RE: Printing multiple (same) parts at he same time using Prusa Slicer (sequential)

@hermannsw I'm excited to follow your results. You may also find some interesting details here:

In summary, he creates a fan-powered vent to allow the moisture to actually escape the enclosure. Merely heating a sealed box produced a "steamy" environment which didn't allow nearly as much moisture to be removed as a vented one.

Are you planning to print directly from your dry container? It seems like this is a requirement for prints which take more than a couple of hours, or the previously dried filament will just start getting wet again during a long print...

RE:

@ozarknerd Thanks for that video.

I will try with all 6 elements tomorrow (powered from constant voltage power supply) and see how much closer to 50° C I can get.

Did that, and after 2 hours 47.1°C were reached (with two 40°C, two 50°C and two 60°C heating elements):

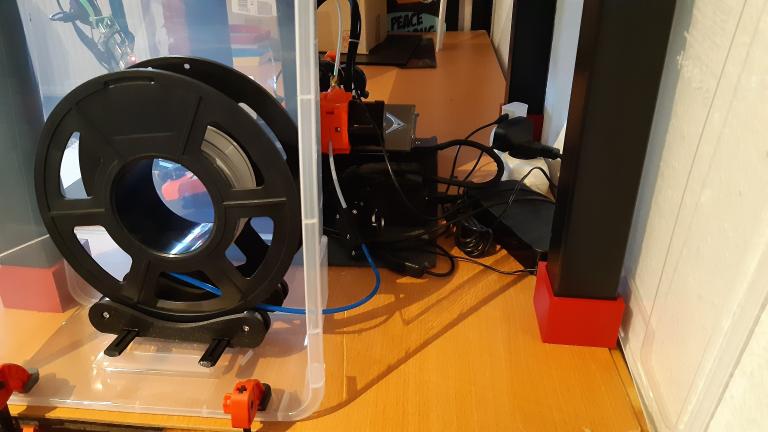

I think the glass case does transport away heat to surrounding to good, and a pure plastic box will do better. Also the PTFE tube @sandysasmita proposed arrived, which I will use instead of the 3Dprinted PLA part to guide filament through box hole:

RE:

you should use PTFE tube. Don't use that small pipe like the one you printed. It will create more friction an squeaky noise

Thank you, I did order PTFE tube yesterday, should arrive today:

https://www.amazon.de/gp/product/B07VHJ62RV/ref=ppx_yo_dt_b_asin_title_o01_s00

Today I made use of the (blue) PTFE I had ordered. I did move Prusa MINI+ to topmost Z position and determined the length of the tube from sticking in MINI+ filament sensor until 1cm inside Ikea Samla box through the hole I used sofar for my self printed guiding part. What happened when I printed first part was not what I expected. I expected blue PTFE tube guiding PLA from box to MINI+ to go somewhere into free space. I was surprised to see that blue PTFE tube ended up deep inside Samla box below spool by moving extruder down to heatbed — but it does its job in guiding PLA! Later I will fixate PTFE tube in Samla box hole so that only 1cm will look inside the box (and seal it so no air can pass). Box is open, and clamped to desk for this first test only:

I did record 1:49min smartphone video of cucumber jar holder 3Dprinting to get an idea how good/bad PTFE tube guiding works (images and audio). And it works well. Cucumber jar holder finished after 2.34h without issues, and blue PTFE tube is still inside MINI+ filament sensor, although there is no screw on that side to fixate it like the screw on other side for fixating sensor on MINI+ PTFE tube:

In order to see spool motion, I took every 100th frame from recorded 1280x720@30fps smartphone video with ffmpeg, scaled to 320x180 and created 20× faster than real animated gif from it (plays extracted frames at 6fps):