First day, success story

Howdy! Just wanted to give a quick summary of my first-day experience with the Original Prusa Mini. Technically, it arrived two days ago, but I only had time to put it together and today's the first chance I've had to tune and test it.

First, the one bad: I chimed in on another post here about the 15ºC mintemp situation, so I won't repeat it here. Suffice it to say that my first run experience being unexplained watchdog resets and crashes didn't fill me with confidence. Especially after coming to the forum and finding so many posts about build quality problems, loose screws, under extrusion, jams, etc. I was concerned that I unwittingly bought an experimental prototype, and I just don't have time to maintain a fussy printer. I own a competitors "mini" product that I got in 2015 and I was super impressed that it literally worked perfectly straight out of the box and every time thereafter. I don't think I've ever had a failed print that wasn't my fault, and in 5 years the only maintenance I've had to do is a single thermistor cable replacement. Recently I set up two MK3S machines in the makerspace at work so I got to see firsthand why so many people recommend Prusa. The MINI came along and I figured I'd jump in.. never hurts to have two 3D printers, and the future of my other machine's manufacturer still seems unclear to me.

Even though I have what I'd consider a good amount of 3D printing experience, because my previous printer came 100% preassembled and calibrated, I don't actually have much experience tuning and tweaking. The one thing I had to learn to do properly was Z adjustment, and just how much was needed. Having never done this before, the first layer calibration was hard to wrap my head around. I kept lowering and lowering and lowering it, without seeing much of a change, and worried about going too far and damaging the print bed. I don't have 100x zoom eyes, so I found the pictures in the manual hard to relate to. Is that 0.4mm line squished a little? I couldn't tell how far off it was until I printed the first layer of the sample Prusa logo and looked at it closely and did some searching. This article was exactly what I needed to see: https://help.prusa3d.com/en/article/first-layer-does-not-stick_2003. Mine looked just like the left, so I printed it again and live Z adjusted until I got "perfect". I had to go all the way to -1.230.

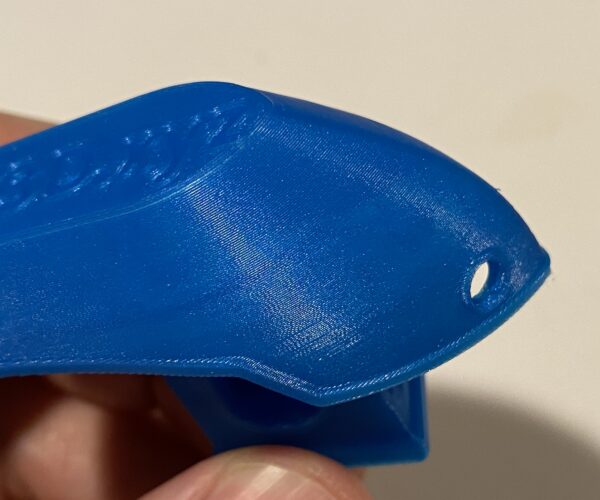

So finally getting to the point. Admittedly, I have only just finished my first full test print, but so far it looks like I have nothing to worry about. Now that the one parameter I had to dial in is dialed in, this Benchy came out far better than what I'm used to. I'm sure the expert tuners can get better, but I'm more than satisfied. The important thing is that I did not have to disassemble or rebuild this machine, and I'm reasonably confident now that it suffers from neither critical design flaws nor quality control issues.

Maybe this helps others who are browsing around here and getting the impression that MINI is not ready for prime time. I assume it's just the usual phenomenon of people who have no problems having no reason to post. So here's a post from someone who has had a positive experience.

As one small postscript, I did have trouble unloading filament from a cold start, but after reheating it, it worked the second time. So I'm considering that minor enough that it doesn't bother me.

RE: First day, success story

Nice post, thank you! 😀

RE: First day, success story

Thanks for the information … I am a beginner (waiting for my MINI), and your post is appreciated !!!