Any experience with Filaflex Foamy filament?

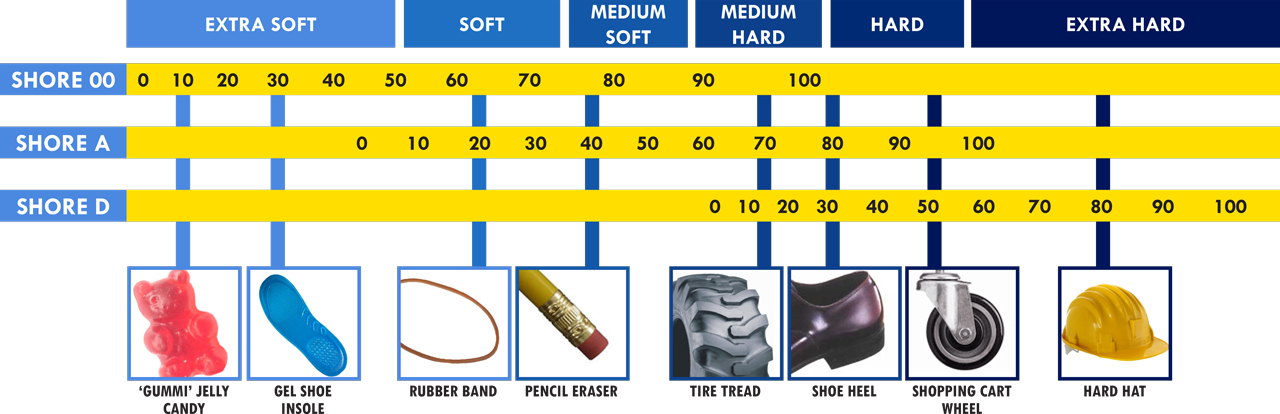

I am looking for a filament that gives me a significantly lower stiffness than the Fiberlogy Fiberflex 40D I use now. Yes there's also a 30D variant but I look for a larger change. The below diagram, probably well known, and for what it is worth, gives an indication of comparable Shore A hardness of 86 or so. Most manufacturers give hardness in ShoreA.

I do realize that too soft filament does not print easily, and that's why I looked at Recreus Filaflex Foamy, which comes at 78 Shore A , so ballpark near the 30D FiberFlex, but, depending on the flow rate, this stuff is said to foam up and settle at a lower hardness which can be down to 51 Shore A.

Does anyone have any experience with using this type of filament on an MK4? Any do's and dont's?

Also, do you have any idea of the coefficient of friction (COF) of the material relative to steel or wood? I need to make some 'grippers'. The softer the material the larger the contact area and that usually helps to increase grip, but if the surface COF is reduced also the effect may be smaller than expected.

RE:

I've just received a new roll today and stumbled on your topic when searching for instructions. There are surprisingly little reviews about this filament and not even a proper manual from Recreus. I really need some tables and graphs with temperatures, flows and especially prints speeds (I find no info on how fast I should print)

I bought it for the exact same reasons as yours. I've been working a lot with Fiberlogy's 40D and 30D Fiberflex filaments. Holding them side by side I notice that the Filaflex foamy is:

- About as soft as the 30D filament and noticably softer than the 40D

- Sadly it grips a good deal more onto stainless steel than the Fiberflex 30D filament (I've rubbed it on a stainless steel knife blade) and that is known for getting stuck in full metal hotends (I could not get it to print in my Dragon hotend on my dyi printer)

I'm about to give it a try in my Bambulab X1, which handles Fiberflex 30D just fine but I'm still a little bit scared

I'll try and not to forget keeping you posted

RE: Any experience with Filaflex Foamy filament?

I've found some tables

https://drive.google.com/drive/u/0/folders/11cDz7cxMjDm0m32_UBHOhmARtT-R0gJ5

RE:

First test last night had an almost ok result. At work now so I haven't got any pics yet

I used 250°C - 30mm/s at 65% flow which resulted in quite some underextrusion. You can clearly see the walls not touching each other and some layers have so much underextrusion that they split when I pull on them (and that's also how I noticed the walls not touching)

Next test will be at 70% flow and 20mm/s. If that doesn't give me good results, I'll have to remove my reverse bowden setup to feed the filament straight into the extruder from the top because when yanking on the filament (extruder side) I do get quite a lot resistance and therefore the filament stretches more, possibly causing the underextrusion

as for how it feels, well, very soft. A LOT softer than the 30D, nice matte outside texture and very low layer line visibility.

You can feel the softness is caused by the gas bubbles inside the filament, it's really a unique feel.

RE: Any experience with Filaflex Foamy filament?

Thanks for the reply.

The lack of technical data indeed can be frustrating. One would expect that the manufacturers provide good instructions help the introduction of the material.

The values in the table suggest that they expect the added volume of the bubbles makes up for the under-extrusion. I understand from your comments this is not necessarily the case, so indeed speed reduction, so the filament spends more time in the hotend so it can more fully foam up, may be the answer.

RE: Any experience with Filaflex Foamy filament?

Did 70% flow do the trick?