Printing TPU on the MK4

Hi all!

I've had great results printing 95A TPU with the MK3s+, printing on average at around 10MVS (granted, with a 0.6mm nozzle).

We've tried to print the same 95A TPU on the MK4, but can't reach anywhere close to the same speed - and even at super slow speeds, and the tension screws at their loosest settings, it still jams (extruder clicking sound).

We did do a vase-mode speed test where I just increased the MVS throughout the print using GCode insertions, and it managed to print the whole thing with no issues. So we're getting really mixed results. As far as I can tell, retraction is fully turned off too.

I'm not really sure where to turn - I'd be disappointed if this brand new nextruder was unable to print TPU at the same level as the old one... We put a pretty big investment of buying a bunch of MK4's for printing a large amount of TPU - so it's pretty important we get this working.

Anyone got any ideas?

RE: Printing TPU on the MK4

Hi all,

In a similar vein, I can't load 85A TPU on the MK4. It just jams up in the Nextruder gear. I printed it just fine on my MK2.5s. Is there a trick to getting it to load?

Paulin.

RE:

I printed a 3DBenchy in Amazon Basics TPU (98A) and it printed beautifully using the Prusa supplied "AmazonBasics TPU @MK4" profile.

But I tried my first Ninjaflex (85A) print on the MK4 today, and ran into problems.

First attempt, using the Prusa Ninjaflex profile: First layer started fine, but about 5 minutes into it I started hearing jamming noises (clicking) and saw extrusion problems. Canceled the print, opened the extruder latch and there was a long length (>50cm) of filament wadded up and jammed around and behind the extruder gear. Cleared that out.

Lowered the max volumetric speed to 2.5 (the Prusa profile default is 3.5, which should be fine, but...). Prepared for a second try.

Second attempt: No jamming problems. I let the print run up to about layer 8. BUT... Really bad oozing that was leaving artifacts at each layer start/end (see photo, there were two of these on the bed and both looked similar). I tried "tuning" the flow rate down during the print (which is why the layer pictured looks a little under-extruded), but that didn't help with the oozing / artifacts. The filament has been dried, and retraction in the default profile is 3.5mm @ 60mm/s (and I could visibly see retractions happening).

I'm not new to Ninjaflex, but am new to the MK4. My previous printer (Lulzbot w/Aerostruder 0.5mm nozzle) printed it really well, with no oozing. Guess I will start tweaking the retraction parameters to see if I can cut down the oozing but would love recommendations anyone here has. The default "NinjaTek NinjaFlex TPU @MK4" profile definitely isn't working well for me.

RE: Printing TPU on the MK4

Tried tweaking several parameters and still can't get rid of the oozing. But the JAMMING is worse -- really seems like there is just too much room in the area between the drive gear / idler and the tube to the nozzle.

Inspecting the "main plate" of my extruder assembly, it appears to have some minor defects. In particular, the lower triangular portion intended to constrain the filament was obviously printed very fast, and very hot, leading to some deviation from the design. Not sure that's enough to cause the jamming issues, but this is the area where "doubling over" and jamming of filament is occuring.

I'm printing a new "main plate" and the "PG Assembly Adapter" jig now, and will try to disassemble the extruder and replace the "main plate". Wish me luck!

RE:

I downloaded the mk4 printable parts from Printables.com and printed a new extruder "main plate" in Prusament PETG using the "0.15 Quality" setting. The filament guiding areas are much sharper (the factory-printed one had really blunt, "melted looking" corners from fast printing). I also printed the "PG Assembly Adapter" called for in the Nextruder assembly instructions.

I disassembled the extruder and replaced the "main plate". When reassembled, I ran the firmware "Gear Calibration" to make sure it passed, and then ran a PETG test print which came out perfect.

Then I loaded up some Ninjaflex 85A, again selected the Prusa-provided default "NinjaTek Ninjaflex TPU @MK4" profile, along with the built-in "0.20 quality" setting. The filament JAMMED again before finishing the first layer. ARGGGHHH. The filament was doubled over just below the drive gear, above the entrance to the nozzle tube.

Conclusion: The slightly mis-shaped details on the factory-printed "main plate" filament guides had nothing to do with the jamming.

I returned to adjusting other parameters, followed by test prints. Lots more jamming. Tried lower temps, and as expected that made the jamming worse (and did not help with the oozing, either). A higher temp (as expected) helped with the jamming and did not markedly increase the oozing.

After a lot of combinations, I settled on higher temp, slower speed (via reduced Max Volumetric parameter), and shorter retractions. This seems to have eliminated the jamming, as I have now successfully printed several 85A parts to completion with no jamming. Yay!

The oozing is still a problem, and the various retraction parameters I tried (shorter/longer, faster/slower, wiping, etc) had little impact. Adding some "negative restart" to the retractions did help with the extra material at layer start points. I'm now getting reasonably clean prints. At least they complete without jamming!

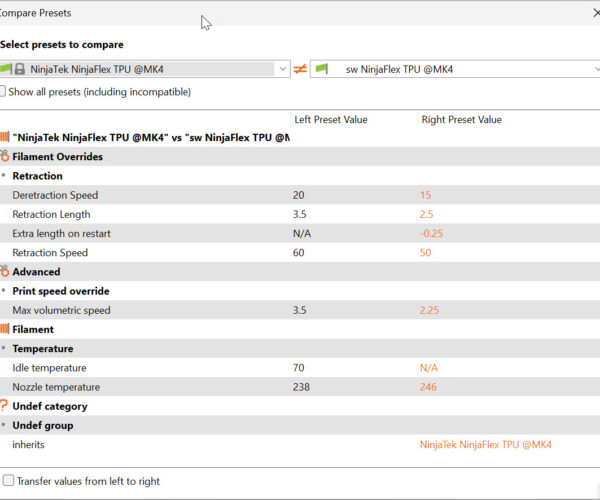

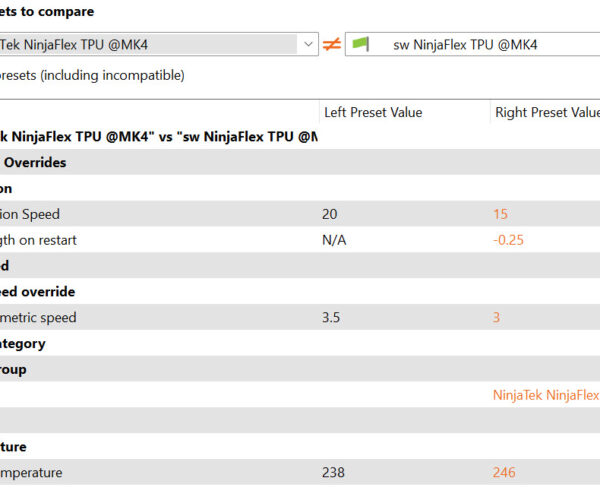

The settings I arrived at today are below. Definitely a "work in progress", so suggestions are welcome, but at least this eliminated the jamming and improved the ooze quite a bit compared to the default profile.

RE:

My guess is that the jamming happened mainly because of the 3.5mm retraction length of the default profile. This is too high for a direct drive extruder. When the molten filament in the upper part of the heater block moves up 3.5mm, it enters the cold(ish) bottom of the heatbreak and may get jammed there. As a rule, I never use retractions longer than 1.5mm. on any filament. Beware also of very fast retraction speeds. If you print TPU at 20-30mm/s don’t set a retraction speed faster than that.

RE: Printing TPU on the MK4

Really appreciate all the detailed insights guys - I'll do some testing over the next few days and see how it goes!

If anyone has any further insights I'm always interested hearing more!

I'm a tad disappointed that it appears to be slightly worse than the Mk3s+. I'm hoping with some settings tweaks I can bring it on par.

RE: Printing TPU on the MK4

Definitely looking for more testing and input from those with MK4's and soft (~85A/~40D or less) material! I'm sure the settings I posted can be improved; those were a "rough cut" where I made some pretty drastic "dart-board" changes to be sure the jamming was eliminated. I'll be trying to fine tune them -- in particular, I think the speed can be increased from the arbitrary 2.25 I used. But how much will require some trial & error to find the sweet spots.

Legacy knowledge says "fast retraction is bad with TPU!", and that used to be true in old slicers where retraction speed also dictated detraction speed. But today's slicers allow separate control of the detraction speed, and it is during detraction that flexibles are likely to buckle and jam if detraction is too fast. So, Retraction can be quite fast (50-60mm is fine) and that helps relieve pressure quickly, but Detraction needs to be slowed down a bit (the Prusa profile used 20mm/s, and that seems to work just fine).

Also, retraction length for TPU cannot be based on what is true for rigid filaments. Riddle: When is a 3mm retraction not really a 3mm retraction? Answer: When the filament is easily compressible, as NinjaFlex is!

When extruding, the filament is under pressure and gets compressed along the entire length between the drive gear and melt zone. The first bit of retraction just relieves that compression in the un-melted filament -- and may not move the filament end in the melt zone upward at all. Larger retractions are needed with 85A to compensate for that compressibility. (Do this test: Take a cold Mk4/XL nozzle and push a piece of 85A into the tube until it hits the nozzle. Now push a little harder, as if trying to extrude the filament, and another 2-3mm will disappear into the tube with ease. At that point, "retracting" 3mm barely moves the filament at the nozzle end, because it only relieves the compression in the tube).

RE: Printing TPU on the MK4

I did more testing/tweaking today, being more methodical and changing one parameter at a time between test prints (my earlier "shotgun" approach solved the jamming, but it wasn't clear which parameters were responsible or if the values were too extreme).

I have changed Max Volumetric Speed to 3mm^3/s (Prusa Ninjaflex default is 3.5), reverted the Retraction speed to 60mm/s as in Prusa's profile, and reverted the Retraction Length to 3.5mm as in Prusa's profile. No jamming, and print is looking much better (that 3.5mm retraction is really needed!).

I think the biggest improvement in terms of jamming was increasing the temperature, and perhaps reducing the detraction speed. I'll continue to home in on that with more testing. The negative restart value helps with oozing during moves (the 3.5mm retraction doesn't fully stop it), but also causes some slight under-extrusion at the start of the next layer. Need to find the best balance there.

But at this point, I am getting really clean prints (almost zero stringing, with very little ooze in travel moves) and am nearly at the speed of Prusa's default Ninjaflex profile (3mm^3/s vs 3.5). Relative to Prusa's default "NinjaTek NinjaFlex TPU @MK4" profile, which was jamming repeatedly, these are the only differences I still have in effect:

RE: Printing TPU on the MK4

@ScottW - Thanks for the revised profile. I'm definitely going to try it on my next TPU print to reduce the oozing/artifacts.

As for the loading of 85A filament, I continue to find it hit-and-miss; there's simply too much distance and not enough guidance for soft filaments to reliably hit the top of the tube. Next time, I'm going to try to hit the filament with a cold spray to temporarily stiffen a couple of inches of it when I feed it in. (Hopefully, the filament won't break when it goes over the gear 🙂

RE: Printing TPU on the MK4

I know what you mean about loading... I have not had problems with it hitting the top of the tube, BUT I do have problems pushing the 85A past the filament sensor. It hits that spring-loaded ball and just stops. Grasping the filament very close (a few mm) above the extruder and pushing helps, but then the filament sensor triggers and the gear starts turning before I can push the filament down to where the gear/idler catch it -- so then the priming/purging takes extra tries.

Spraying the filament with cold spray is a cool (pun intended) idea! Might just stiffen it up enough to make loading easy. Let us know how that works!

I'm still banging away at my profile... I was hoping to tweak just the Filament profile, and not have to mess with the Print profile, but I think the Print profile will need to be altered as well.

I was getting pretty clean prints just changing the Filament profile, mainly increasing the heat and slightly lowering the Volumetric Speed to eliminate the jamming. Then I tried printing something with some slight overhangs and had problems with the filament curling upward at corners. More fan and lowering the temp (which also meant lowering the speed further to avoid jams) did not entirely solve that. The only way I got rid of it was to lower the perimeter speeds in the Print profile. Still working on it, lots of failed tests in the dustbin and another one printing now!

@ScottW - Thanks for the revised profile. I'm definitely going to try it on my next TPU print to reduce the oozing/artifacts.

As for the loading of 85A filament, I continue to find it hit-and-miss; there's simply too much distance and not enough guidance for soft filaments to reliably hit the top of the tube. Next time, I'm going to try to hit the filament with a cold spray to temporarily stiffen a couple of inches of it when I feed it in. (Hopefully, the filament won't break when it goes over the gear 🙂

RE:

With some more testing completed, I am just going to end my effort with some observations and conclusions about printing Ninjaflex 85A on a MK4.

With the Prusa-provided "NinjaTek NinjaFlex TPU @MK4" profile, I had consistent filament jams. It is just trying to print to fast; the Max Volumetric Speed (MVS) is set at 3.5mm^3/s in that profile). Raising the temp from 238C to 246C and lowering the MVS to around 2.7 eliminated the jamming, and I had some fairly clean prints of simple items. When moving to more complex prints, particularly with overhangs, there were a variety of problems -- like intermittent under-extrusion, particularly on solid infill, curling of overhangs, poor bridging, and problems at layer start/end (bad seams). Increasing the cooling fan speed (filament settings) and decreasing the perimeter speed to 15mm/s (print settings) helped with the overhangs, but I was still seeing intermittent under-extrusion in some areas, blobbing in others, and ugly seams that various retraction parameter changes didn't address.

Then I decided to take a look at another profile: the Prusa-provided "NinjaTek Ninjaflex TPU @Template". To my surprise, the MVS in that profile was only 1.2, vs. the 3.5 in the @MK4 profile. However, the Template was missing some other desirable settings, like lowering the default detraction speed and increasing the default retraction length.

After reviewing that, I decided on a new approach:

- I loaded the Prusa-provided "NinjaTek Ninjaflex TPU @MK4" printer profile again, along with the default "0.20 Quality @MK4 0.4" print profile.

- I changed the filament diameter to the actual measurement of my Ninjaflex (1.72).

- I changed the "Max Volumetric Speed" from the profile's 3.5 value to a much slower 1.5.

I printed a 3dBenchy, and it was near perfect -- some minor stringing in a couple locations and a little droop on the forward cabin window, but really a great result for Ninjaflex. The only negative was that it took 2 hours and 3 minutes. My previous attempts, trying to keep MVS around 2.7, were 20-35 minutes faster, but all of them had pretty major defects -- particularly at layer start/end points.

So... If speed isn't an issue, just using the default profile and lowering the MVS from 3.5 to around 1.5 is an easy route to a decent print. If higher speed is needed, the MVS can be increased up to about 2.7, but jamming needs to be mitigated (higher nozzle temp, lower flow, and lower detraction speed all help), and some print profile changes (such as lowering perimeter speeds) will help with quality, but some amount of print defects will need to be accepted.

I apologize to the OP for taking this thread so far off the original point -- which was asking about higher MVS with 95A. In an effort to get back on the tracks, I have printed some Cheetah 95A on the MK4 but only at an MVS of around 6. Over the next few days, I'll try to do some more testing with that, and see what kind of speeds I can achieve with it.

RE: Printing TPU on the MK4

I spent some time yesterday and today testing the MK4 (0.4 nozzle) with NinjaTek Cheetah (95A).

This is going to be a long post... But to address the OP's ( @FocusOnTheSun ) question, the summary is that I could not print Cheetah 95A with a Max Volumetric Speed (MVS) beyond 9.0 without jamming. And that 9.0 required boosting the print temperature to 248, which makes for a lot of oozing and stringing.

Test procedure:

- Started with Prusa-supplied NinjaTek Cheetah TPU @MK4 profile, and the Prusa-supplied 0.30mm Draft @MK4 0.4 print settings.

- Boosted the temp to 248, turned off retraction, and boosted MVS to 10.5.

- Sliced a 60x60 square with 5 solid bottom layers, to get some sustained solid infill.

- Verified in the slicer that the solid infill was hitting the MVS speed specified.

- Printed, observed results (i.e., jamming, infill quality, oozing/blobbing, etc.)

- Reduced MVS, reprinted, re-observed.

At 248C, I had jams at anything above 9.0 MVS. At this temp, and with no retraction, oozing and blobbing was pretty bad as well. When the nozzle moved across the 60mm square to start the next layer, there was a blob where it stopped and a huge string (maybe 1/2 the diameter of an extrusion line) that was very visible even when covered by infill. Obviously lots of pressure in the nozzle.

Lowering the temp to a more normal 240C, I had jams anywhere above 8.0 MVS. At 8.0, it printed -- but there was visible under-extrusi0n in the solid infill, where the extrusion lines were thin and not touching each other. And oozing was still pretty bad; there is just so much pressure built up in the nozzle at this speed that it just keeps flowing during moves. If speed is paramount, 8.0 would likely work without jamming, though this could depend on the particular part design. And it would have some sparse infill and lots of ooze-related defects.

Still at 240C, getting down to 7.5 started looking better. There were still some infill areas that were not solid, and still a lot of oozing during moves. I decided at this point to re-enable the 2.2mm retraction from the Prusa-provided profile. This helped a bit with the oozing but made the sparse infill problem a little worse -- at least at the start of the layer, right after the retraction. It just takes a while for the pressure/flow to resume upon detraction.

At 240C, I eventually had to lower MVS all the way to 6.4 to get reliably solid infill. At this speed, the 2.2 retraction also handles most of the ooze so the print looks a lot better. If quality is valued over speed, I would say MVS 6.4 or slightly less is where you want to be. (Coincidentally -- this is the setting Prusa uses in their "NinjaTek Cheetah TPU @MK4" filament profile!)

Next, I decided to print a 3DBenchy. For this, I reverted to the default Prusa-supplied NinjaTek Cheetah TPU @MK4 and the Prusa-supplied 0.20 Quality @MK4 0.4 print settings. All at defaults, including that 6.4 MVS in the Prusa Cheetah profile.

At those default settings, the 3DBenchy was not that bad. No issues with the hull or portholes. There was some stringing, particularly at the aft cabin window. The walls of the cargo box were not bonded together (under-extrusion), and there was a huge droop (~3mm) on the forward cabin window bridging. The seams were very visible; some were over-extruded and some were under-extruded depending on location and exactly where the retractions/detractions occurred.

I went through several iterations, changing a variety of settings, and eventually ended up with a very nice print. I was able to address all but (1) of the noted issues with just changes to the Filament profile:

- Started with Prusa-supplied NinjaTek Cheetah TPU @MK4 profile.

- Raised bed temperature from 50 to 55. (Textured bed.)

- Increased the extrusion multiplier from 1.05 to 1.10.

- Set the diameter to my measured filament diameter.

- Increased Retraction Length from 2.2 to 2.4.

- Decreased Retraction speed from 60 to 40.

- Increased Detraction speed from 20 to 25.

- Decreased Max Volumetric Speed from 6.0 to 5.0.

- Increased Fan Max from 60 to 65.

- Decreased Fan Min from 60 to 50.

That address most of the issues. There was still some slight stringing, but nothing unusual for TPU and easily addressed with a heat gun. The one remaining issue not addressed by those changes was the bad bridging on the top of the front cabin window. I also wanted a single seam. So to solve those two items, I made a couple changes to the Print Settings:

- Started with the Prusa 0.20mm QUALITY @MK4 0.4

- Decreased "Bridge Flow ratio" from 1.0 to .075

- Changed Seam Position from "Aligned" to "Rear" (and positioned the 3DBenchy with an aft corner to the rear of the bed)

The bridge flow ratio helped immensely with the bridging, pulling it tight and eliminating most of the sag. And the seam is certainly visible, but it is small and straight.

As mentioned above, I experienced a lot of jams when testing the faster speeds. Each time, the problem was the filament doubled-over just below the drive gear and lower idler bearing. There is a little too much room here -- soft filament is not sufficiently constrained. That, along with the pressure needed to push everything through a 0.4 hole is pretty limiting. A 0.6 nozzle is probably a better choice!

Also, Jams are NOT FUN TO FIX on this extruder. The soft filament can easily get "squished" and pulled in behind the drive gear, where it is very difficult to remove. On one of the jams, I actually resorted to removing the drive gear assembly to get the rat's nest of filament out from behind the gear. If you hear the extruder "clicking" get to it FAST and cancel the print! And then manually remove the filament, as any "kink" can end up getting re-jammed at the top if you use the normal "unload filament" routine.

RE: Printing TPU on the MK4

I've had success with Sainsmart TPU and the profile provided by Prusa in the filament profiles. I haven't had to change anything, not even for loading the filament

RE: Printing TPU on the MK4

Same with the Amazon Basics TPU. Those firmer TPU materials (95-98A) can be driven at the ~6 MVS range used in the default profiles. But for NinjaFlex (85A), the Prusa profile does not work -- it tries to push the filament way too fast and causes jamming in the Nextruder.

I've had success with Sainsmart TPU and the profile provided by Prusa in the filament profiles. I haven't had to change anything, not even for loading the filament

RE:

Hi everyone!

I'm curently printing 85A TPU with my MK4 (just a simple cube for now) with the same parameters I used to use with my MK3s.

If results are good, I can show you my settings if you want.

For information (and for @ScottW - by the way my name is Scott too, and my last name starts with a W ahah): when I slice a Benchy with my settings, it's telling me that it would take 1h42 to print.

I was worried that this MK4 could not handle soft TPU but it seems to work as good as my MK3s. 🙂

RE:

Hello @scott-18! Very interested in seeing your results!

Where I had the most trouble with NinjaFlex 85A (the only brand 85A I tried) jamming was on parts that had "sustained periods of high flow"; for example, something with a large footprint and several solid infill layers. That's where "flow" became the limiting factor. More complex parts, or parts without much solid infill, were less of a problem. First layer slows down for adhesion, so it wasn't an issue, but large successive layers were where I usually saw the jams.

I think the "sustained high flow" periods are where the pressure (compression) built up, and eventually led to filament buckling / jamming above the feed tube on my MK4.

Specific to the 3dBenchy, the 2hr 3m I quoted was using the default 1.5 MVS from Prusa's Ninjatek "template" profile. I was able to bring that down to 1hr 40m by increasing MVS to 2.7 without jamming, but there was a bit more stringing and the seams did not look as good.

Looking forward to your results!

RE: Printing TPU on the MK4

My TPU needs to dry (I heard bubbles while printing resulting with small artifacts) before doing more tests.

I will do that tomorrow and print a Benchy (or at least something more interesting than a cube) with my settings to validate before posting them.

I keep you in touch and will pu more details tomorrow!

RE: Printing TPU on the MK4

Amazon basic tpu with 95 shore prints absolutely problem-free. With the right profile in the prusa slicer. Even increased the speed. I'm very excited about the Mk4.

RE: Printing TPU on the MK4

Amazon basic tpu with 95 shore prints absolutely problem-free. With the right profile in the prusa slicer. Even increased the speed. I'm very excited about the Mk4.

Agreed. As I mentioned in post#3, I did a 3DBenchy with that stuff (in Red) using the Prusa-supplied profile and it came out great!

The Amazon listing doesn't specify the shore harness. User reviews have estimated 95-98, and I would say closer to 98 because I have some Cheetah (95A) and the Amazon stuff feels a little harder than that. In any case, it is nice stuff -- prints really well, and available at a decent price.