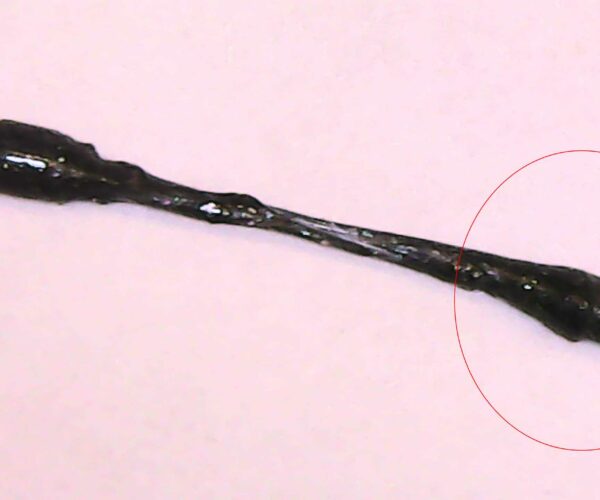

or zoomed here:

Therefore under extruder gear that will lead to this:

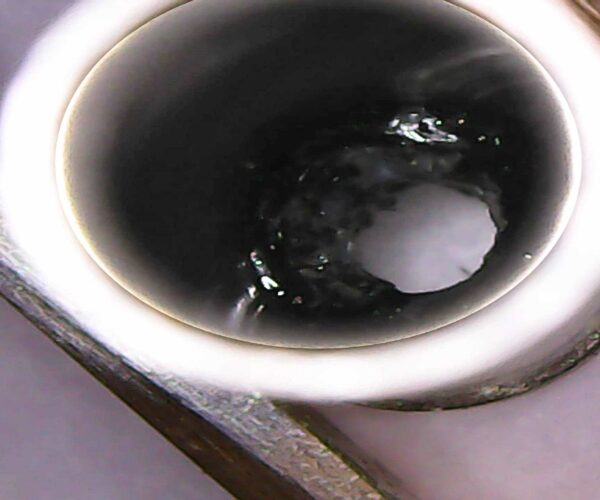

And inside the hotend stainless tube you will observe that:

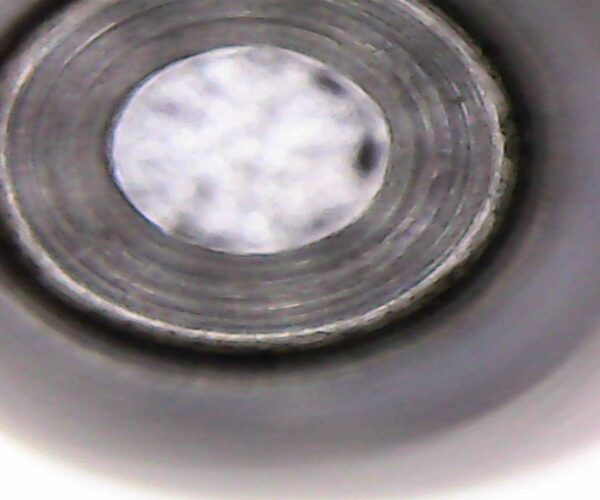

Which you will have to perfectly clean in order to recover this:

This is why it is sometime useful to have such cam:

Otherwise, if not perfectly clean, you will face the same issue...

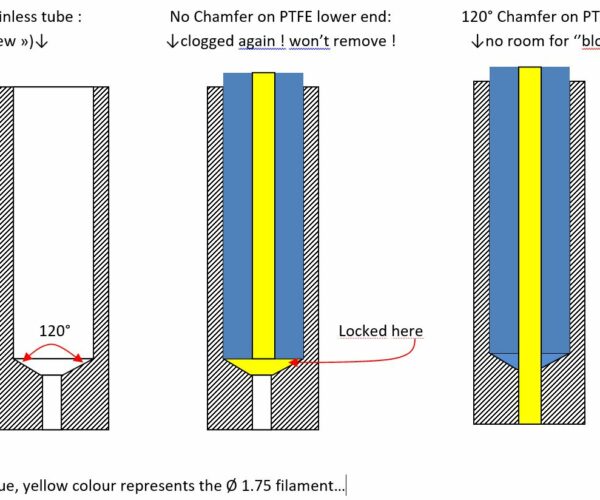

Pay attention with short PTFE internal hotend tube: it must have a chamfer 120° at least on 1 end, so it can perfectly seat on Stainless hotend tube internal bore end:

So refer to Prusa recommendations to solve this issue with above given link. There are several things to check, adjust, modify...

Hope somehow all above may help

Another info is that Bondtech already made a more robust solution. I bought it , received it, and on the way to install it

Regards

Sylvain

J'essaye de faire, mesurer et partager...plus pratique que théorique, peu de blabla, des résultats… La preuve incombe à celui qui affirme….en faisant et mesurant

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

I wonder how much testing Prusa do with non-Prusa filament, if any?

The main reason for filament jams seems to be the heatbreak position; the Prusa recommended settings seems to put in a marginal condition.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@bobcousins

Well not only a matter of heatbreak position in my case...

All my misery situations about under extrusion, filament locked in and so on happened to me with only PLA Prusament Galaxy black, same coil, ….so , not sure about others.

Except that I observed that the "asthmatic extruder" on Mini is not "strong enough" to push technical PLA from Volumic...which lead to horrific printed part aspects...meanwhile same PLA through Titan like direct extruder works like charm.

The "baby teeth" on Prusa Mini extruder gear can't manage/control the filament enough especially if filament hardness is a bit strong. Then you will observe plastic résidus on the extruder gear teeth….probably reason why you can lift up a kind of plastic cover which then let you to observe and eventually to blow those résidus away with some air pressure (which is even sometime not sufficient)

It was also fact that internal PTFE tube was 1 mm shorter than Prusa published specifications… and because I did not find another into the "spares kit" then I have to make one myself , cut into a longer PTFE spare...and to make the 120° chamfer (otherwise clogged issue will happen again..).

To bad this weakness into the bowden system, because otherwise this little 3D printer works pretty well and printed results are really great.

Hope it helps

J'essaye de faire, mesurer et partager...plus pratique que théorique, peu de blabla, des résultats… La preuve incombe à celui qui affirme….en faisant et mesurant

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@sylvain-t2

this detail is very cool, "120° at least on 1 end" for entry user like me some kind of this detail took me crazy.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@atomleef

Hello,

Not sure about your message: am I too much detailed into given info? However I inserted a photo related to this just below that sentence.

Please refer to links provided on my previous message (on April 12th). Otherwise it can be simplified to this (click on it to see full picture):

Hope I was a bit more clear here.

Best regards

Sylvain

J'essaye de faire, mesurer et partager...plus pratique que théorique, peu de blabla, des résultats… La preuve incombe à celui qui affirme….en faisant et mesurant

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

Same problem as everyone else: Mini does the first layer then clogs. Except I have two Minis and they both clog. Curiously, Mini #1 printed fine for a week before the problem showed up. I figured something had failed, so I assembled #2, updated the firmware, and it clogged right away. I tried raising the extruder on Mini#2, as per the fine video, but it still clogged. Reluctantly, I cranked up the temperature by 15°C and it's working. We've all had such good luck with the MK3S printers, so this problem is a real surprise. So was the fact that both boxes were missing all the M3 nuts for the filament stand. Some other weirdness with the Mini: it doesn't read gcodes properly from nested directories on the flash drive. I think this product was rushed to market prematurely. I wish I'd bought another MK3S instead of 2 Minis.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

Came here to just add a +1 for "raising the temperature to 235 C" fixed my identical issue.

I also disassembled my feeder housing and cleaned out the incredible amount of filament debris that had been chewed up and spit out.

I'm using the Prusa Galaxy Silver PLA spool that I ordered with the MINI. Can't believe this is such a widespread issue. I'm on the 4.0.5 firmware, is this temperature sensor incorrectness something that Prusa know about and can fix with firmware?

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

No, and no.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@sylvain-t2

Exactly the same issue I ran into with the same style clogs when I was printing with a few different rolls of Comgrow branded PLA! They always resulted in a plunger-like clog that prevents the filament from be retracted, resulting in a disassembly of PTFE fittings like you mentioned in order to remove the filament.

While I've had a few successful prints with my roll of Hatchbox PLA, I've since been printing only PETG until my Bondtech heatbreak arrives.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@nibmaker

Thanks for your info.

This Mini will make some happy guys in Bondtech! An important control is the length of this small PTFE tube and to make sure it is "locked" both ends, so it can not be lifted by filament retract action...otherwise this create this little space to create a clogged profile (which make unloading not possible)

There are also some upgrade kits available at Trianglelab (Aliexpress) where you can choose from revisited pair gears, up to Bondtech "cloned" extruder full system.

Also, if you have any suitable measurement devices: check the nozzle T° and compare to machine T° setup. I did this and real measured temperature is 3 to 5°C below my settings. So I increase nozzle temp. by 5°C each time. Some guys found up to 10 °C below temp. settings...

And I adjust the heatblock position into the ventirad (the 5mm Prusa specification)

So at least those are what I observed and corrected on mine so far. Maybe so other guys experiment "other weaknesses."

Works perfectly well since all those done...so I did not implement the Bondtech full solution so far, but I have it ready to go at next clogging.

Best regards

Sylvain

J'essaye de faire, mesurer et partager...plus pratique que théorique, peu de blabla, des résultats… La preuve incombe à celui qui affirme….en faisant et mesurant

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@rick-m12

I wish I could find out the size of the PTFE fittings for the tube. I contacted Prusa and they could not tell me the size.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@charlesnramsay

https://shop.prusa3d.com/en/mini/1084-hotend-ptfe-tube-mini.html

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@frankincell

I wish I could find out the size of the PTFE fittings for the tube. I contacted Prusa and they could not tell me the size.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@charlesnramsay

Hello,

Did you check this link?:

If your question is about internal PTFE tube length: 43.4mm ±0.1 mm

On my Mini, the original was found 1 mm shorter! So I replace it by cutting a part from a much longer PTFE tube roll and I made the 120° chamfer on one end using Dremel and abrasive disk.

Hope this could help

S.T.

J'essaye de faire, mesurer et partager...plus pratique que théorique, peu de blabla, des résultats… La preuve incombe à celui qui affirme….en faisant et mesurant

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

My two MINIs came from Prusa with 3 mm gaps at the bottoms of of the PTFE tube and nuts missing from both kits. You can imagine what monsters came up on the cold pulls after a bunch of print failures. The machines now work very well with the heater blocks adjusted upward and the temperature raised 10°C. But printers that come misadjusted are certainly not machines for a beginner. What has happened to quality control at Prusa?