Extruder issues.

Get a perfect first layer calibration without fail.

as soon as I print anything with more than a couple layers, I get under extrusion. So far, here is what I've tried:

- three different brands of filament: Prusa, Matter Hackers, some Generic Chinese brand - same results

- cold pulls - multiple times

- replaced ptfe in hot end twice

- replaced nozzle

- Used acupuncture needle

- Cleaned extruder gear

- adjusted tension, from all the way tight to all the way loose while extrusion issue was happening - verified it feeds by running filament without it going to hot end

I don't know what else to do at this point. I'm considering buying a Bondtech dual drive extruder, but I don't know it will solve my problem.

currently my mini is a paperweight. ☹️

I'm not a mad scientist, I'm an angry engineer in training.

Pictures, top and bottom, of a failed print would help us diagnose.

Cheerio,

RE: Extruder issues.

i assume your prusa mini thermal paste is dry out, rebuild your heatbreak and reapply the thermal paste on the heatbreak like here at step 15 . you can use CPU thermal paste, a high performance thermal paste like "thermal grizzly kryonaut" would be better.

RE: Extruder issues.

I just had the same problem with my MINI+. I did all those things you did, 4 times. I finally got the machine to load and unload filament without getting stuck in the machine. I decided to try a print. It started OK then got a little thin. I let it go and it finally started printing normally. I think I had some filament that got some moisture in it. I did a couple of 20 hour prints on my MK3S+ and may have left the filament out too long. I store it on sealed boxes with Silica-Gel which keeps the humidity between 20 to 30%RH. I just started another print and it is coming out perfect. This machine seems very susceptible to filament that has been in humid atmosphere to long. Hope this helps.

RE: Extruder issues.

I'm in Arizona, which is a dry climate. I also store my filament in a sealed box with a 1 lb canister of silica gel, just to be safe. I don't think it is a moisture problem, but I bought a new filament that is still sealed that I will open and try next.

I'm also going to film a print and post it in case there is something that a member may catch that can provide insight. It printed for over a year with zero issues.

I'm not a mad scientist, I'm an angry engineer in training.

RE:

i assume your prusa mini thermal paste is dry out, rebuild your heatbreak and reapply the thermal paste on the heatbreak like here at step 15 . you can use CPU thermal paste, a high performance thermal paste like "thermal grizzly kryonaut" would be better.

That's an interesting idea, I'll have to see what that involves! thank you for the suggestion.

I'm not a mad scientist, I'm an angry engineer in training.

Pictures?

It's always worth drying the filament before trying anything drastic...

Cheerio,

RE: Extruder issues.

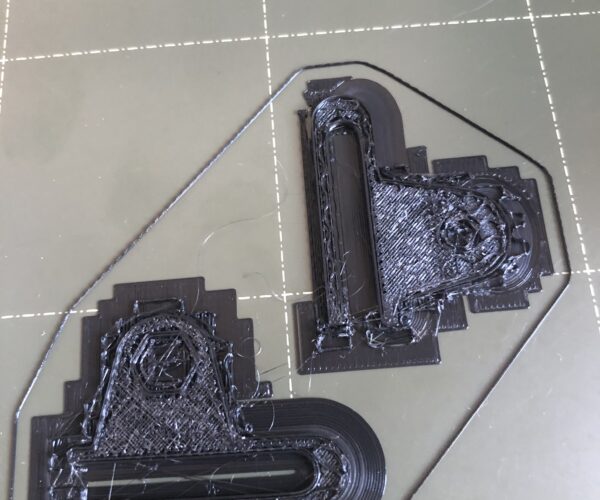

fill is under extruded, also, a lot of stringing.

I've replaced the extruder, print head, and ptfe tube for the hot end. I have not redone the thermal paste yet, just got it in - will try that next. The extruder seems to be working just find, leaving me to believe the issue is in the hot end itself.

I'm not a mad scientist, I'm an angry engineer in training.

Yup. Dry it.

Cheerio,

RE:

opened a brand-new vacuum sealed filament. same problems.

couldn't even get a calibration layer to print. Bag was sealed air tight. desiccant pack was inside. it had never been opened. So I tried a few things. took a piece of filament and tried to manually feed it into the hot end. to do this, unloaded filament, undid the ptfe tube and heated the nozzle to 215. then I inserted the filament and tried pushing it through. very difficult, almost impossible. then I raised the temp to 230 and it flowed nicely. reduced the temp to 225 and it still flowed nicely.

This is PLA, the same type of PLA I have made hundreds of successful prints with. At 221 it seemed to have problems. Now in all my original trouble shooting, I did switch to a hardened steel nozzle, as it was the only other nozzle I had. Maybe the heat profile is too different and I will switch back to the brass nozzle.

but it doesn't seem to be a moisture problem - since a brand-new still vacuum sealed package had the same issues. attached is the picture for the hand feed.

still seems to be something in the hot end where it is getting jammed up. Maybe the temperature probe is flaky?

I'm not a mad scientist, I'm an angry engineer in training.

You say you changed the nozzle, is it a genuine E3D V6 part?

Cheerio,