X Axis Innaccuracies?

I've been printing for some time and have a Prusa MK3 and a MK4. I built both from kits and have had many successful prints with the MK4. Recently I noticed my MK4 X axis seems to have some inaccuracies:

I just tuned the X axis belt again thinking that was the problem. It's currently reporting as "just right" and I'm still getting this result - only on the X axis. Do I just keep retuning? Is there something obvious I'm forgetting?

My Y axis looks great by comparison:

Thanks for any help!

Best Answer by blauzahn:

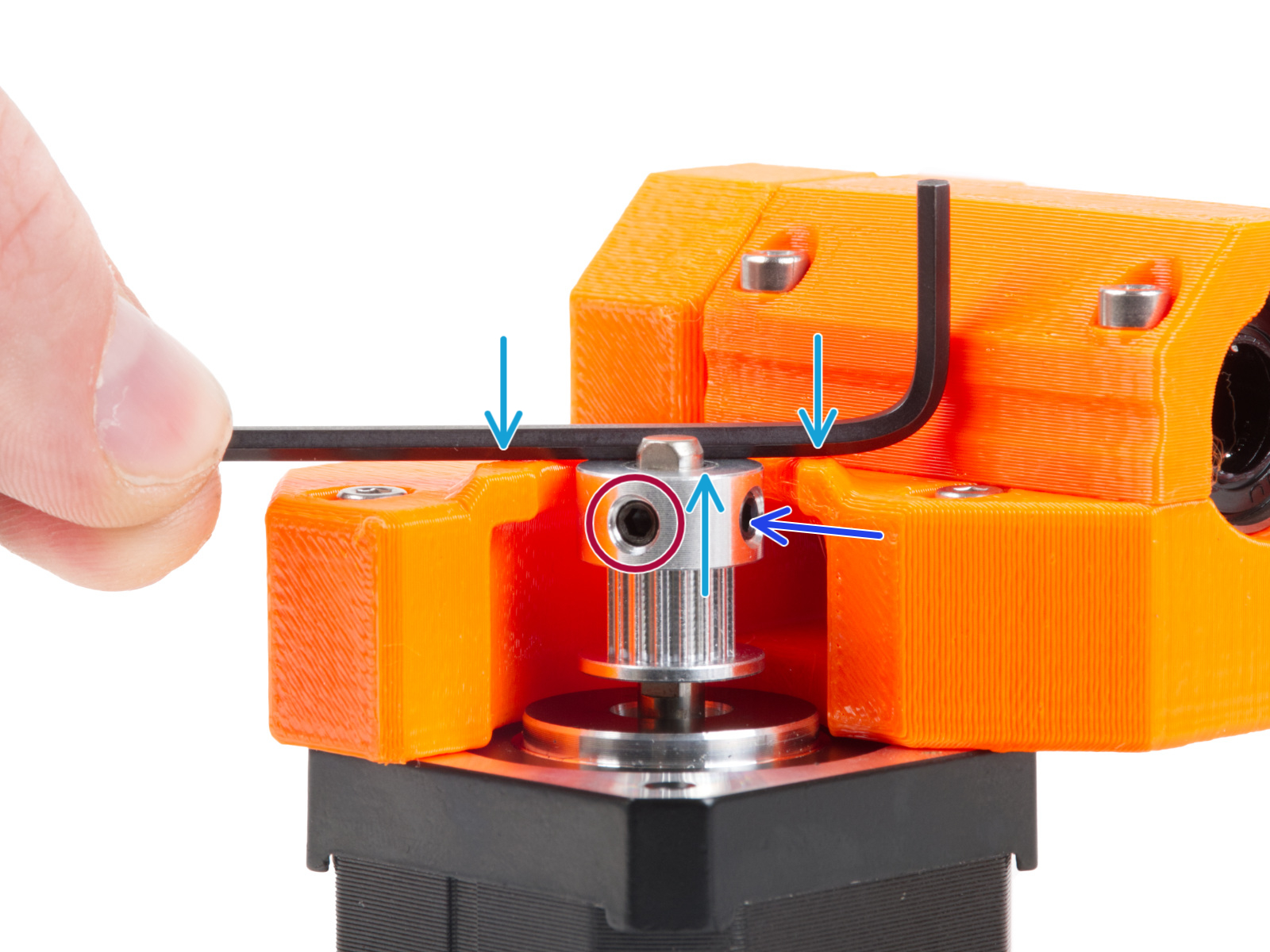

Yes, it would but start with the grub screws. Please remember, that the stepper shaft has a D-shape and one grub screw is supposed to sit on the flat side. Wiggle them down nicely. In case they became loose, please consider using loctite (blue) or similar. Verify that the belt is running straight and does not run heavily into the pulley sides.

A defective linear bearing can also ride rough. I once had a defective upper x-rod showing a visible groove. Did you grease the linear bearings? Feeling, whether idler and x-axis run smoothly is done best with the belt taken off so that the pulley is disengaged anyhow. That is also an opportunity to feel, whether the stepper axis runs smooth nor not. Unless the motor cable is broken, I estimate a defective stepper as unlikely. I would definitely try more probable simple things first before swapping motors.

RE: X Axis Innaccuracies?

That is really strange. My initial thought was the belt but you have looked at that. That leaves the stepper motor. Maybe you could try swapping the X axis motor with the Y axis and see if the issue moves with the motor. It’s a bit of work with the hex wrench but should help with the diagnosis. Lets us know how it goes.

RE: X Axis Innaccuracies?

Please check the grub screws (set screws) of the pulley. The bearing of the idler might also be defective.

RE: X Axis Innaccuracies?

I will give these a shot tonight. Swapping axis motors seems like a lot of work, I'll try that last.

How would I know if the bearing of the idler is defective? Would it ride rough?

RE: X Axis Innaccuracies?

Yes, it would but start with the grub screws. Please remember, that the stepper shaft has a D-shape and one grub screw is supposed to sit on the flat side. Wiggle them down nicely. In case they became loose, please consider using loctite (blue) or similar. Verify that the belt is running straight and does not run heavily into the pulley sides.

A defective linear bearing can also ride rough. I once had a defective upper x-rod showing a visible groove. Did you grease the linear bearings? Feeling, whether idler and x-axis run smoothly is done best with the belt taken off so that the pulley is disengaged anyhow. That is also an opportunity to feel, whether the stepper axis runs smooth nor not. Unless the motor cable is broken, I estimate a defective stepper as unlikely. I would definitely try more probable simple things first before swapping motors.

RE:

I started down the path of disassembling the extruder so I could get access to the part of the X carriage that holds the belt when I noticed that the pulley on the motor shaft had slid out to an incorrect position.

Correct position:

My position:

After fixing this a first (small) test print looked good last night. I'll step into some more prints today to ensure it's all set.

Thank you both for the suggestions!

RE: X Axis Innaccuracies?

Well done. Thank you for the feedback.

RE: X Axis Innaccuracies?

With this latest print, I'm ready to call this a success. Bang on straight X axis as shown here:

Thank you all for your help. I hope this helps someone in the future! Be sure to check your motor-side pulley position & get those grub screws tightened up!